Automatic crawler-type loading shovel

A crawler-type, automatic technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as high labor intensity, impossibility, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An automatic crawler-type shovel loader of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The accompanying drawings constituting this application are used to provide a further understanding of the present invention, and the schematic embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute improper limitations to the present invention.

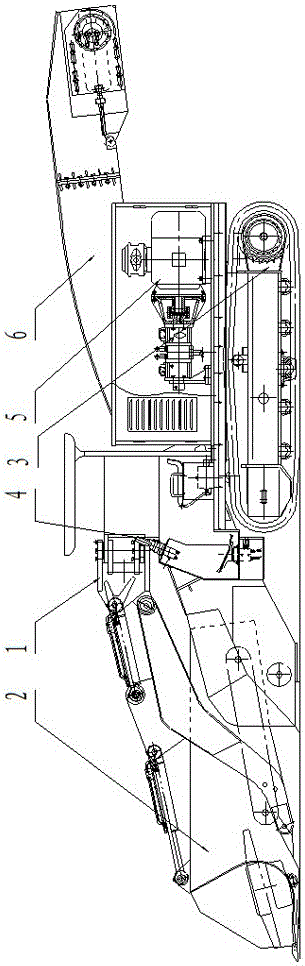

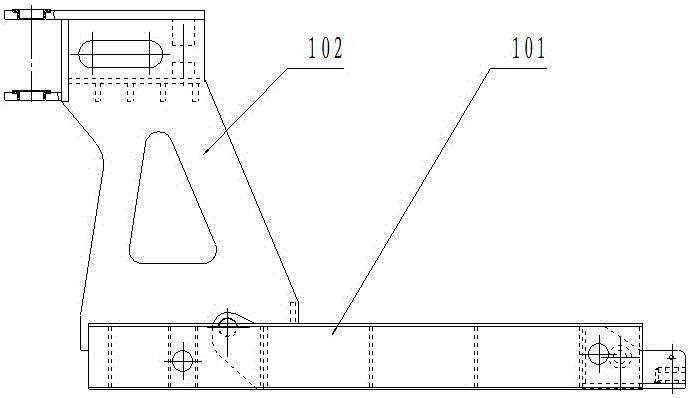

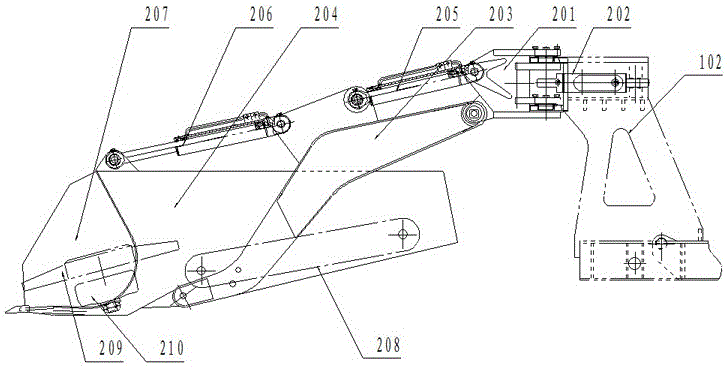

[0024] Depend on figure 1 It can be seen that an automatic crawler-type shovel loader in this embodiment includes a frame assembly 1, a shoveling mechanism 2 arranged in front of the frame assembly 1, a walking mechanism 3 arranged on both sides of the frame assembly 1, a set On the upper left of the frame assembly 1 is the operating mechanism 4 that controls the operation of the whole machine, the power mechanism 5 that provides power for the automatic crawler-type shovel loader, and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com