Automatic stacking and loading machine for bagged cement

A technology of a loading machine and a palletizing device, which is applied in the field of bagged material handling equipment, can solve problems such as high labor intensity, high enterprise cost, and harsh working environment, and achieve the effects of reducing labor intensity, increasing efficiency, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

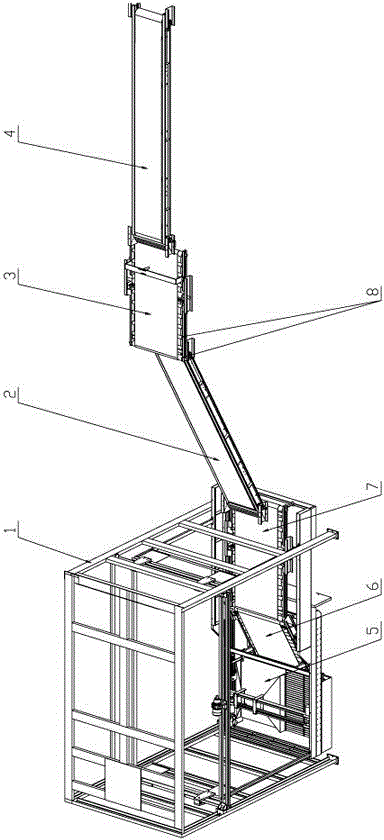

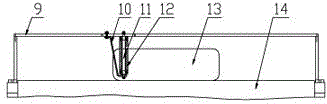

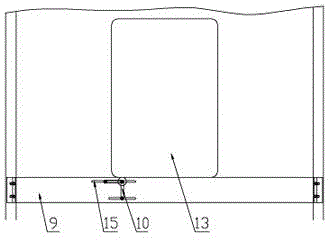

[0038] see figure 1 — Figure 8, the present invention is an automatic palletizing and loading machine for bagged cement, comprising a bag receiving machine 4, an indexing device 3, a lifting coordination device 2, a marshalling device 7, a slide device 6, a palletizing device 5, a lifting device 1 and The master controller, the said bag receiving machine is docked with one end of the indexing device, the other end of the indexing device is rotationally connected with the upper end of the lifting coordinating device, the lower end of the lifting coordinating device is movably connected with the front end of the marshalling device, and the rear end of the marshalling device is connected with The slide device, the lower end of the slide device is aligned with the stacking device, and the marshalling device, the slide device and the palletizing device together perform lifting movement under the action of the lifting device, and the bag receiving machine, indexing device, and mars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com