Method for correcting automobile headlamp detecting light bundle shining direction deviation

A technology for automobile headlights and irradiation direction, which is applied in the field of correction of the deviation of the beam irradiation direction of automobile headlight detection beams, can solve problems such as poor repeatability and inaccurate measurement data, and achieves low cost, high precision, and improved measurement accuracy and reliability. repetitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

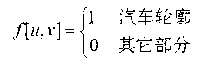

Method used

Image

Examples

Embodiment Construction

[0048] refer to figure 1 Construct the automobile headlamp light beam irradiation direction correction system, in the embodiment of the present invention, a CMOS digital camera is set above the inspected automobile, about 3 meters above the ground, the image collected is transmitted to the industrial computer through the USB interface, and the front The detection data of the lighting tester is corrected from time to time. Firstly, sixteen target images are collected, the position of the first target is strictly aligned with the detection site, the camera is calibrated, and the rotation matrix of the external parameters of the camera is obtained through computer program analysis, and then the deflection angle of the image to the detection site is obtained. Then, the car is parked at the detection position, the top view image of the car is taken, and the deflection angle of the longitudinal axis of the car to the image coordinates is obtained by analyzing the computer image pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com