Belt filter press for manioc waste

A belt filter press, cassava residue technology, applied in the direction of filtration and separation, moving filter element filter, separation method, etc., can solve the problems of inability to meet the requirements of dehydration and drying, high water content, achieve good dehydration and drying effect, and easy to operate. , the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

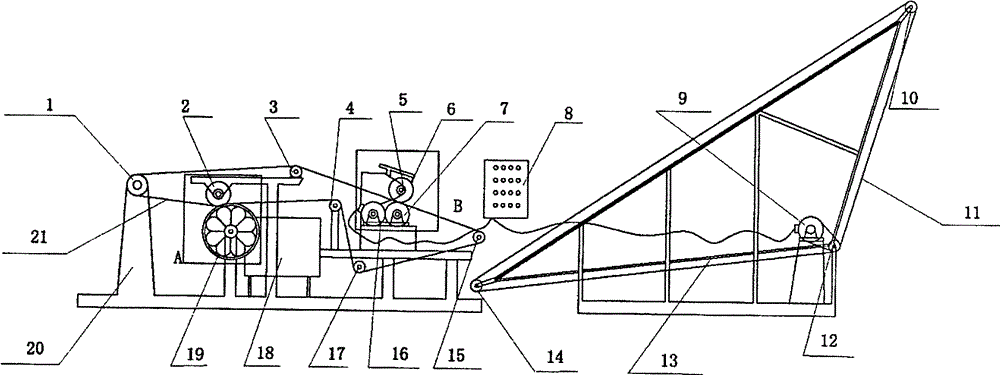

[0008] Further illustrate technology of the present invention below in conjunction with accompanying drawing:

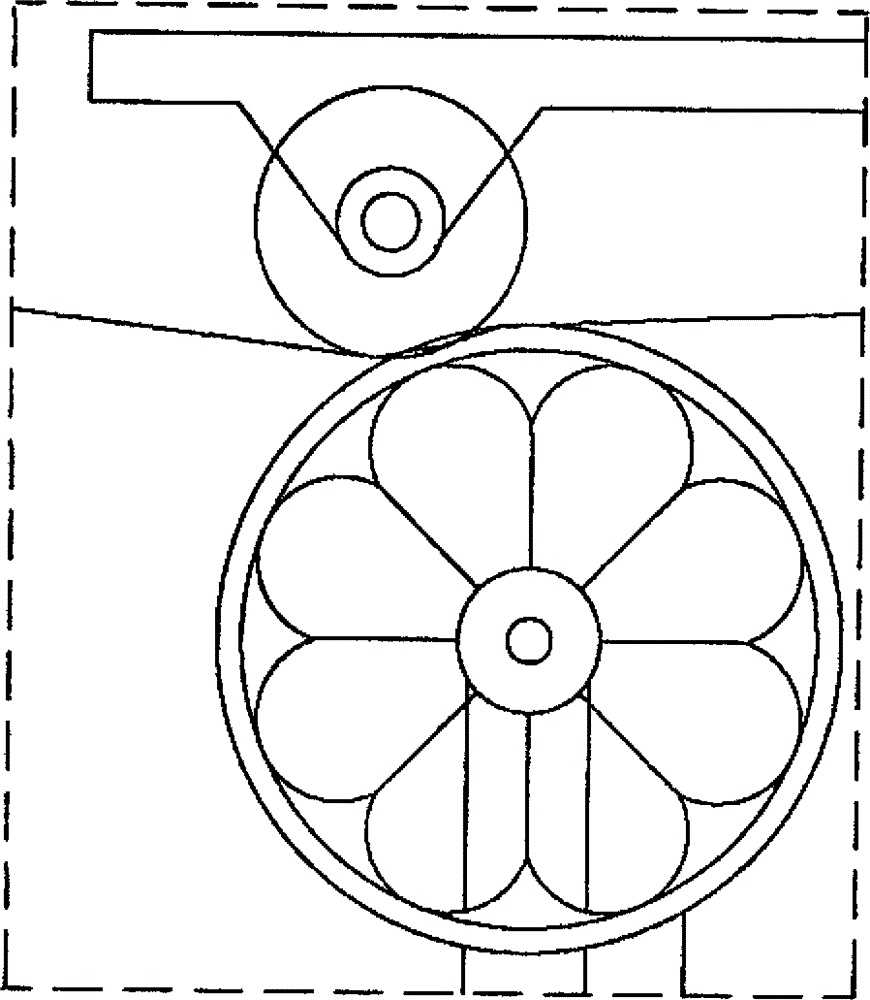

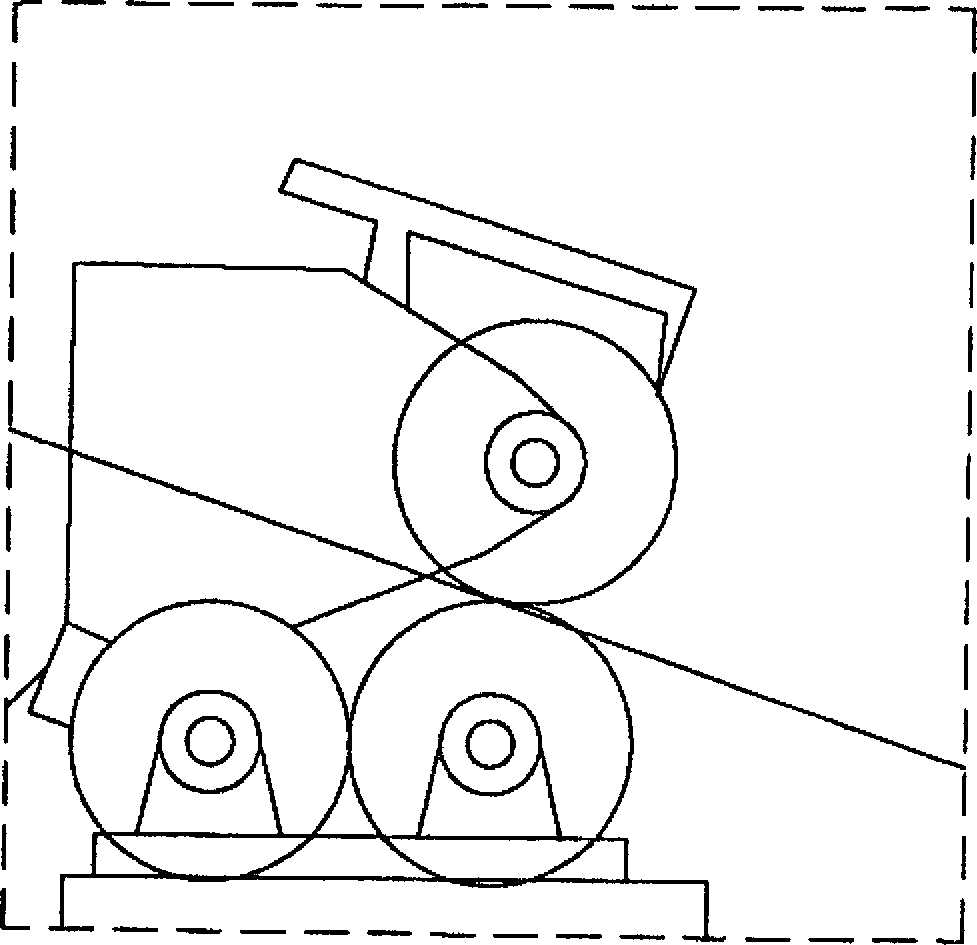

[0009] Cassava slag belt filter press consists of frame (20), motor (16), container tank (18), large roller (19), middle roller group (1, 2, 5, 7), small roller group (3, 4, 15, 17), conveyor belt (21), scraper (6), controller (8), loading transmission frame (13), loading motor (9), loading conveyor belt (11), loading roller group (10, 12 , 14) composition. Fixed motor (16), container groove (18), large roller (19), middle roller group (1, 2, 5, 7), small roller group (3, 4, 15, 17) are installed above the frame (20) Transmission mechanism is made of conveyor belt (11) and large roller (19), middle roller group (1,2,5,7), small roller group (3,4,15,17) and motor (16). The middle roller group is composed of the first middle roller (2), the second middle roller (7), the third middle roller (5) and the fourth middle roller (4), the large roller (19) and the first midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com