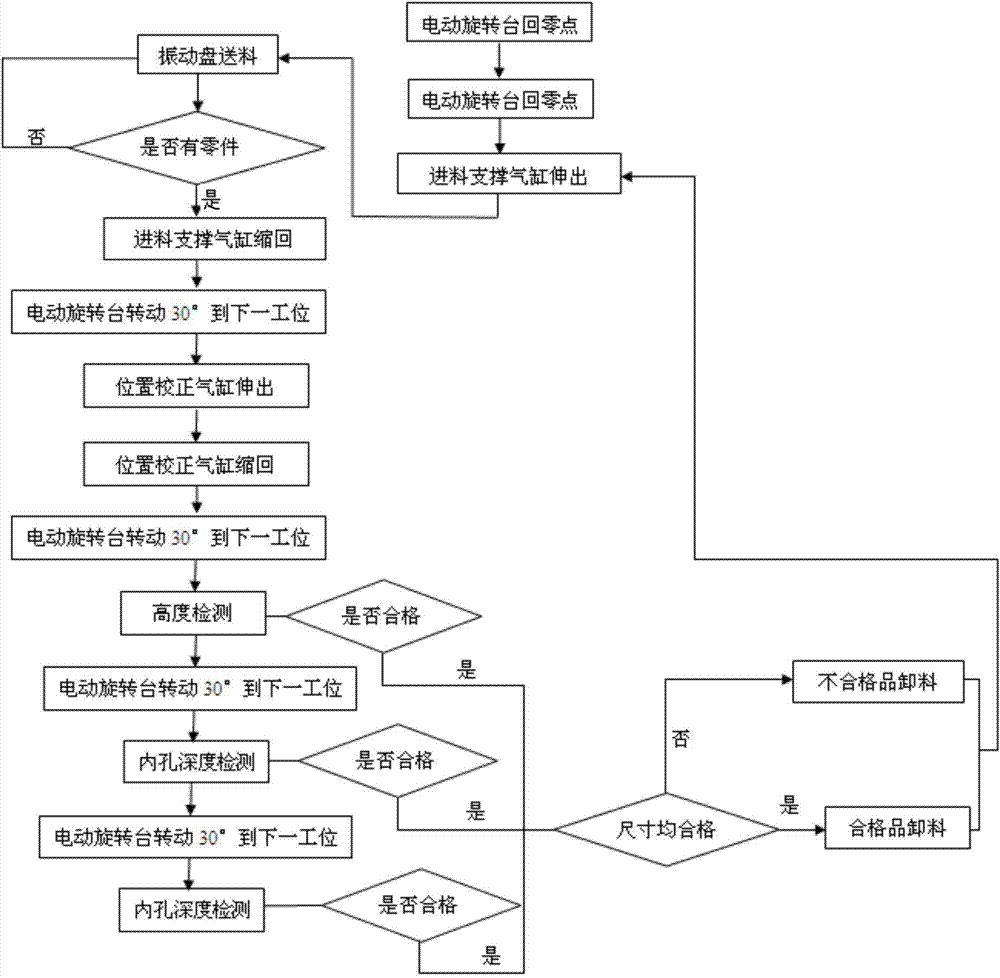

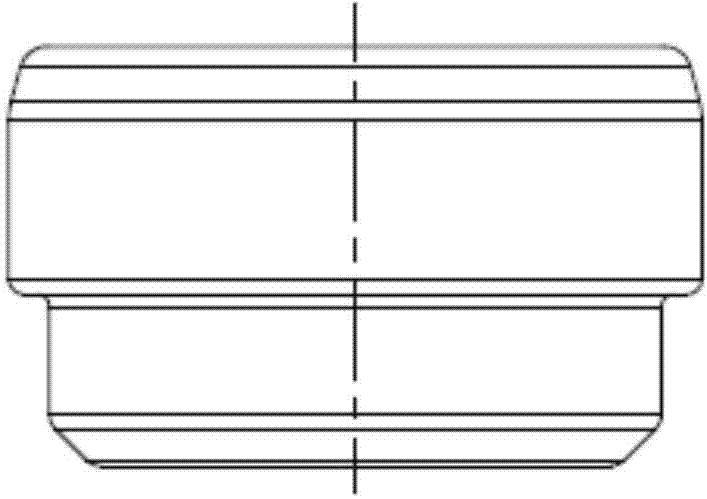

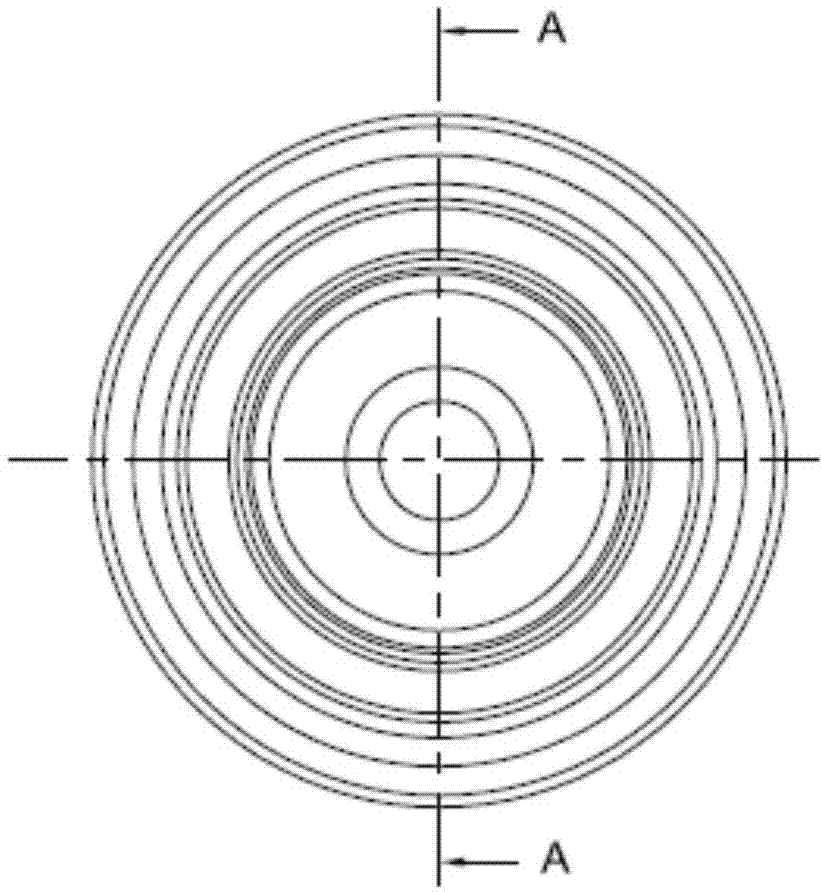

Full-automatic detection device and method for height and inner hole depth of pilot valve seat

A detection equipment and deep detection technology, applied in the field of precision detection, can solve the problems of labor cost, detection error and low efficiency, and achieve the effect of reducing labor, high efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] see Figure 4-6 , the invention discloses a fully automatic detection device for pilot valve seat height and inner hole depth. As shown in the figure: it includes a spiral vibrating plate 1, and the outlet of the spiral vibrating plate 1 extends to the feeding position of the electric rotary table 12 through the horizontal track 13, and the feeding position of the electric rotary table 12 is provided with a feeding support Cylinder 11 and feed optical fiber sensor 2, also have position correction cylinder 3 near the feeding position of this electric rotary table 12, the detection station place of this electric rotary table 12 is provided with height detector 4 and inner hole depth detector 5, The discharge station of the electric rotary table 12 is provided with a non-conforming product unloading mechanism 7, a non-conforming product receiving mechanism 6, a qualified product unloading mechanism 9, and a qualified product receiving mechanism 8. A discharge optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com