Multi-station conveying shooting mechanism for automatic detection of soft-magnetic magnetic core

An automatic detection, multi-station technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of inaccurate placement of magnetic cores, affecting imaging quality, low detection efficiency, etc., to achieve simple structure, high detection efficiency, and error-free The effect of low detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

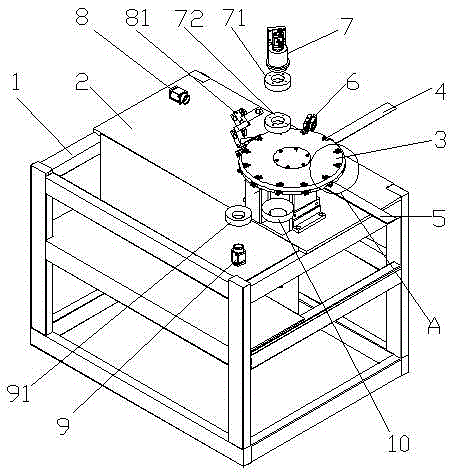

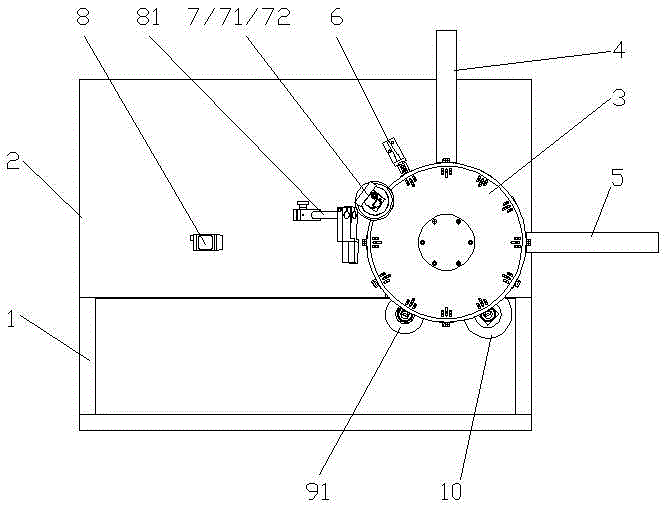

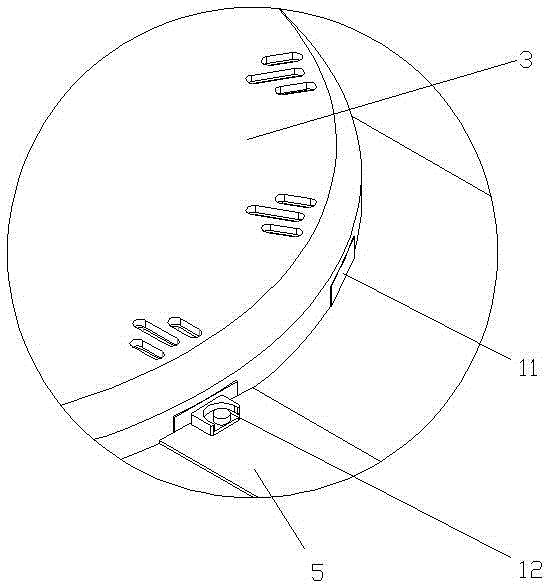

[0022] like Figure 1 to Figure 3 Shown is a multi-station transmission camera mechanism for automatic detection of soft magnetic cores, including frame 1, installation platform 2, turntable 3, feed conveyor belt 4, discharge conveyor belt 5, workpiece calibration device 6, camera A7, light source AA71, light source AB72, camera B8, light source B81, camera C9, light source C91, camera D and light source D10. The installation platform 2 is arranged on the frame 1, and the turntable 3 is arranged on the installation platform 2. The turntable 3 is driven by the turntable drive mechanism and can rotate at a constant speed and intermittently. The side of the turntable 3 is equally divided into 12 stations 11; the feed conveyor belt 4 is equipped with adjustable guide rails and is driven by a stepping motor; the discharge conveyor belt 5 is driven by a servo motor; the workpiece calibration device 6 is a pneumatic claw. According to the rotation direction of the turntable, the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com