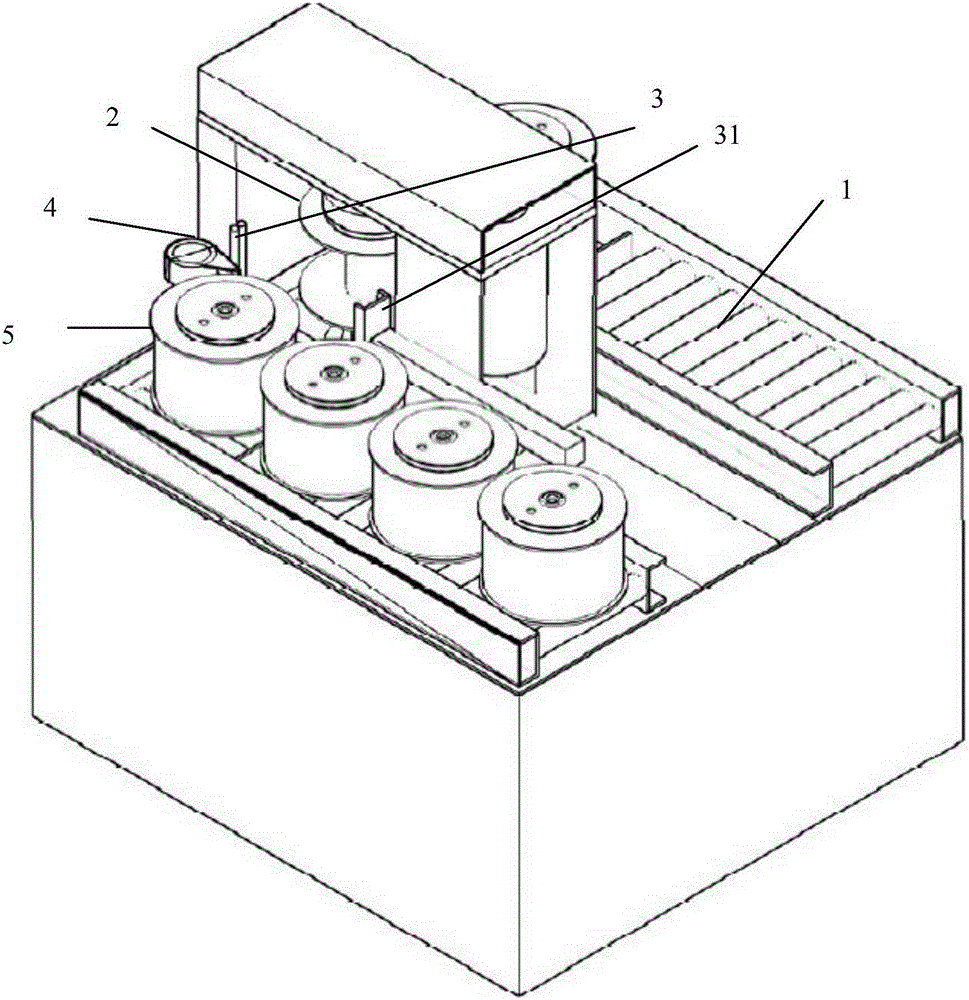

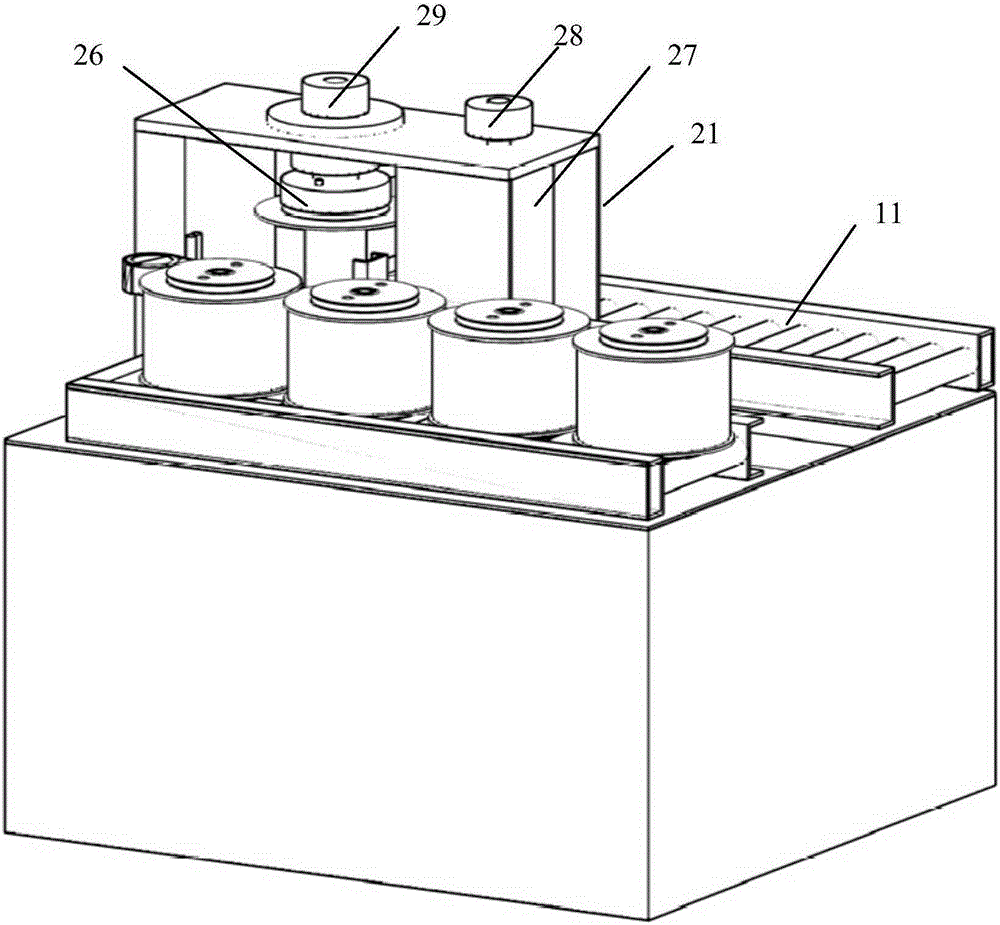

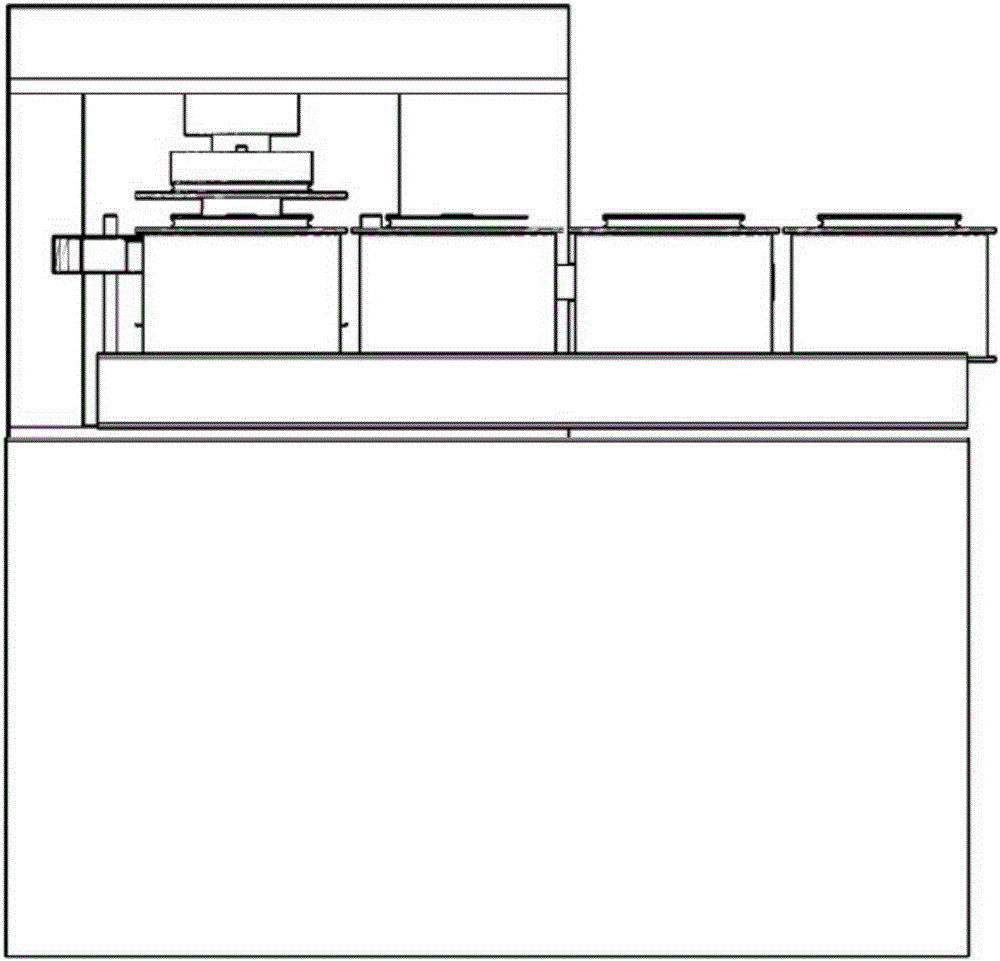

Automatic wheel replacing take-up machine

A wire take-up machine and automatic technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of reducing the service life of the machine, increasing labor intensity, easy rolling and deviation, etc., to achieve extended use Long life, high degree of automation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the prior art, the I-shaped wheel is placed horizontally during the entire operation process. The contact mode of the I-shaped wheel and the conveyor is a point contact method. It is prone to rolling and offsetting during the conveying process, and the upper wheel cannot be correctly realized. , Unloading the wheel, and taking up the line, the stability is poor, especially when the spool needs to be transferred from the machine to other equipment during the work, it can only be realized with manual assistance. The workload is large and the labor intensity increases, which seriously affects work and production efficiency. Moreover, in the prior art, the empty spools are clamped and fixed by the cylinders with opposite sides. When the spools are fully wound and unloaded, the cylinders on the opposite sides are released at the same time. The damage to the machine is especially obvious when the free fall directly hits the machine, especially when it is on the market. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com