Automatic container system

An automatic container and motion system technology, applied in transportation, packaging, storage devices, etc., can solve the problems of low degree of automation and small storage capacity, and achieve the effect of small footprint, large capacity, and comfortable shopping experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

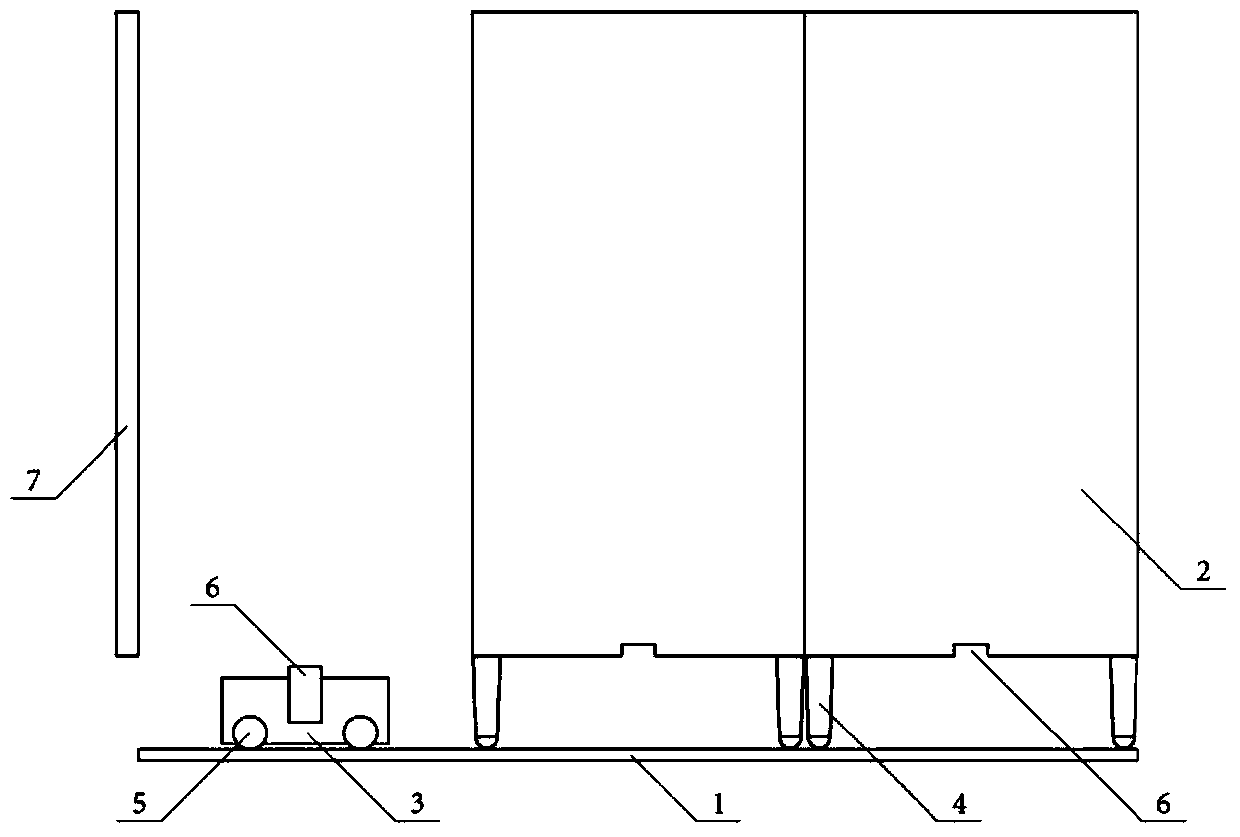

[0069] The first embodiment of the present invention provides an automatic container system, please refer to figure 1 ,include:

[0070] The rail rack 1 is arranged on the bottom surface of the automatic container system or on any two opposite sides. For example, the rail rack 1 is specifically the floor of the warehouse, and the cargo access port 7 is arranged at the warehouse gate.

[0071] A number of containers 2 are movably arranged on the rail frame 1, and at least one space larger than or equal to the size of the container 2 is freed for the mobile switching of the container 2. At least one surface of the container 2 and the rail frame 1 is provided with sliding The device 4 is used to allow the container 2 to move freely on the rail frame 1. For example, a number of containers 2 are specifically two containers 2 close to one corner of the warehouse, and the free space of the warehouse is larger than one container space. A sliding device is provided on at least one surface of...

Embodiment 2

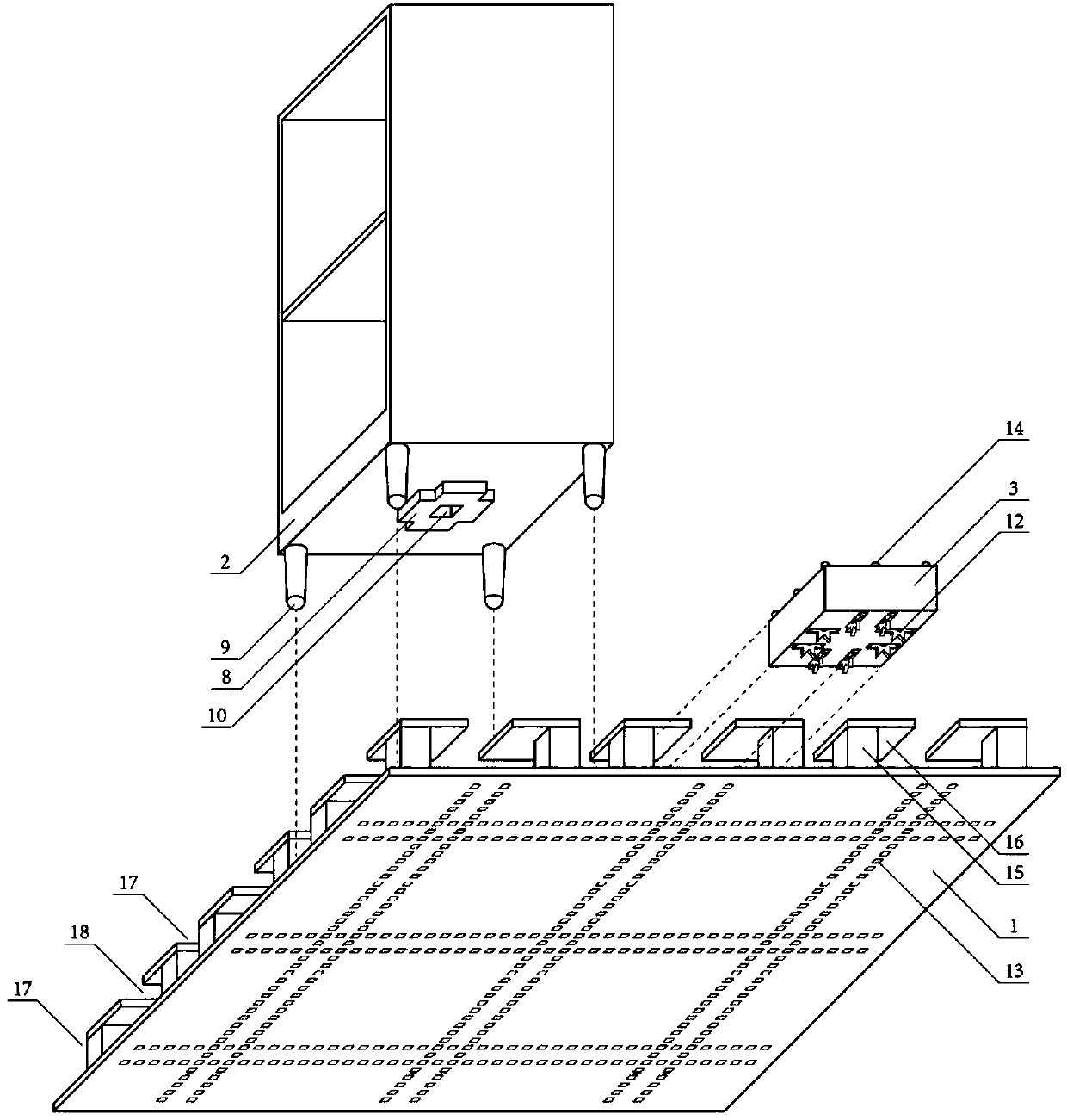

[0095] The second embodiment of the present invention provides an automatic container system, please refer to figure 2 , Figure 4 with Figure 5 ,include:

[0096] The track frame 1 is arranged on the bottom surface of the automatic container system or any two opposite sides.

[0097] A number of containers 2 are movably arranged on the rail frame 1, and at least one space larger than or equal to the size of the container 2 is used for the mobile switching of the container 2. At least one surface of the container 2 and the rail frame 1 is provided with sliding The device 4 is used to allow the container 2 to move freely on the rail frame 1.

[0098] At least one cabinet shifter 3 is movably arranged on the rail frame 1, and a movement device 5 is provided on the cabinet shifter 3 to allow the cabinet shifter 3 to move freely on the rail frame 1.

[0099] The connecting device is used to connect the container shifter 3 with the container 2 and drive the container 2 to move.

[0100] A...

Embodiment 3

[0122] As a preferred solution, the third embodiment of the present invention provides an automatic container system. The difference from the second embodiment of the present invention is that, please refer to Picture 9 , Picture 10 ,Also includes:

[0123] At least one loading and unloading device 21 is arranged on at least one side of the rail frame 1 for loading or unloading goods from the container 2. The loading and unloading device 21 includes a driving gear 24 and a conveyor belt 22a with a transmission gear 23, which is movably fixed on the two sides. One-dimensional motion system 25 or one-dimensional motion system, the two-dimensional motion system 25 or one-dimensional motion system is arranged on the side of the track frame 1, including a transverse motion mechanism and a longitudinal motion mechanism or only a longitudinal motion mechanism, used to drive the gear 24 And the conveyor belt 22a moves freely on the side of the rail frame 1.

[0124] The container conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com