Classification logistics box automatic loading device

A technology for automatic loading and logistics boxes, which is applied to the stacking of objects, conveyor objects, transportation and packaging, etc. It can solve the problems of no transfer equipment and affect the loading efficiency of logistics boxes, so as to realize automatic loading, improve logistics efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

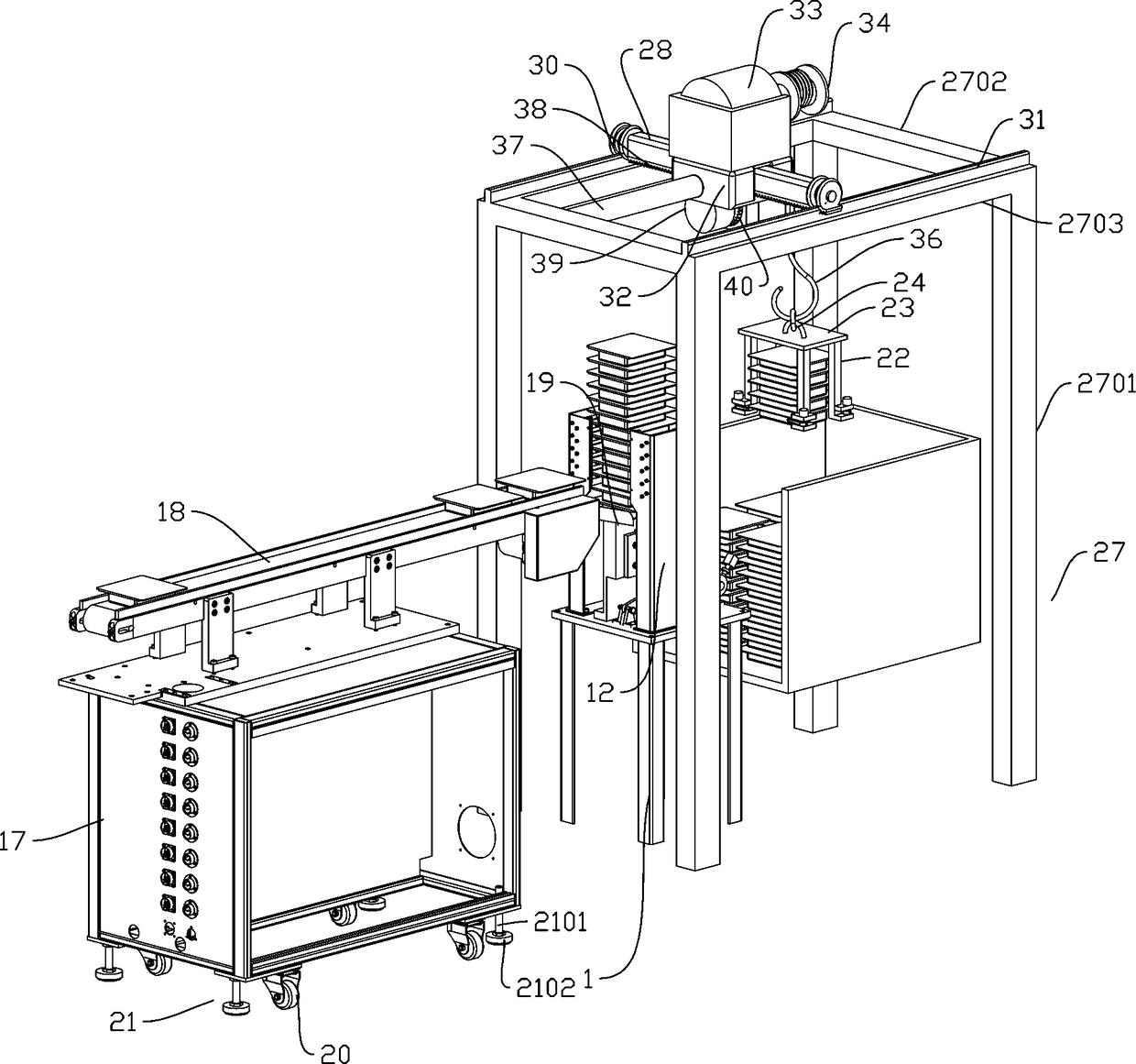

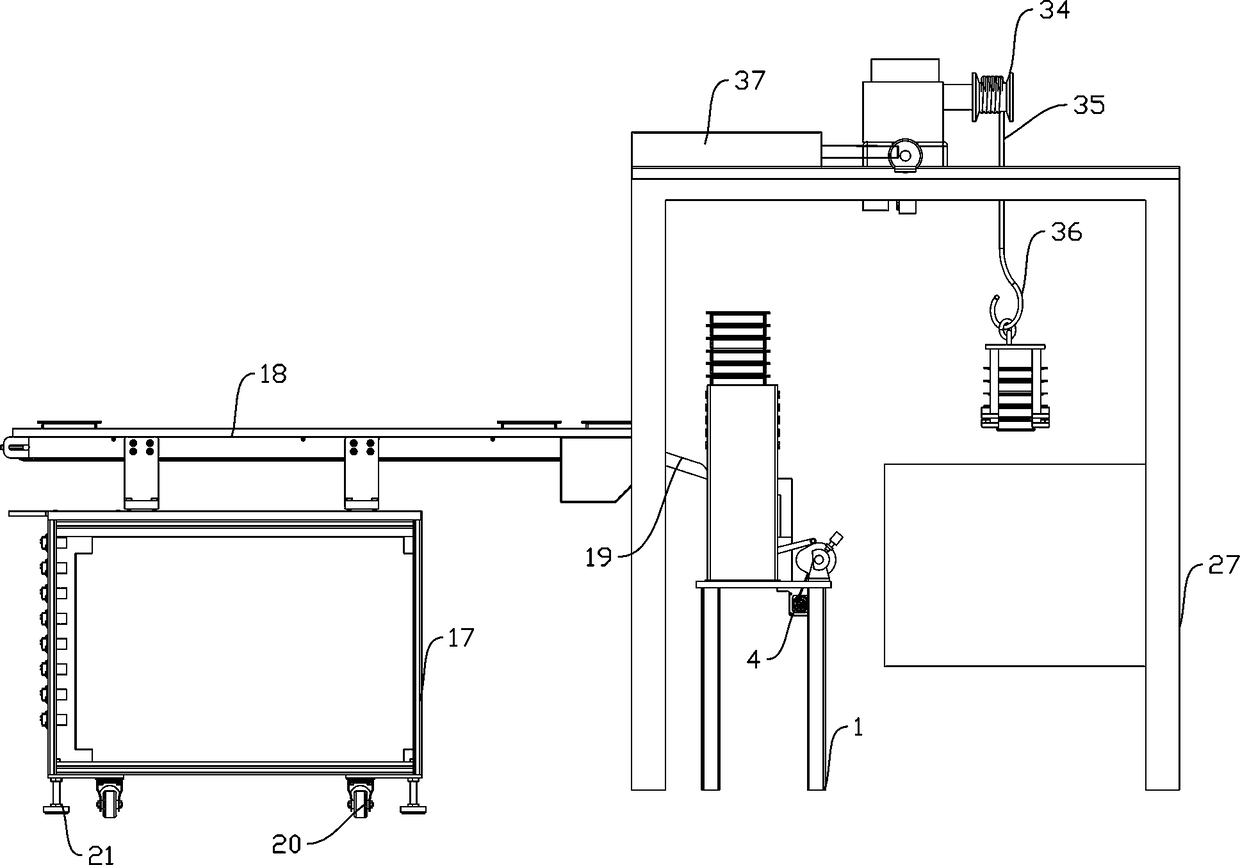

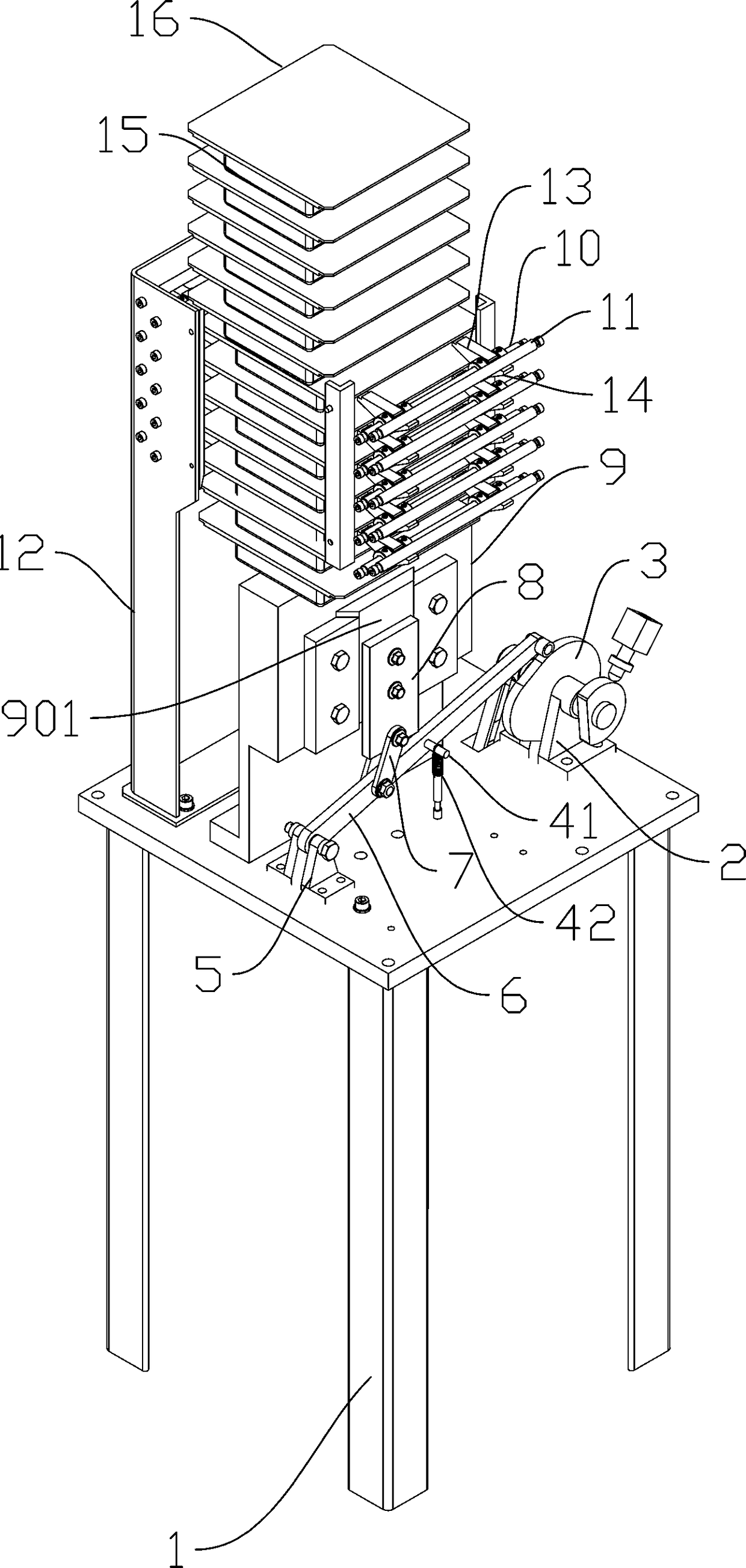

[0023] Such as Figure 1~4 Among them, an automatic loading device for sorting logistics boxes, including a palletizing device, the palletizing device includes a support base 1, a cam frame 2 is provided on the upper side of the support base 1, and the rotating shaft of the cam 3 is mounted on the cam frame 2 through bearing rotation , the rotating shaft of the cam 3 is driven by the first motor 4, and in this embodiment, the first motor 4 drives the rotating shaft of the cam 3 to rotate through a belt transmission.

[0024] A hinge support 5 is provided on the support base 1, and one end of the connecting rod 6 is hinged with the hinge support 5, and the other end leans against the cam 3. Specifically, the end of the connecting rod 6 far away from the hinge support 5 is provided with a hinge along the edge of the cam 3. Sliding pulley, connecting rod 6 and lifting connecting rod 7 are hinged, the hinged position of connecting rod 6 and lifting connecting rod 7 is set between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com