Tray transferring mechanism

A pallet and transfer technology, which is applied in the direction of conveyors, conveyor objects, and object destacking, etc., to achieve the effects of reasonable structural design, improved efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

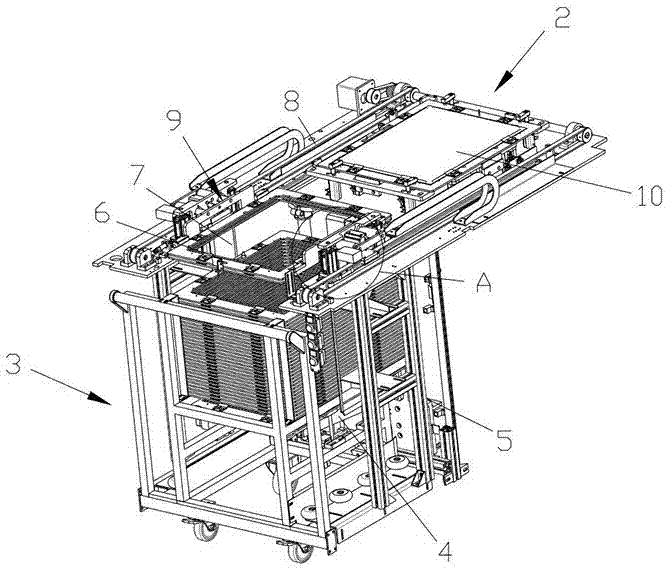

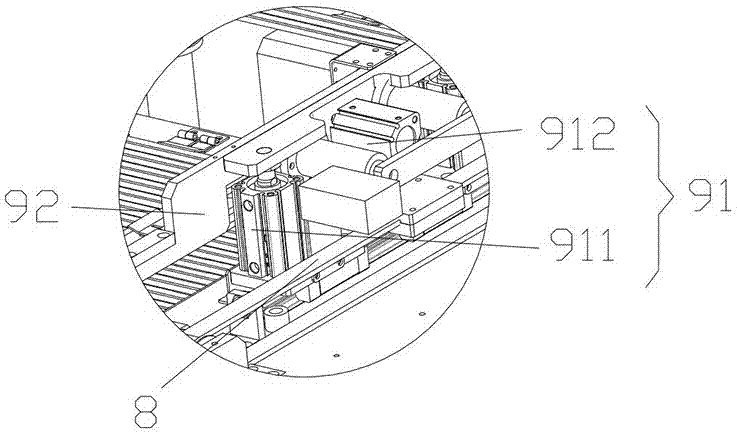

[0024] A pallet transfer mechanism provided by the present invention includes a tray 3 for placing the tray 1, a transfer platform 2 for carrying the tray 1, and a tray 1 for transporting the tray 1 between the transfer platform 2 and the tray 3. The transfer assembly of the transport, the transfer assembly is provided with two first guide rails 8 and two chuck parts 9 that are respectively movably connected to the two first guide rails 8, and the two chuck parts 9 are used for clamping Hold the two sides of the tray 1; the four sides of the transfer platform 2 are provided with a jacking cylinder 21 for opening the tray 1, and the opened tray 1 is used to accommodate the external board 10; the board 10 can be a circuit plate, the transfer table 2 is provided with a pressing arm 22 for pressing the tray 1 and a pressing cylinder 23 for driving the pressing arm 22 to rotate and lift; the transfer table 2 is provided with a stopper 24 for adjusting the tray 1 position of the adj...

Embodiment 2

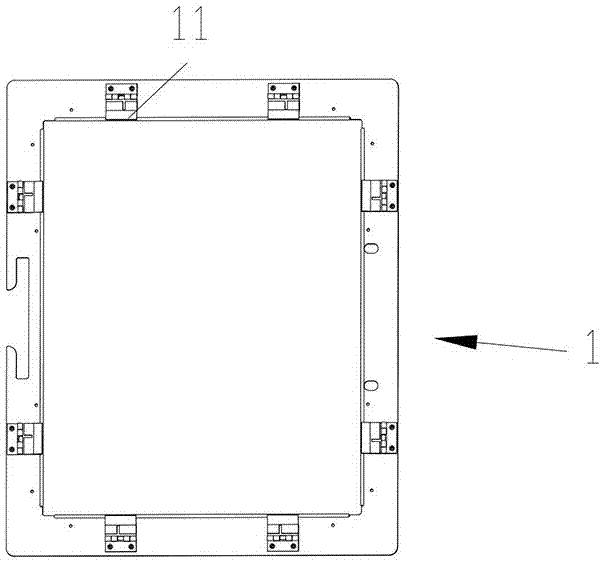

[0029] The difference from Embodiment 1 is that the plurality of pallets 1 are neatly stacked on the tray 3, and when the plate 10 and the pallet 1 need to be loaded, the pallet 1 is clamped by the chuck part 9, and along the The first guide rail 8 transports the tray 1 from the tray 3 to the transfer platform 2 for placement. When all the trays 1 on the tray 3 are clamped away, the tray 3 can be pushed out, and the tray 1 can be replenished and then pushed back to the original position. , to achieve the effect of labor saving and convenience. After being placed, the position of the tray 1 is adjusted by the adjustment plate 25 and the stopper 24, and the position is fixed by the pressing arm 22. Then, the tray 1 is opened by jacking up the cylinder 21, specifically, the pressing arm 22 is used to press the tray 1. Under the tight action, the elastic pressure rods 11 around the tray 1 are lifted up to facilitate the placement of the plate 10. When the plate frame 10 is accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com