Multifunctional paving brick pouring and tamping machine

A kind of pavement brick, multi-functional technology, applied in ceramic molding machines, manufacturing tools and other directions, can solve the problems of complex operation process, low work efficiency, high labor intensity of workers, etc., to achieve advanced technology, improve labor efficiency, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

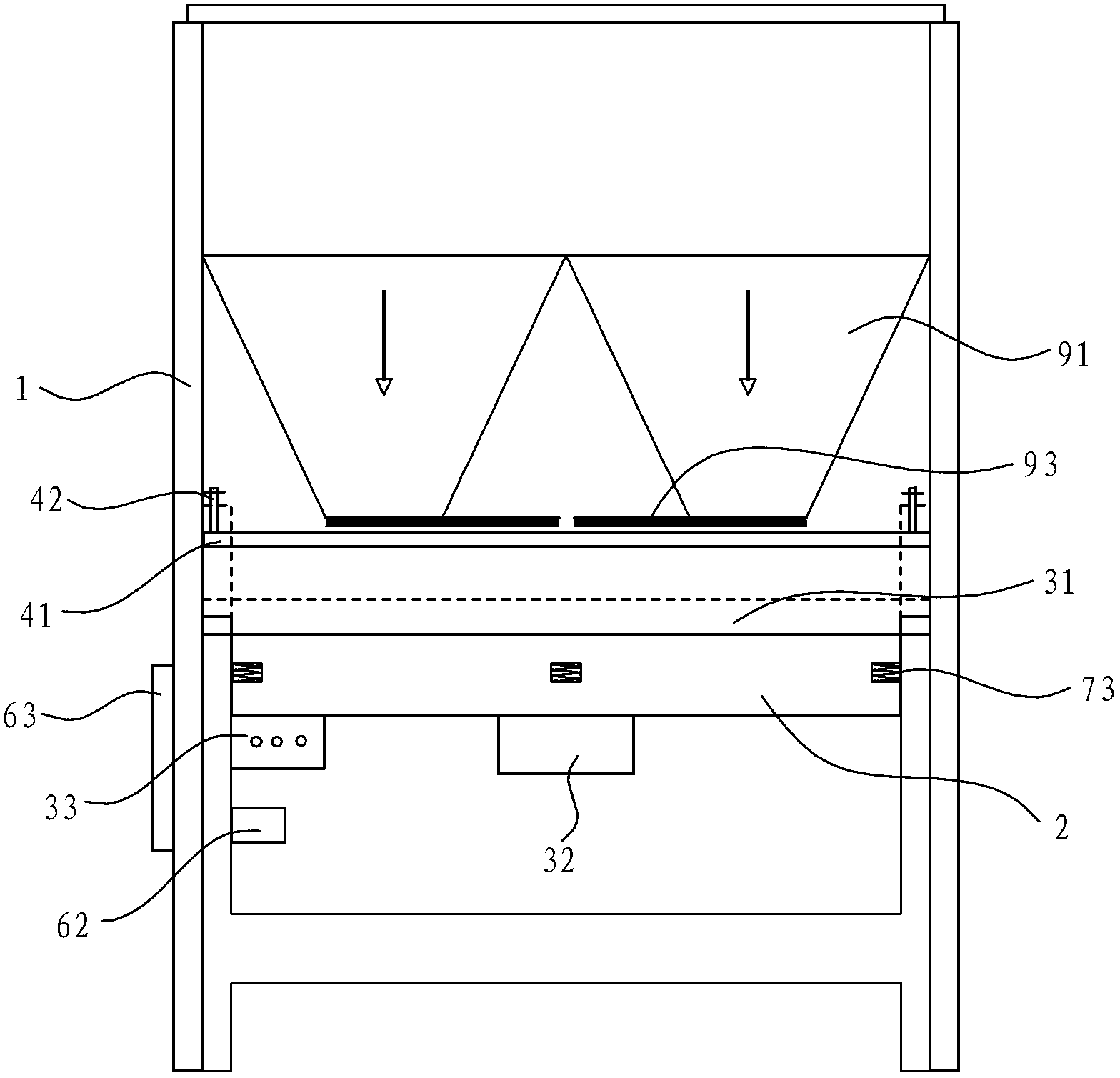

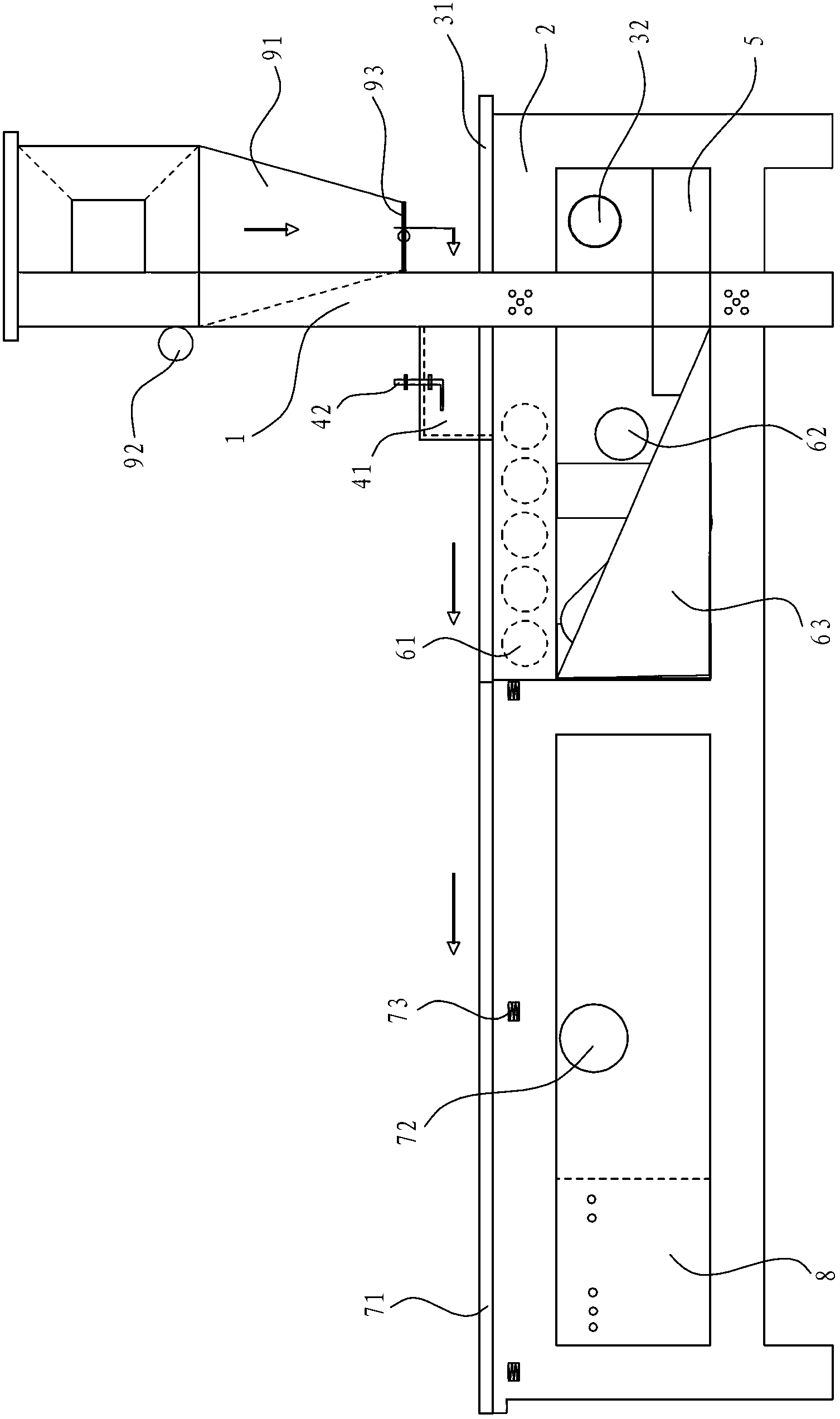

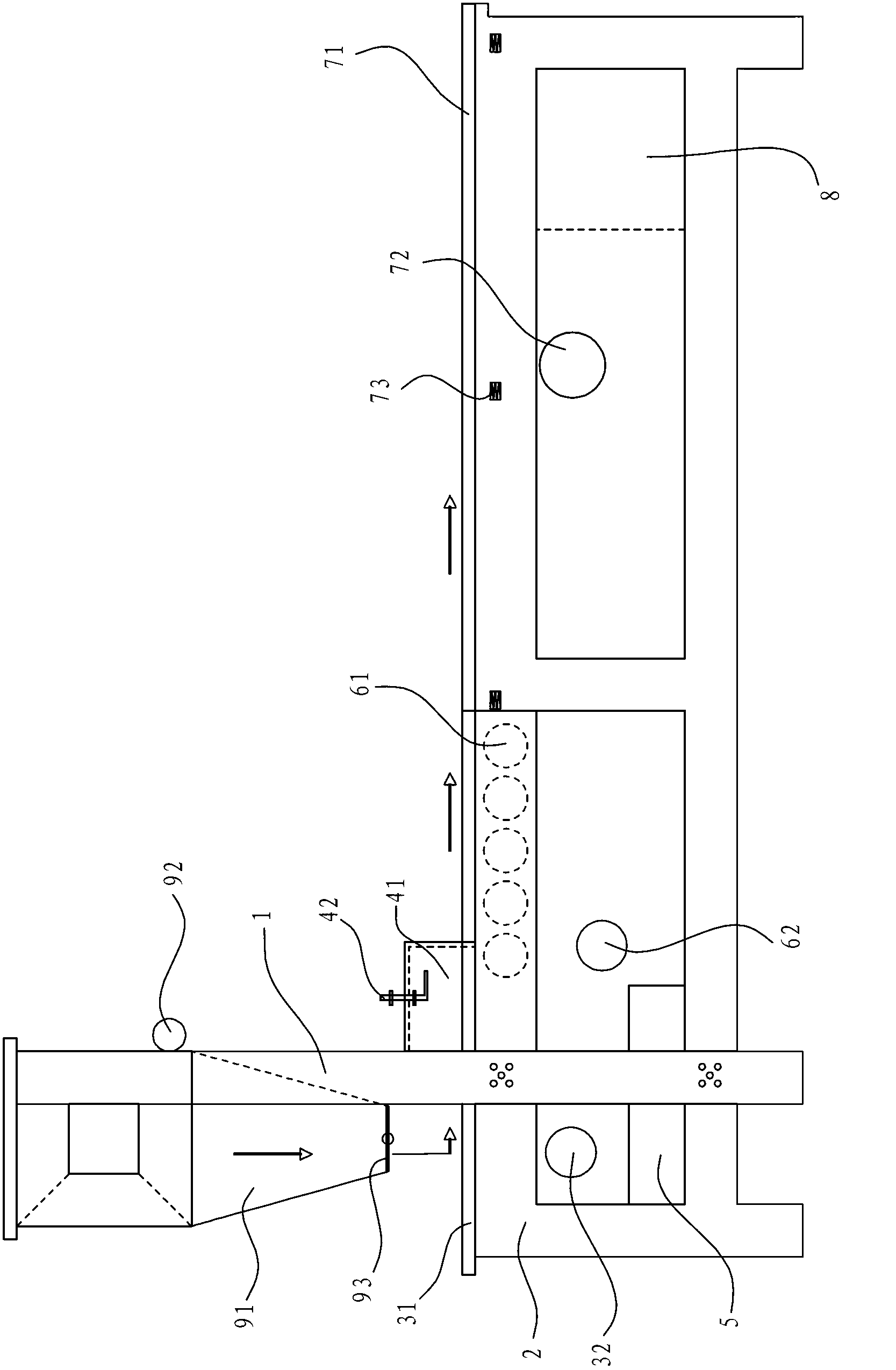

[0022] Such as Figure 1 to Figure 4 As shown, the multifunctional pavement brick pouring and tamping machine includes a frame 1 and a workbench 2 installed on the frame 1, and a feeding mechanism, a vibrating mechanism, a scraping mechanism, a transmission mechanism and The vibrating mechanism, the concrete mixed by the mixer can be automatically loaded after passing through the above-mentioned mechanism in turn. The whole machine has a high degree of automation and can significantly improve work efficiency.

[0023] Feeding mechanism is installed on the rear end of workbench 2 ( figure 2 The top of the right side end), which includes two storage hoppers 91 and a third vibrating motor 92 installed on the frame 1 with the opening facing down. When the third vibrating motor 92 works, it can drive the storage hopper 91 to vibrate, which is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com