Patents

Literature

33results about How to "Realize automatic feeding and discharging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

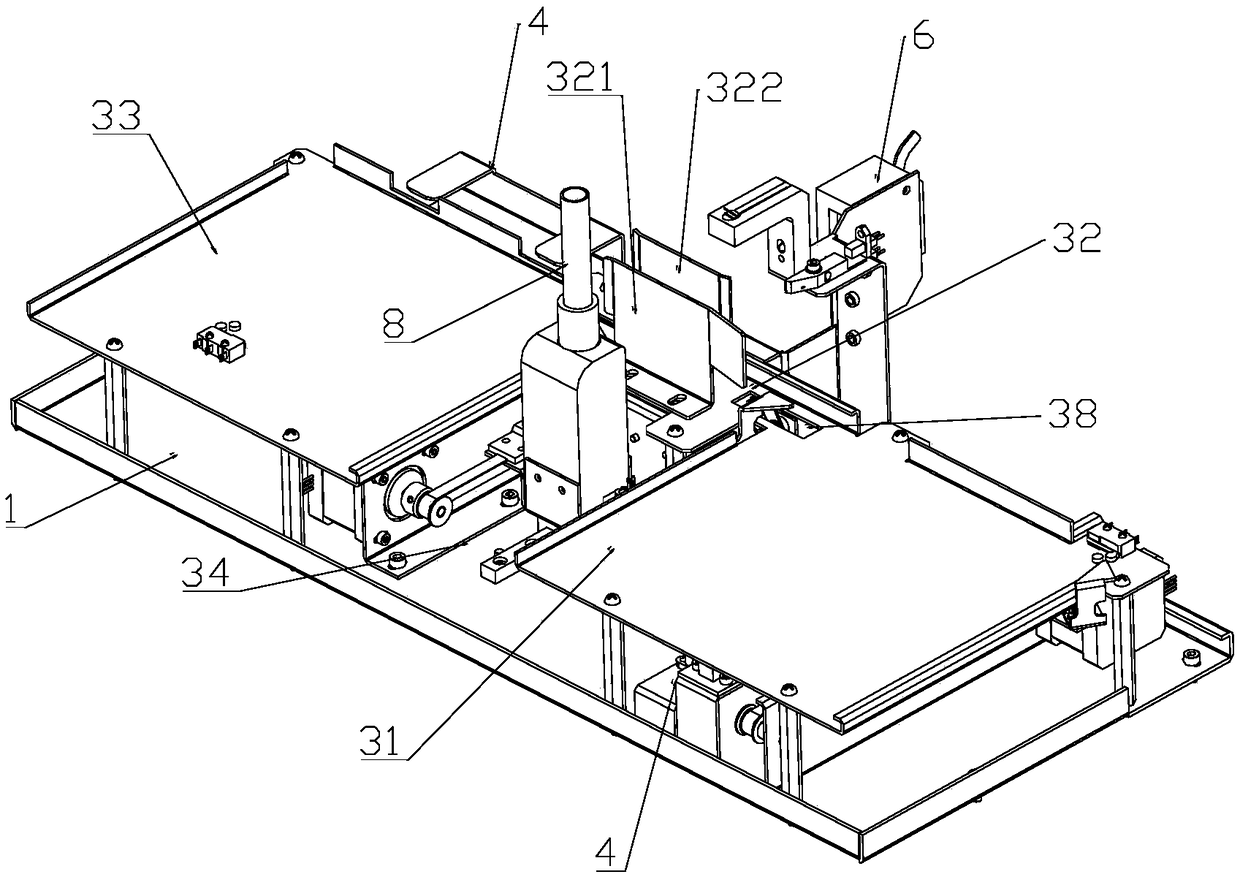

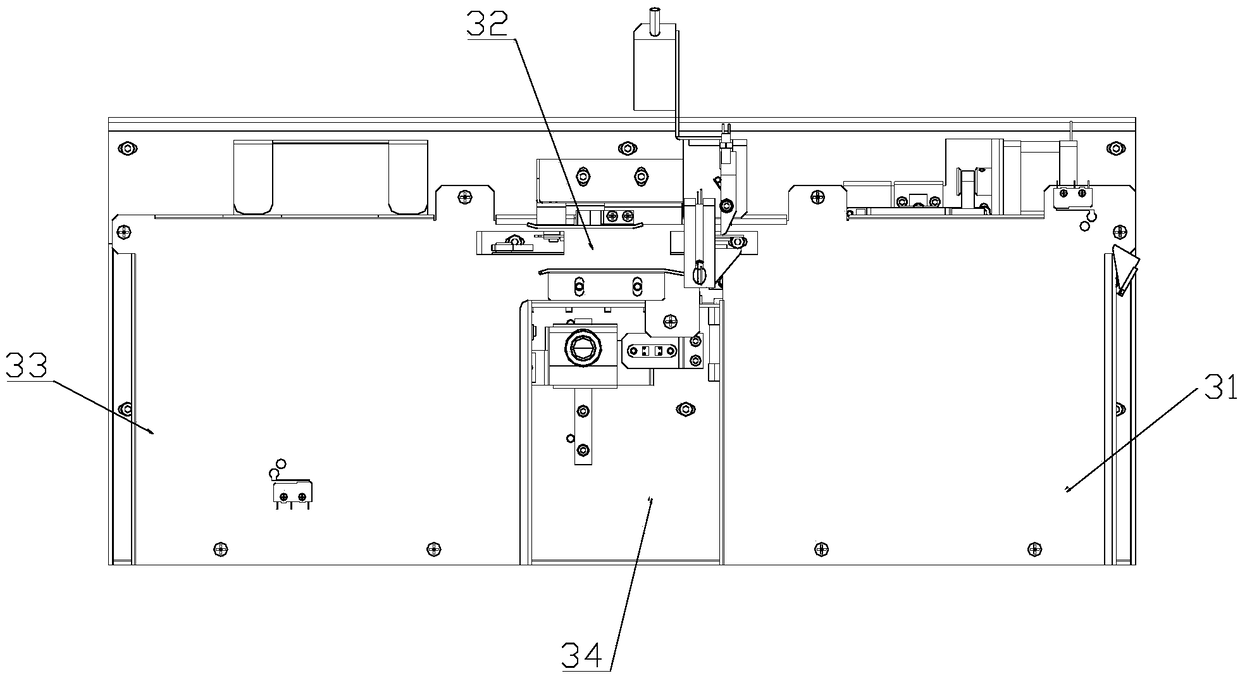

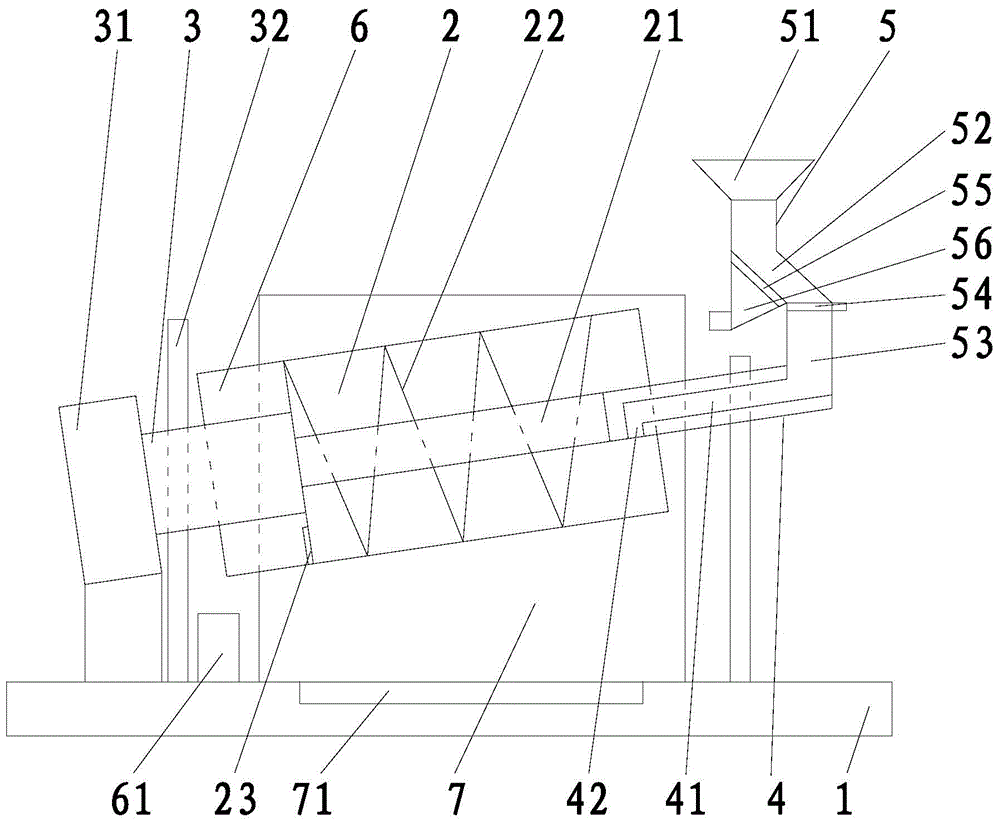

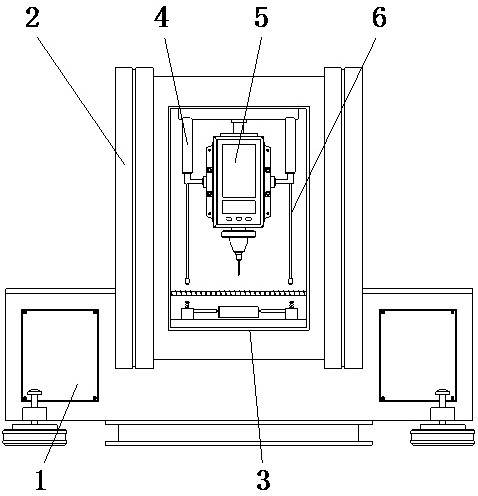

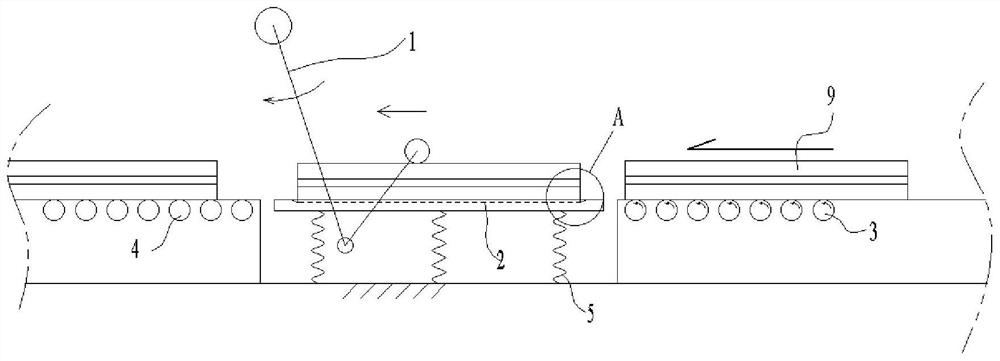

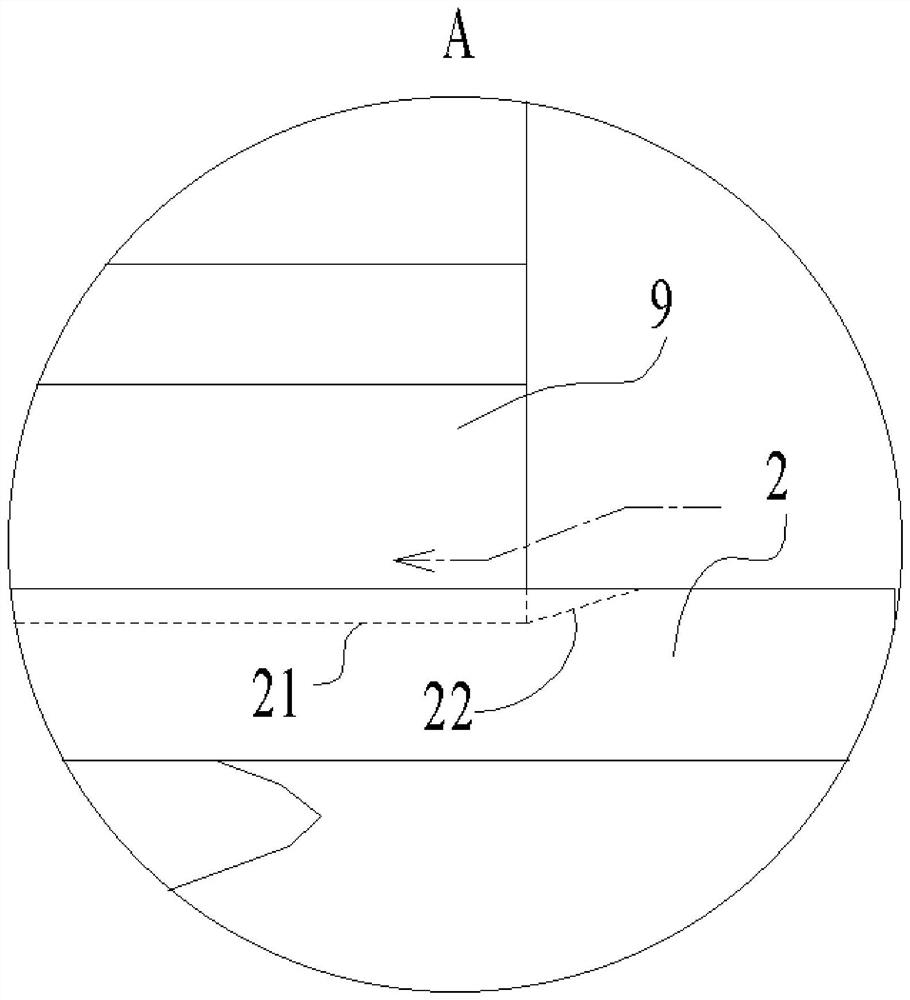

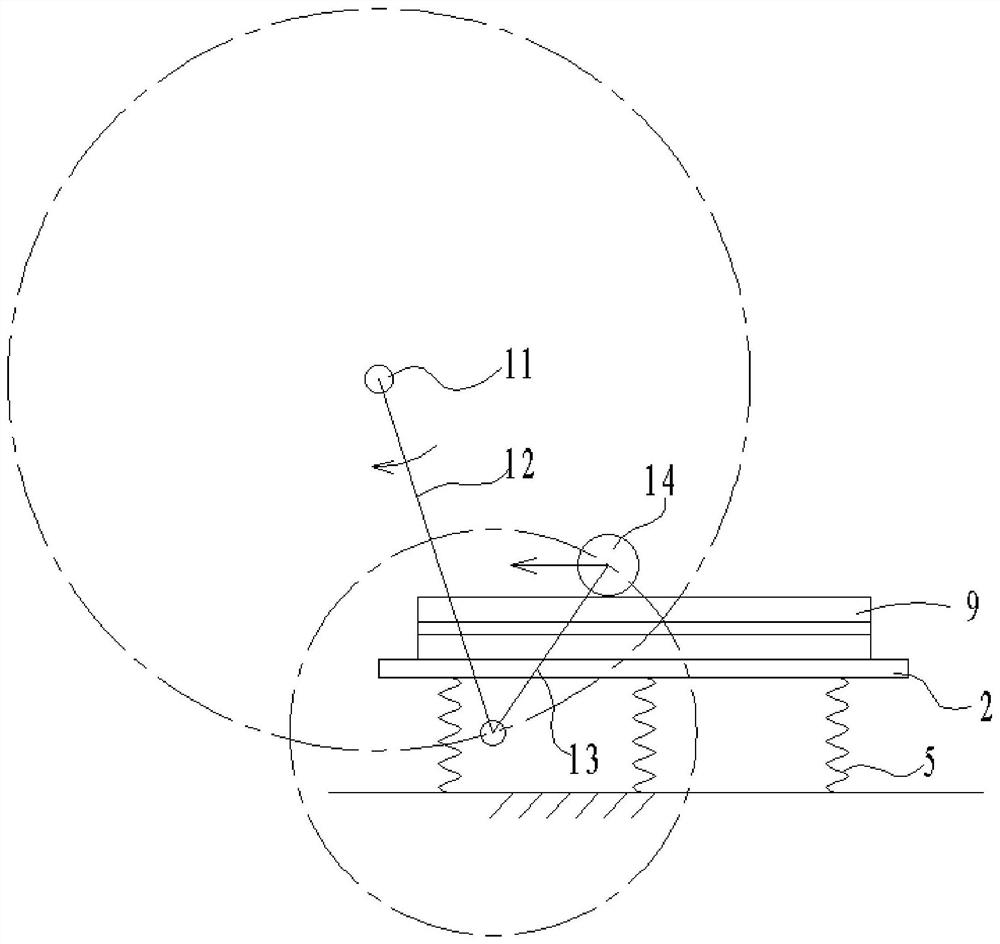

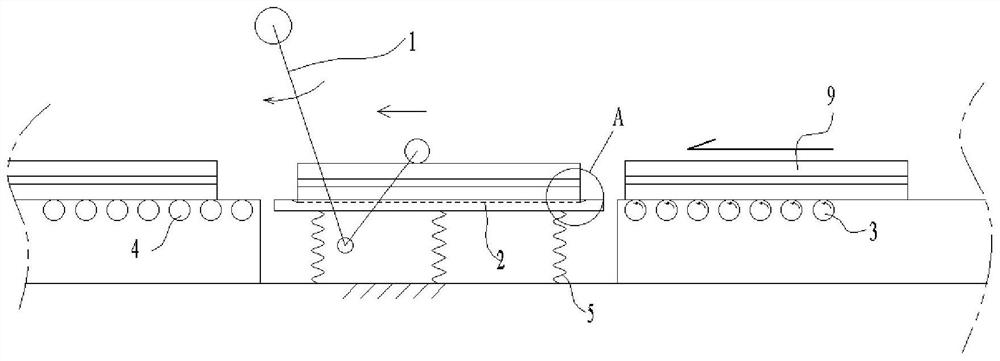

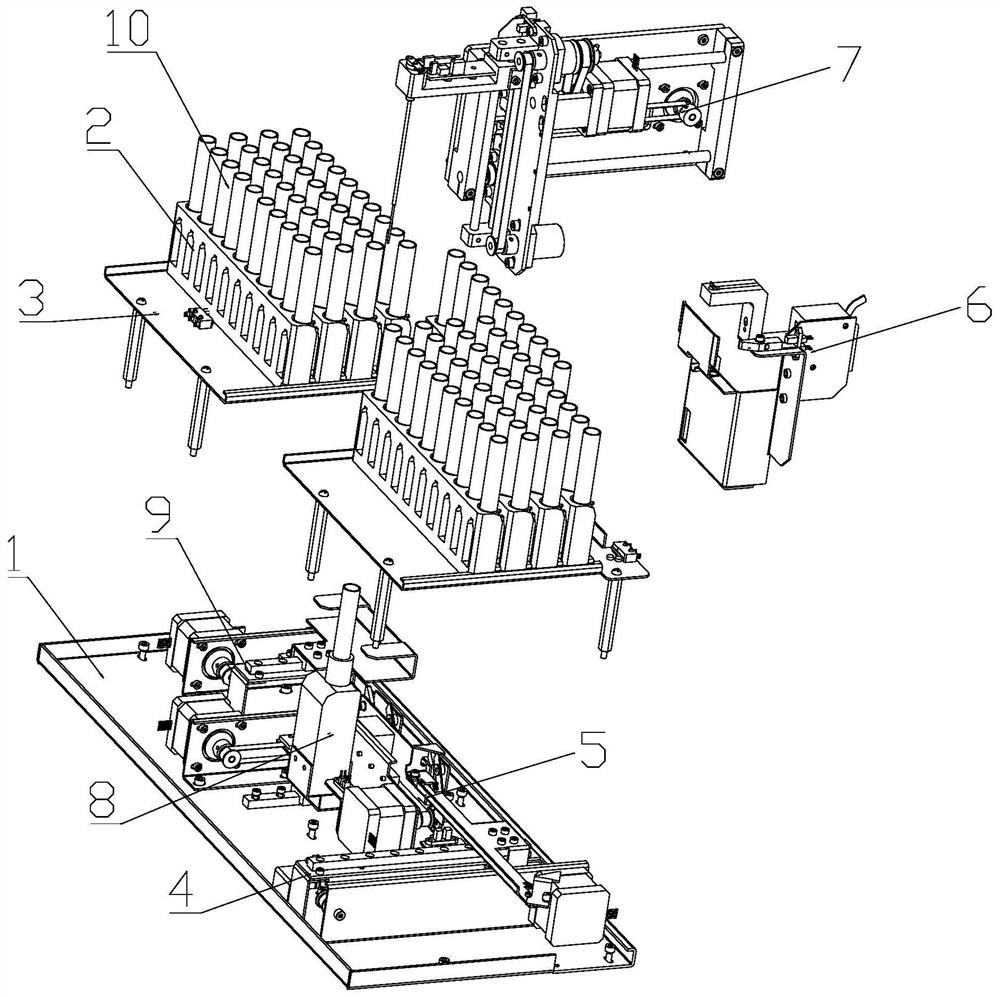

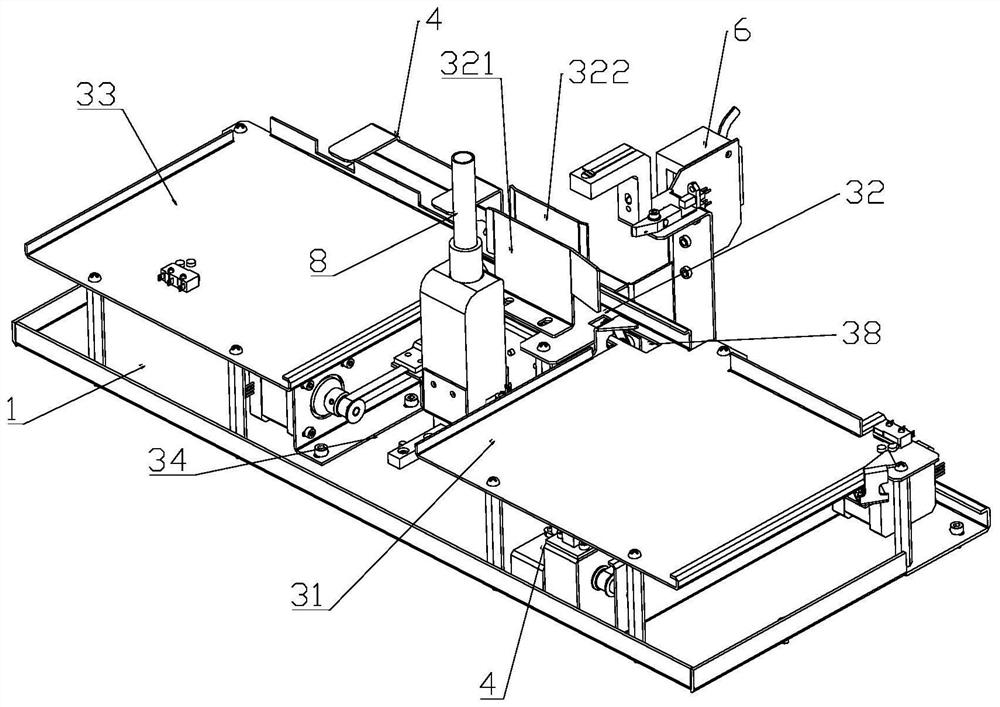

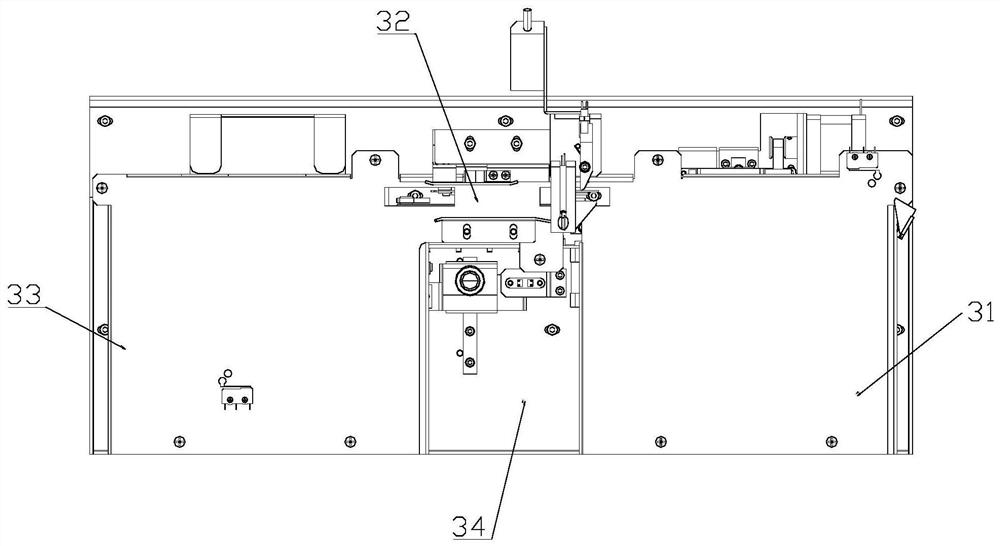

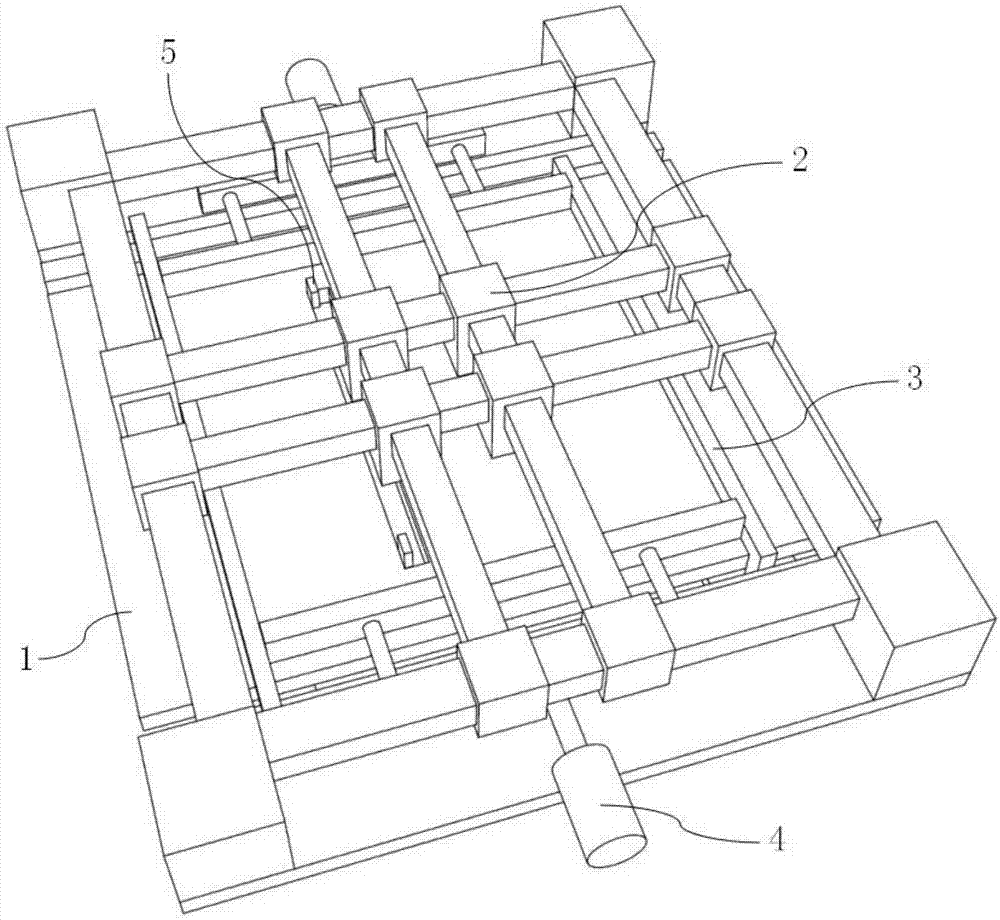

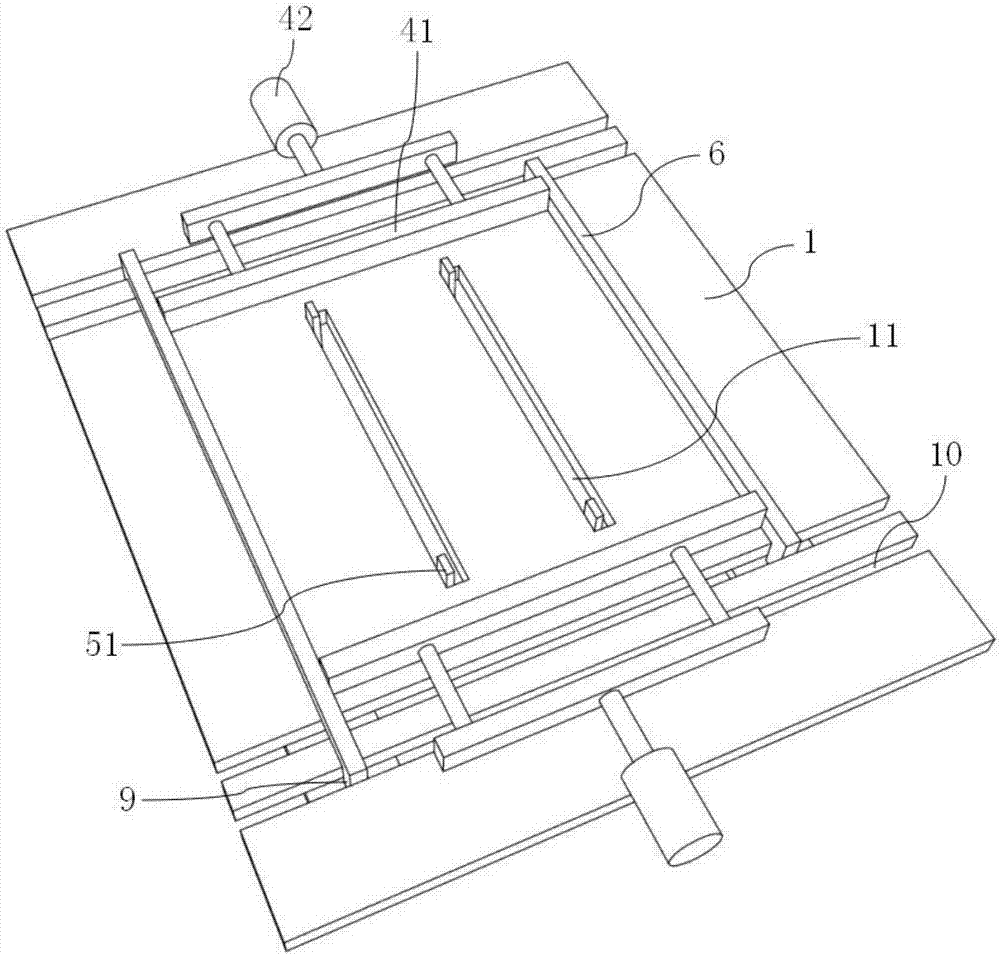

Display screen detection equipment

PendingCN107884342ARealize automatic feeding and dischargingEfficient detectionMaterial analysis by optical meansComputer scienceComputer engineering

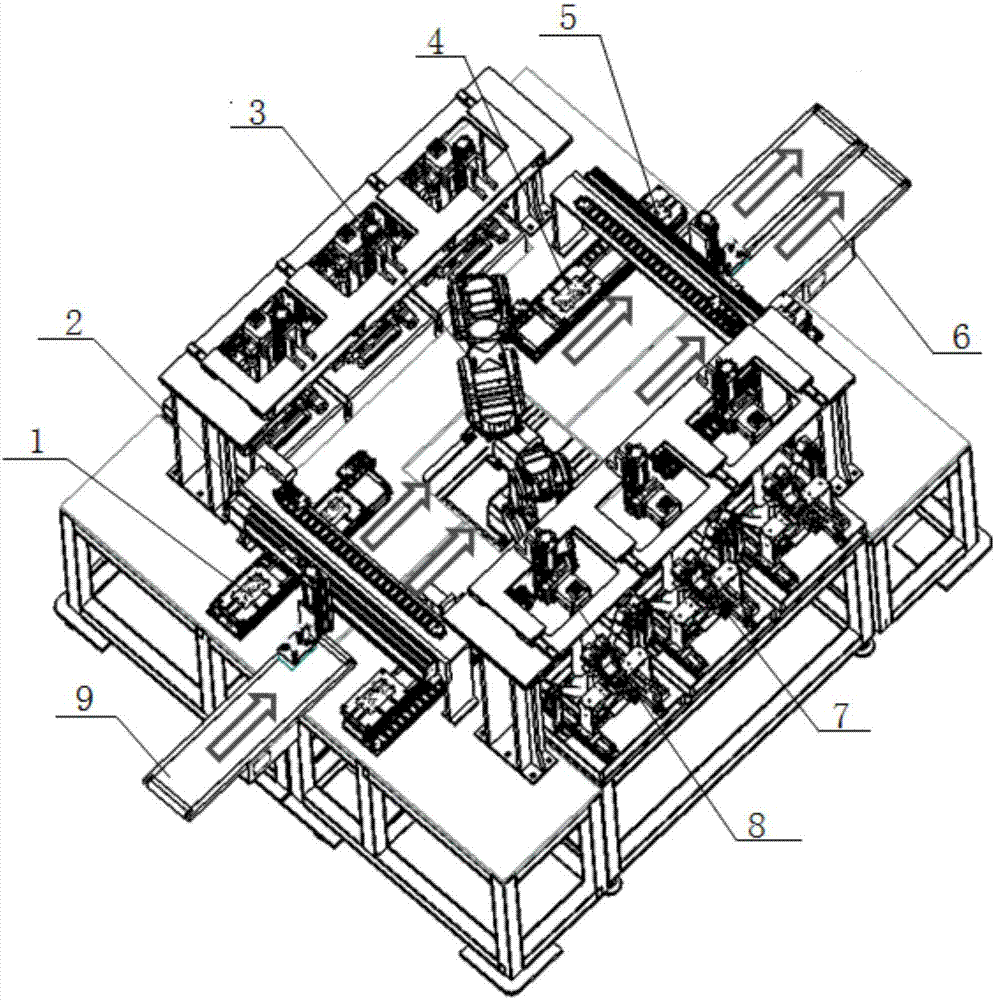

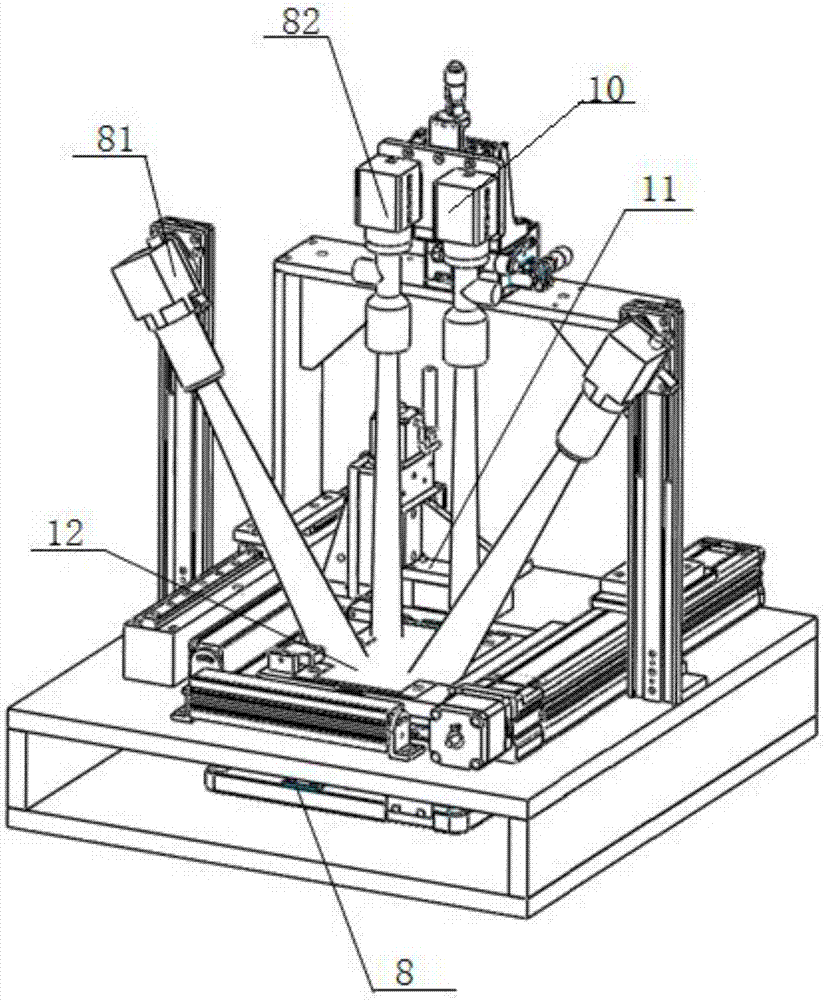

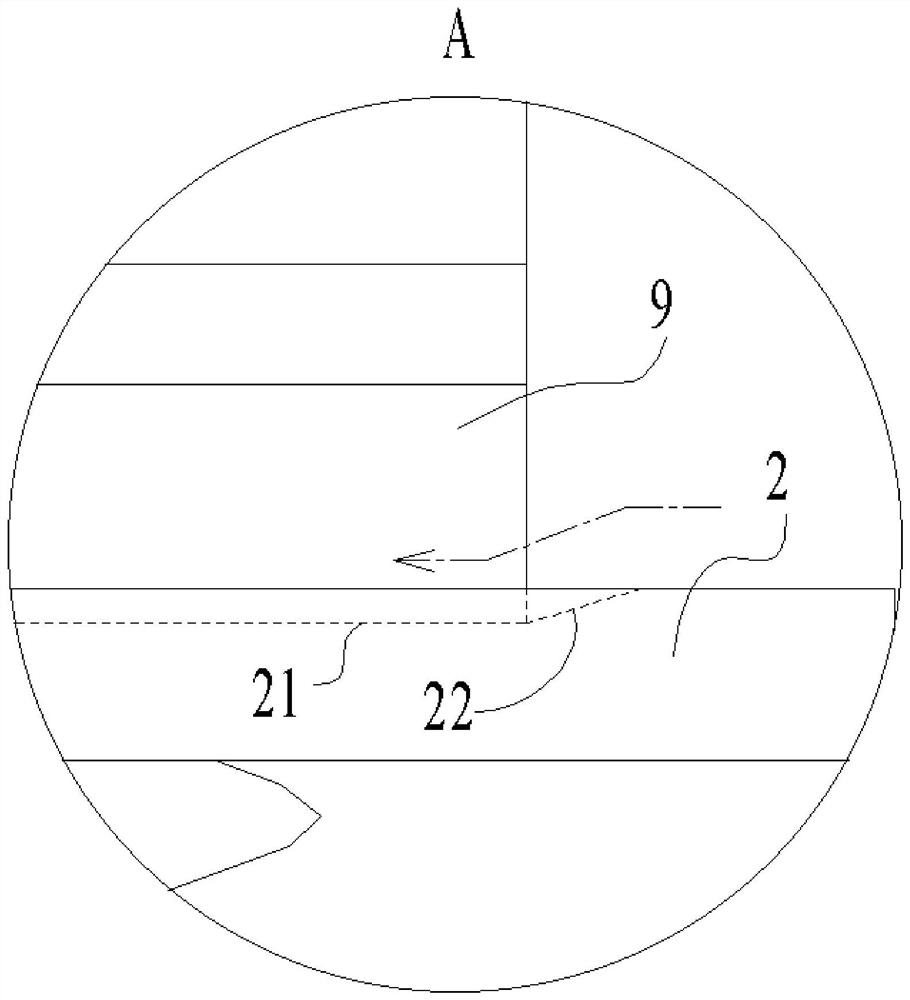

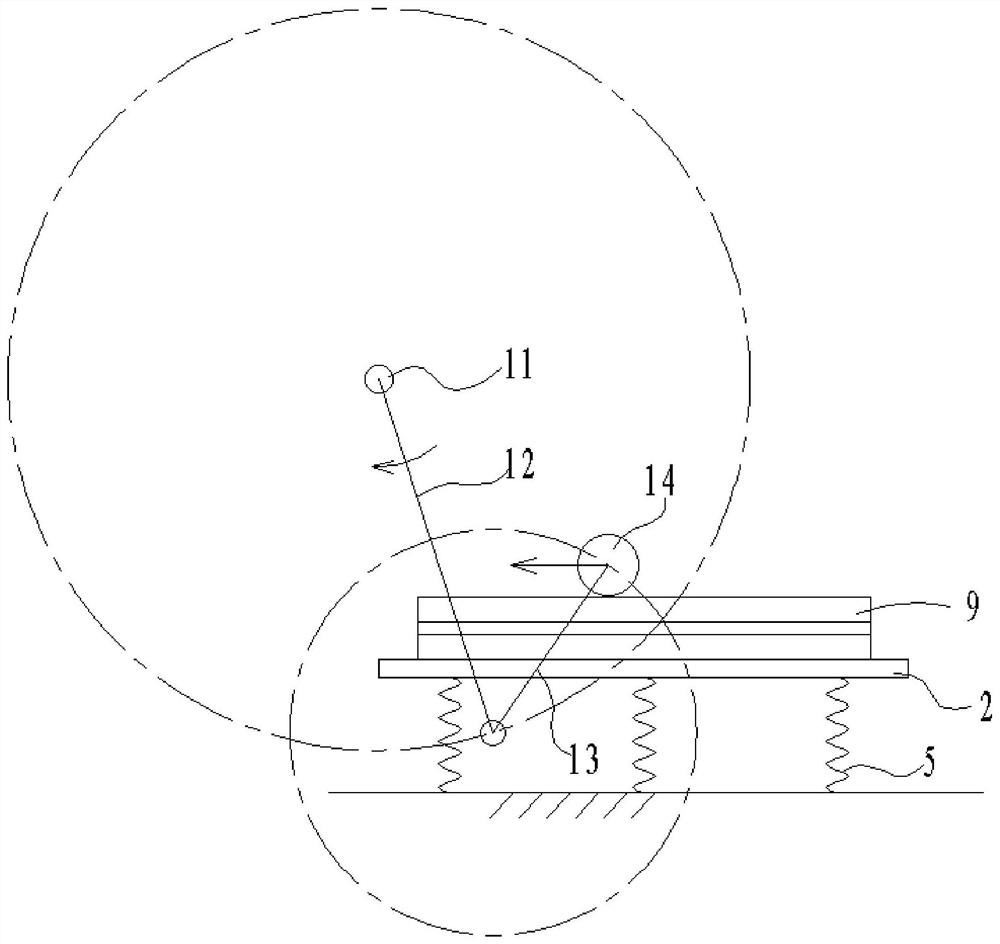

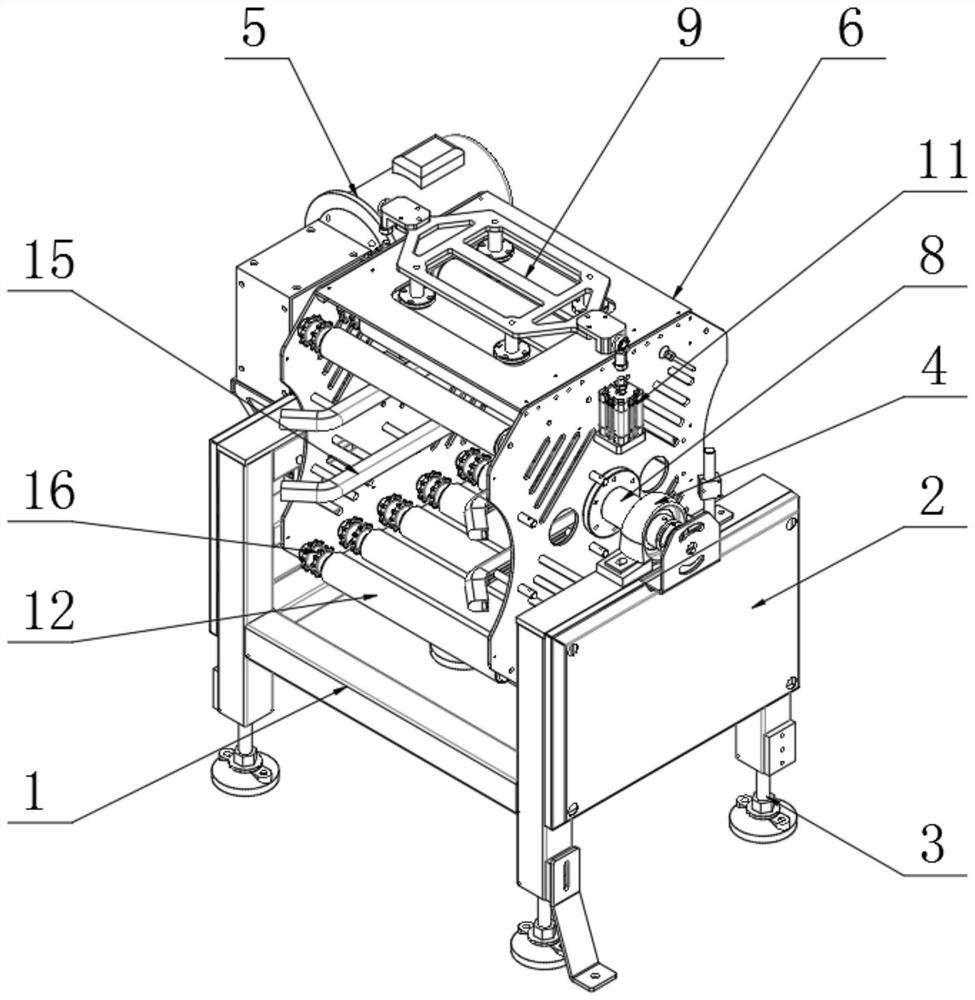

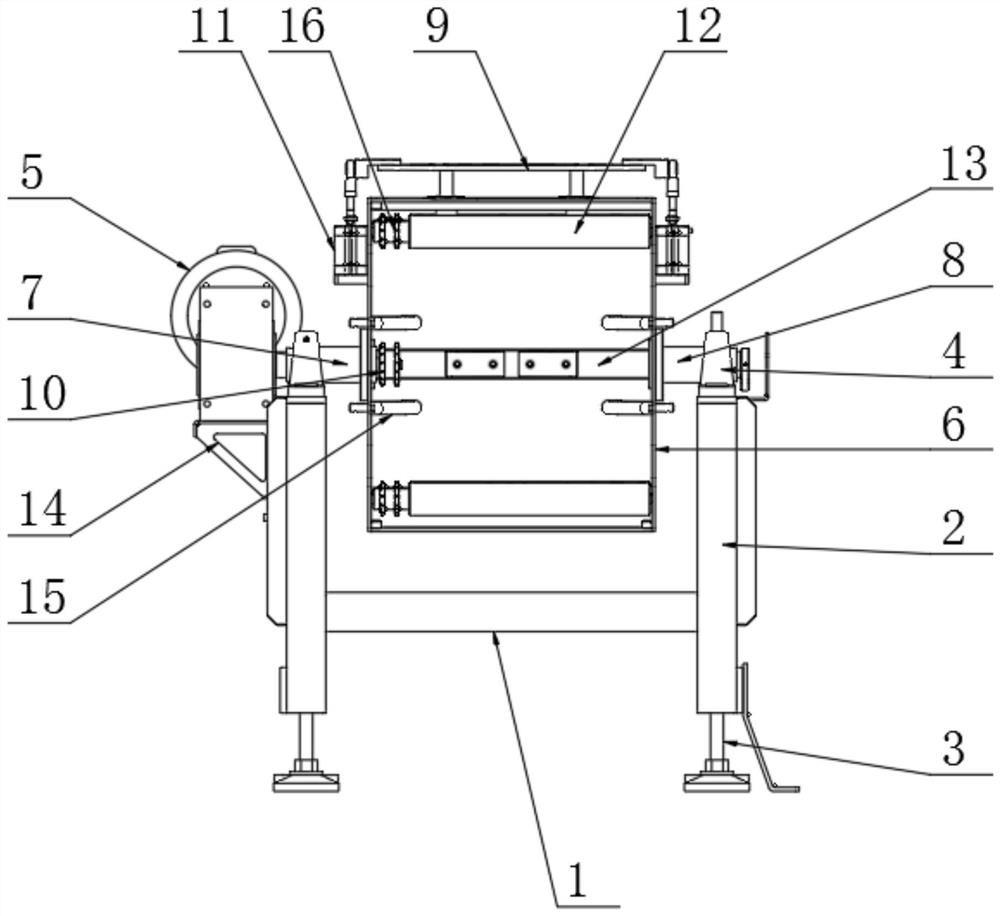

The invention discloses display screen detection equipment which comprises a controller, an automatic alignment fixture, a locating camera, a detection assembly and a manipulator, wherein the automatic alignment fixture is capable of adjusting a display screen placed on the fixture to a target position according to received adjustment parameters; the locating camera is capable of shooting the display screen placed on the automatic alignment fixture, the controller can calculate the offset direction, distance and angle of the display screen according to the shot image of the locating camera, and the offset direction, distance and angle of the display screen are taken as the adjustment parameters to be transmitted to the automatic alignment fixture; the detection assembly is capable of shooting the display screen positioned at the target position on the automatic alignment fixture, and the controller can analyze the defects of the display screen and generate detection results according to the shot image of the detection assembly; and the manipulator is capable of conveying a to-be-detected display screen onto the automatic alignment fixture from a take-out position and conveying thedetected display screen on the automatic alignment fixture to a discharging position. The display screen detection equipment can effectively solve the problems that the display screen detection efficiency is low and the degree of automation is low.

Owner:DONGGUAN SUMIDA AUTOMATION CO LTD

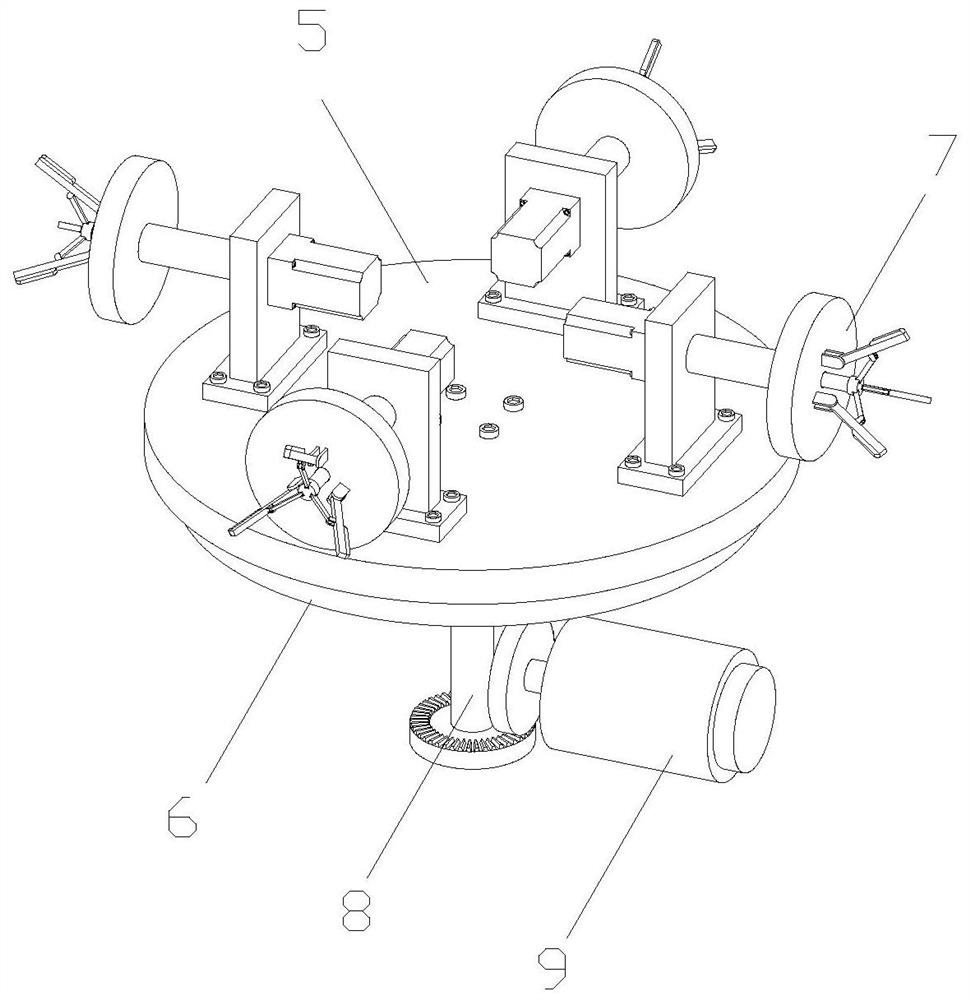

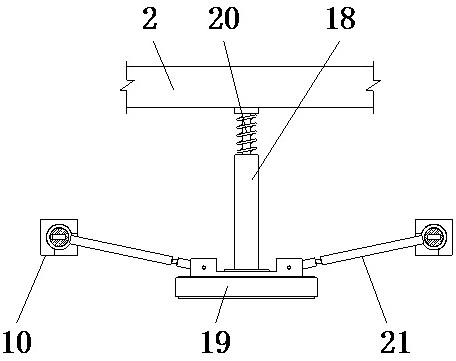

Safe moving mechanism based on paint spraying device

InactiveCN111760699APrevent fallingAdjustable spacingSpraying apparatusElectric machineTransmission belt

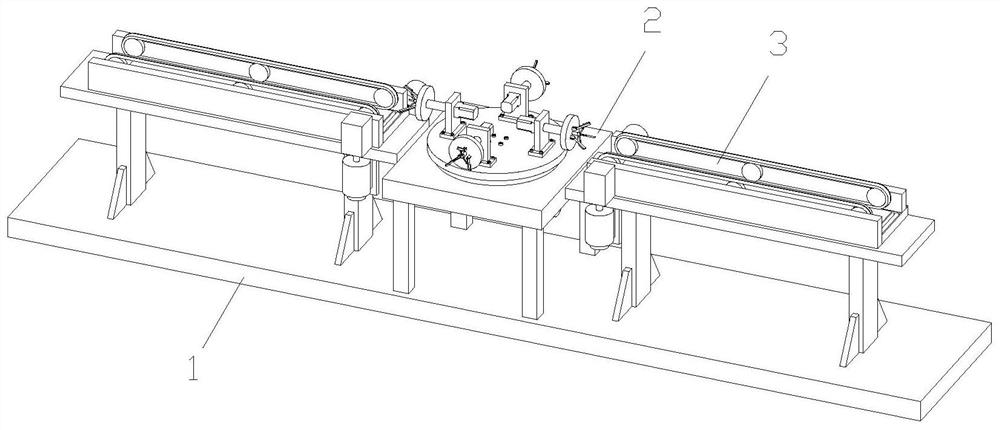

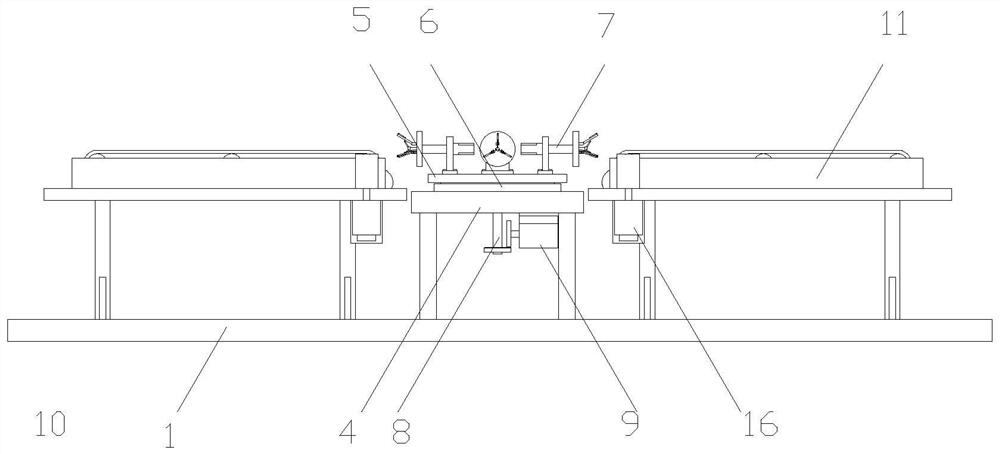

The invention discloses a safe moving mechanism based on a paint spraying device. The mechanism includes a base, a rotating mechanism is fixedly mounted on the middle of the base, horizontal moving mechanisms are symmetrically arranged on two sides of the rotating mechanism, the rotating mechanism includes a first mounting frame, a rotating working table, a clamping assembly, a rotating main shaft, and a first motor, and the horizontal moving mechanism includes a second mounting frame, a fixing seat, a moving seat, a sliding rail, a guide wheel, a transmission belt, and a second motor. According to the safe moving mechanism, the first motor drives the rotating main shaft to rotate, the rotating main shaft drives the rotating working table to rotate, so that pipe-shaped work pieces in the clamping assembly rotate to the direction perpendicular to the horizontal moving mechanism to carry out spraying operation, the work pieces are taken out through the rotating working table after spraying is finished, the automatic feeding and discharging of the work pieces can be achieved during spraying, and the efficiency of work piece spraying is improved.

Owner:铜陵长江金刚石工具股份有限公司

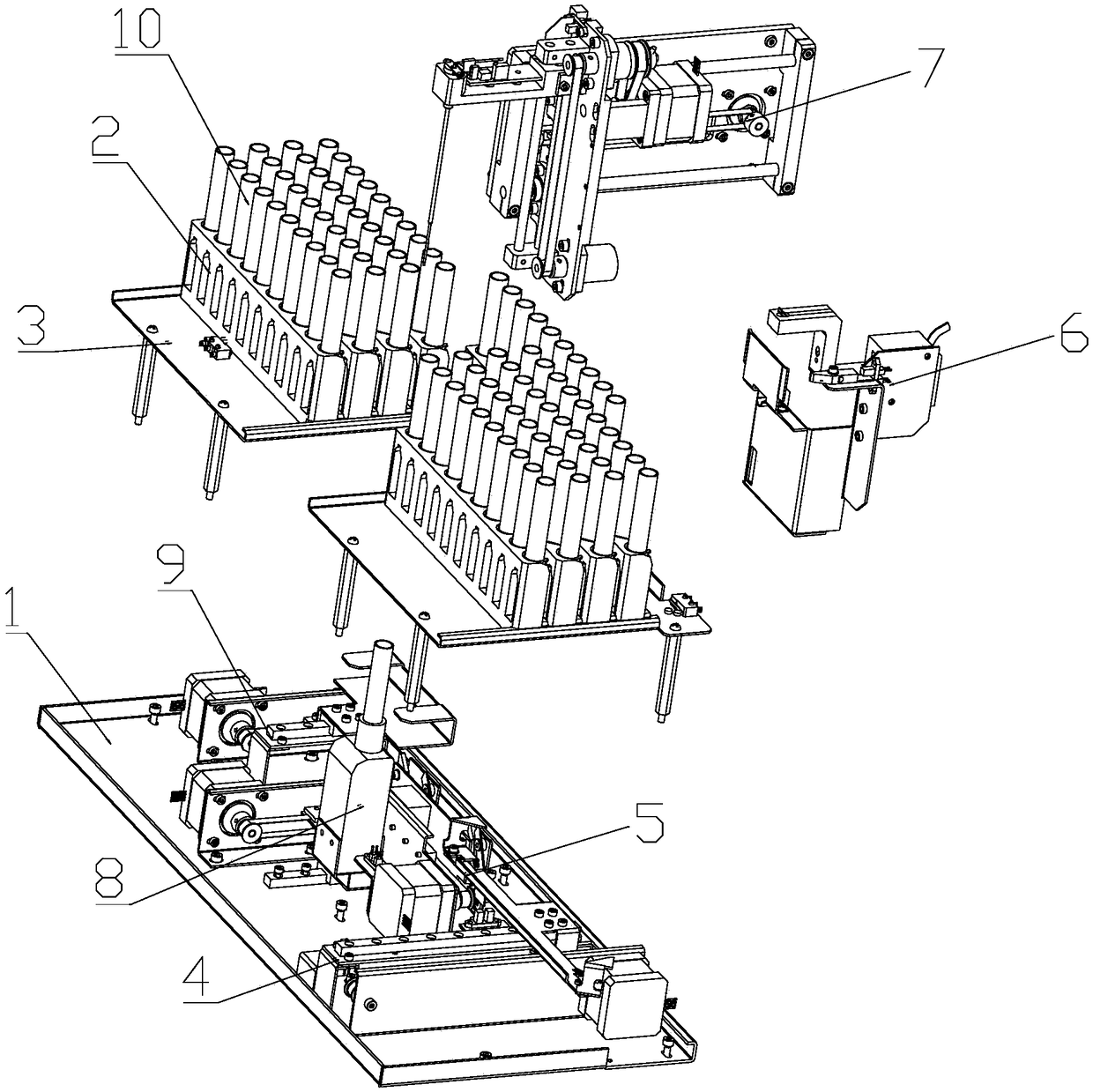

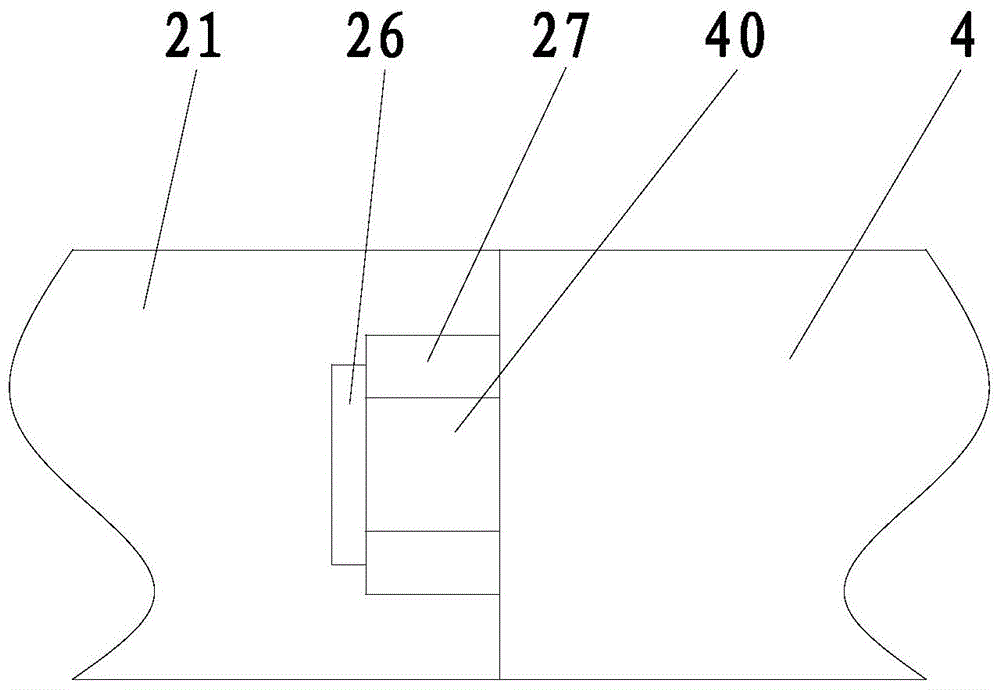

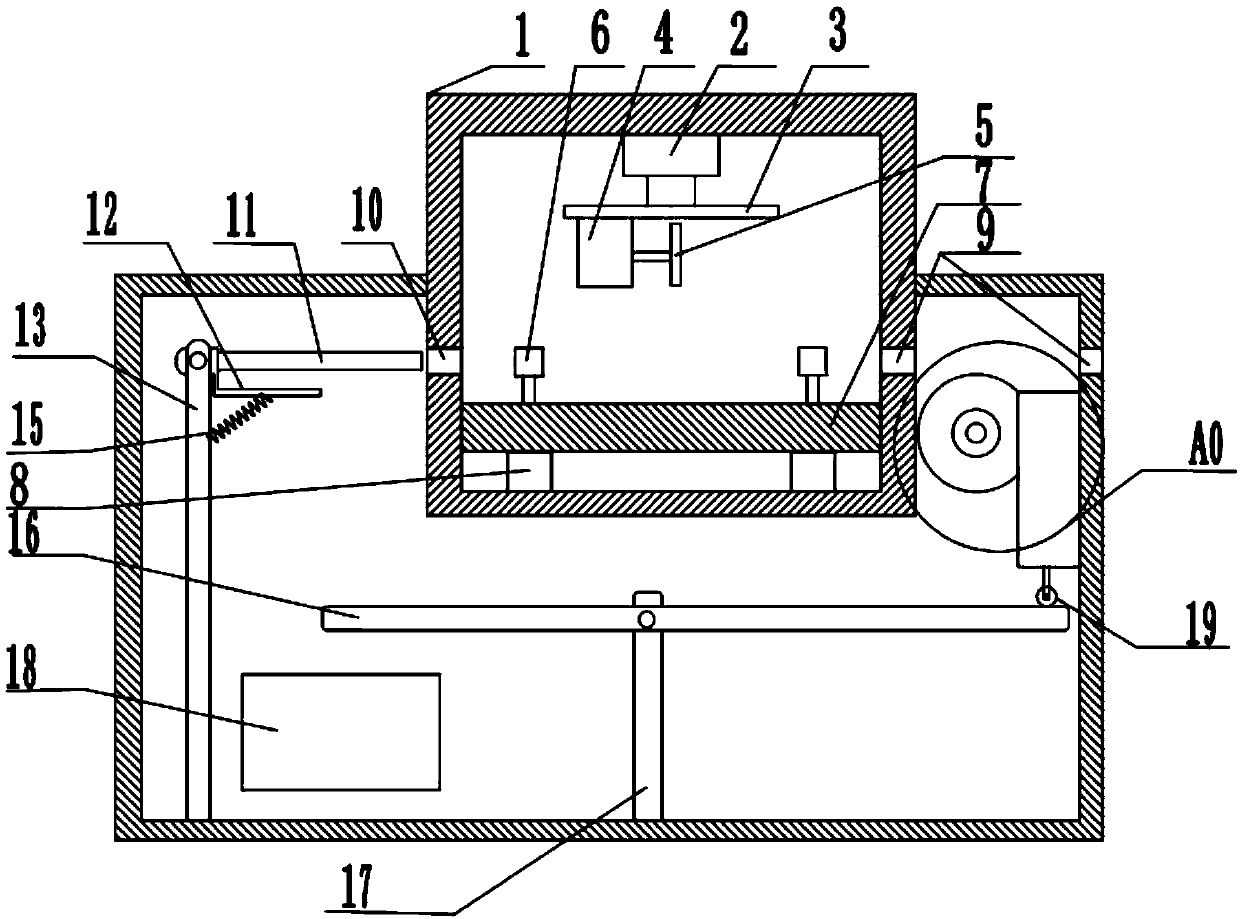

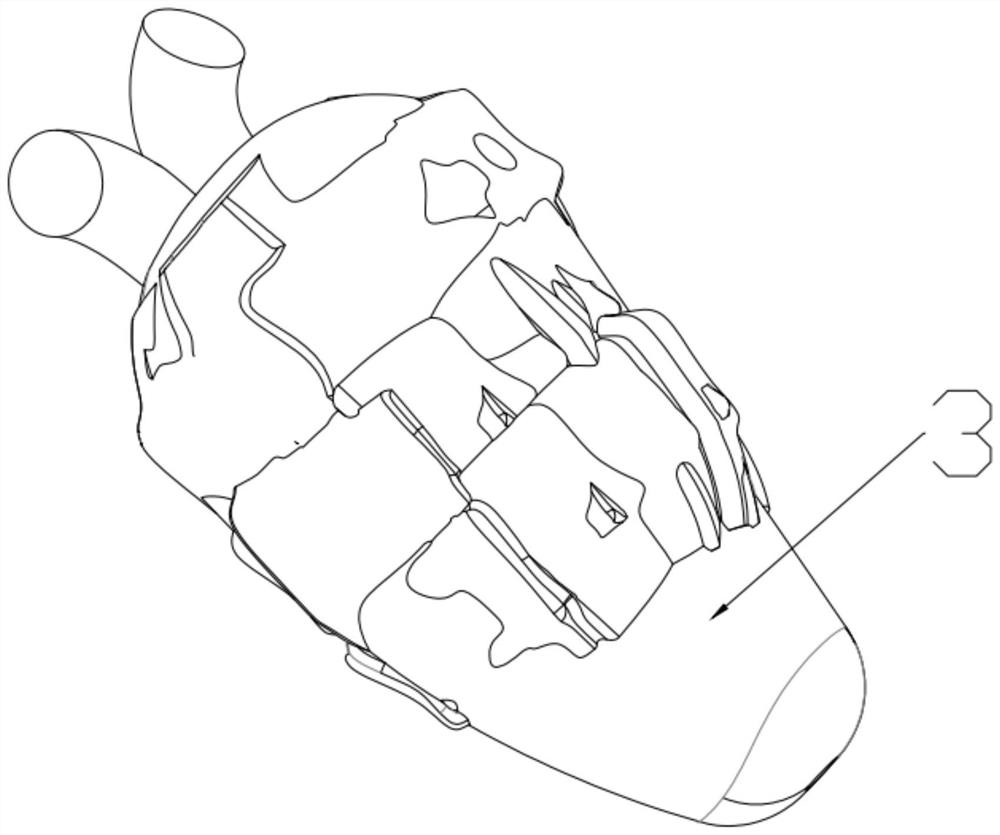

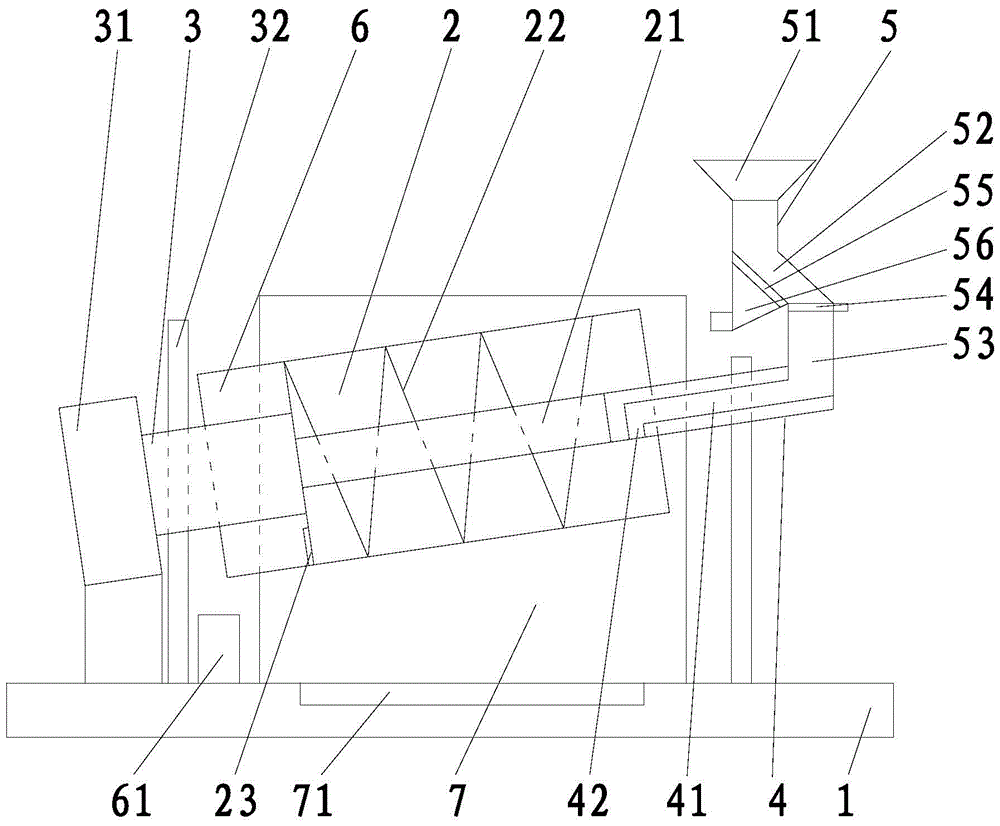

Biochemical detector

ActiveCN108717113ARealize automatic feeding and dischargingQuick checkBiological testingFeed driveBiochemical engineering

The invention relates to medical biological detection equipment and in particular relates to a biochemical detector which comprises a rack, a bottom plate, a test tube rack, a tube rack logistic plate, a sample feeding driving device, a positioning driving device, an optical detection device, a sampling device, a cleaning device and a sample discharge driving device, wherein the bottom plate and the sampling device are fixedly arranged on the rack; the tube rack logistic plate is arranged above the bottom plate through a connecting plate; the sample feeding driving device, the positioning driving device and the sample discharge driving device are fixedly arranged on the bottom plate. By adopting the biochemical detector, automatic material feeding and discharge of a test tube rack are achieved, samples can be automatically conveyed to a detection station to be detected, automatic, rapid and convenient detection is achieved, and large-scale detection requirements can be met.

Owner:山东华航医学科技有限公司

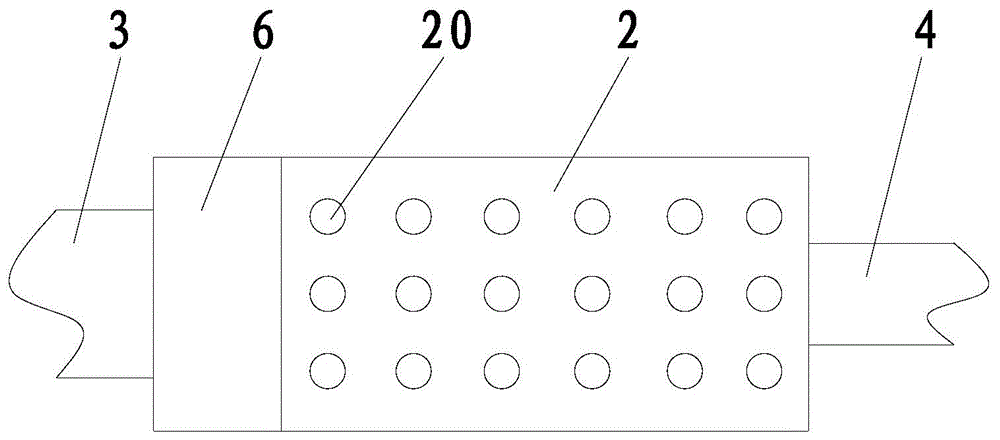

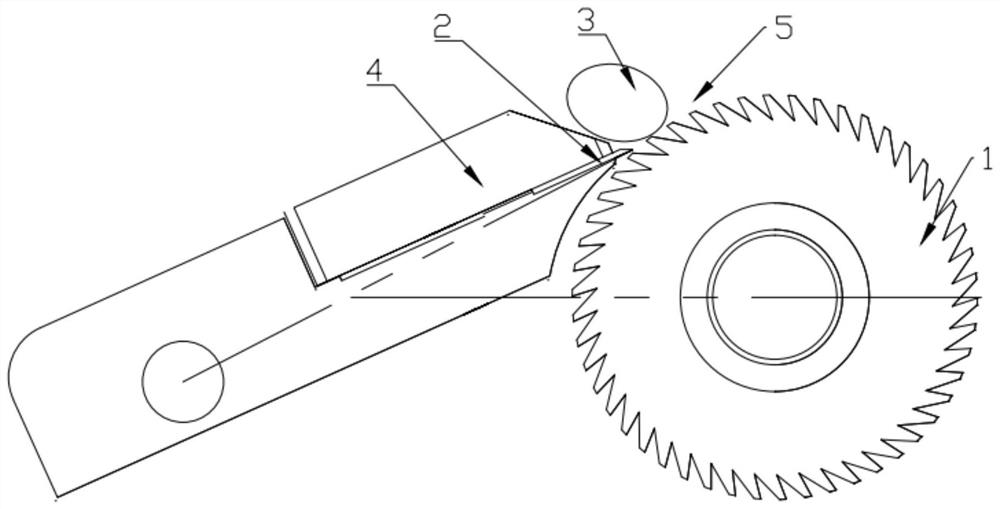

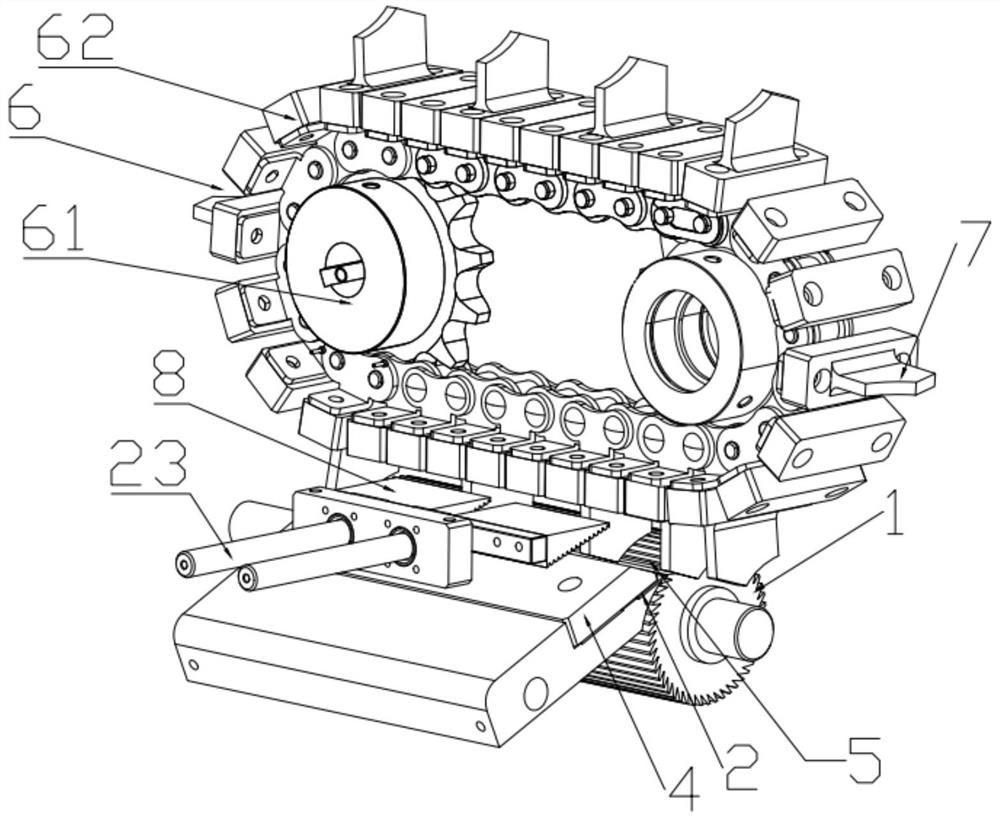

Automatic blanking discharging de-oiling machine

ActiveCN104399599ARealize automatic feeding and dischargingExtension of timeRotary centrifugesEngineeringMechanical engineering

The invention discloses an automatic blanking discharging de-oiling machine which comprises a rotating drum, a rotating shaft, a power device, a supporting shaft, a feeding hopper and a frame, wherein the rotating drum is connected with the rotating shaft; the rotating shaft is connected with the power device; the power device is fixed on the frame; a plurality of oil draining holes are uniformly distributed in a drum wall of the rotating drum; a central pillar is arranged in the rotating drum; a spiral baffle is arranged on the central pillar; a blanking channel is arranged in the supporting shaft; a blanking hole is arranged in a side wall of an end part of the blanking channel in the rotating drum; the interior of the rotating drum and the blanking channel are communicated with each other by the blanking hole; the other end of the blanking channel is connected with the feeding hopper; a discharging door is arranged on the end part of one side, which is connected with the rotating shaft, of the rotating drum; a protecting fence is arranged on the side, connected with the rotating shaft, of the rotating drum; an oil baffle cover is arranged on the outer periphery of the rotating drum; an oil collecting slot is arranged in the frame under the oil baffle cover. According to the automatic blanking discharging de-oiling machine, the blanking channel and the feeding hopper are connected with each other and the discharging door is arranged on the rotating drum, so that the automatic blanking and discharging of the de-oiling machine are realized, the de-oiling process is continuously performed and the de-oiling efficiency is increased.

Owner:ZHEJIANG RONNIE PRECISION MACHINE

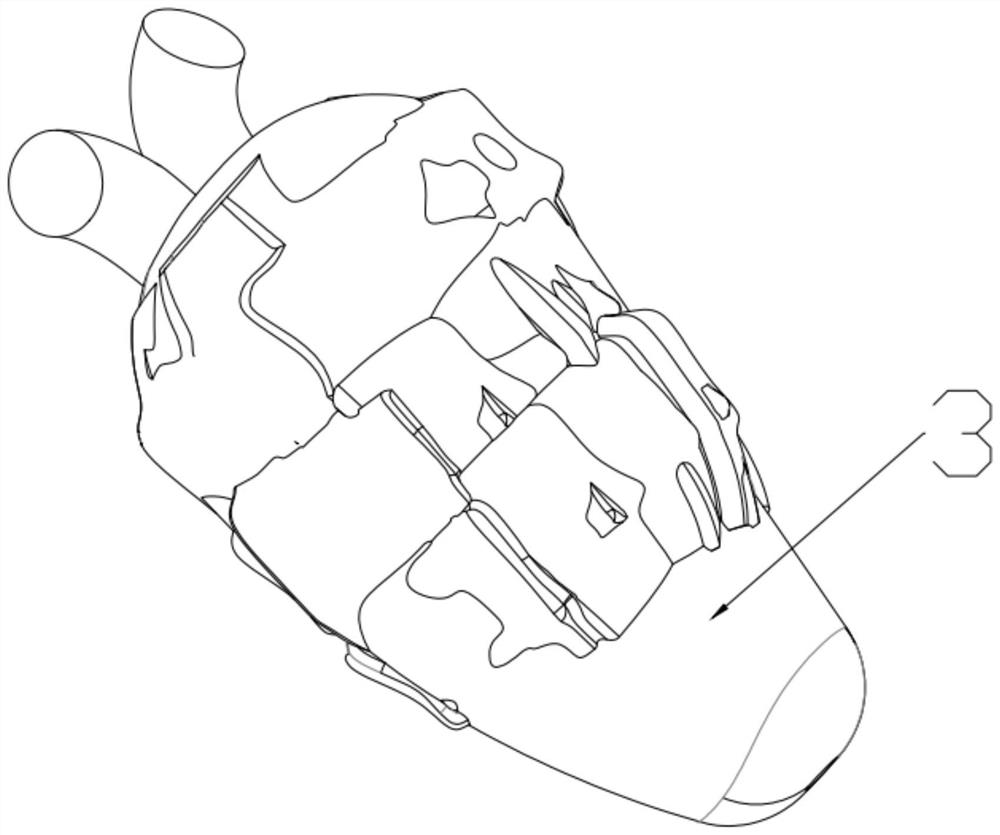

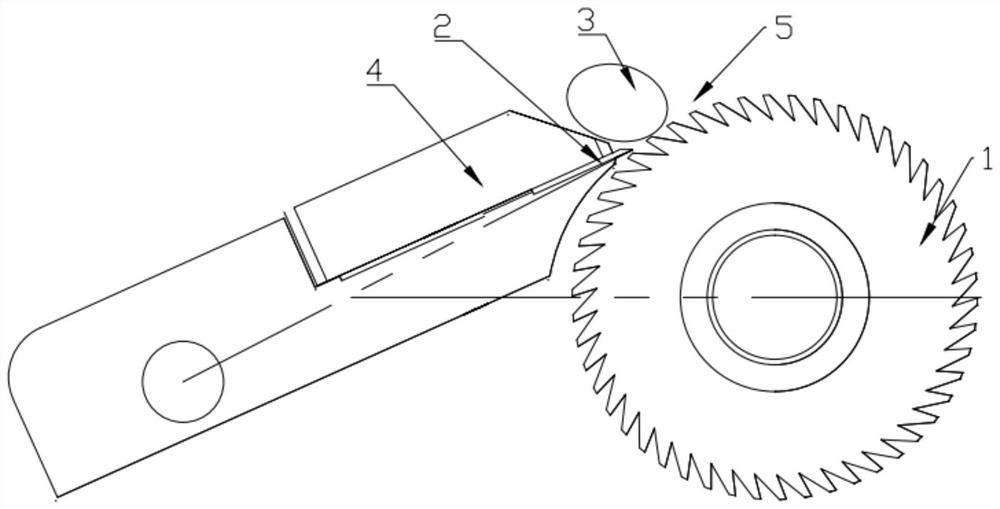

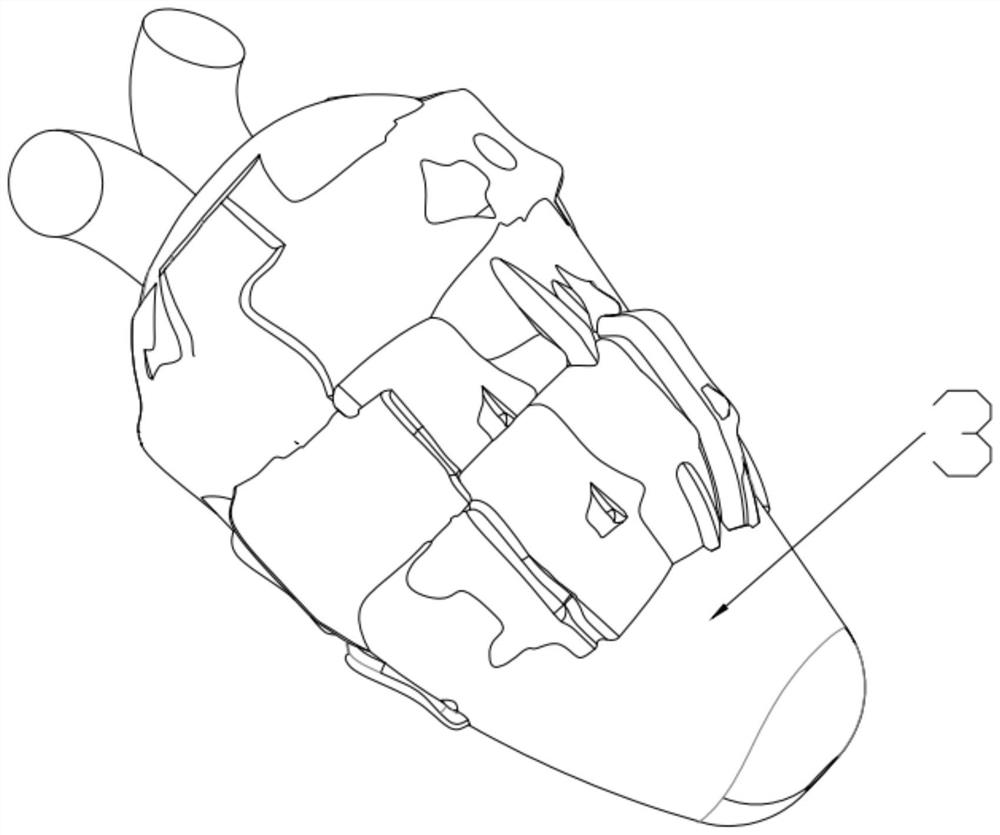

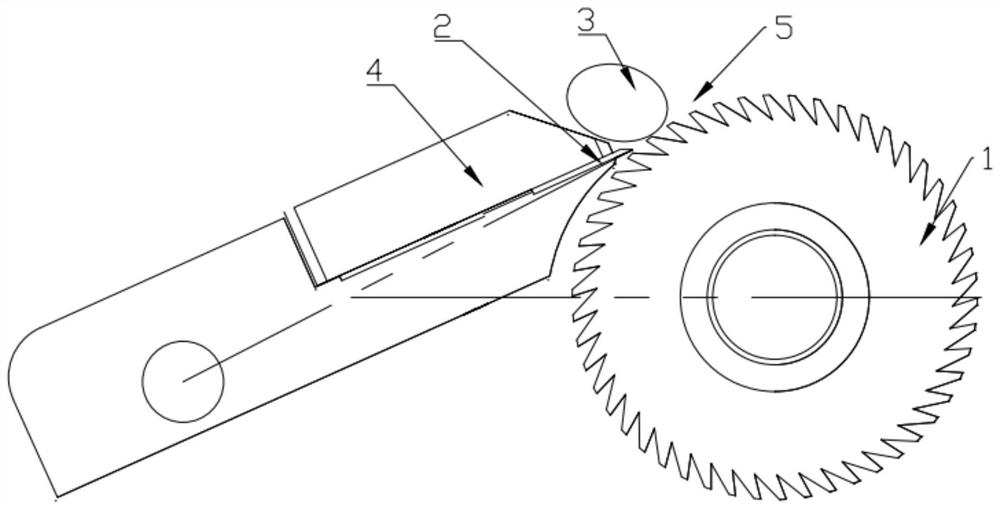

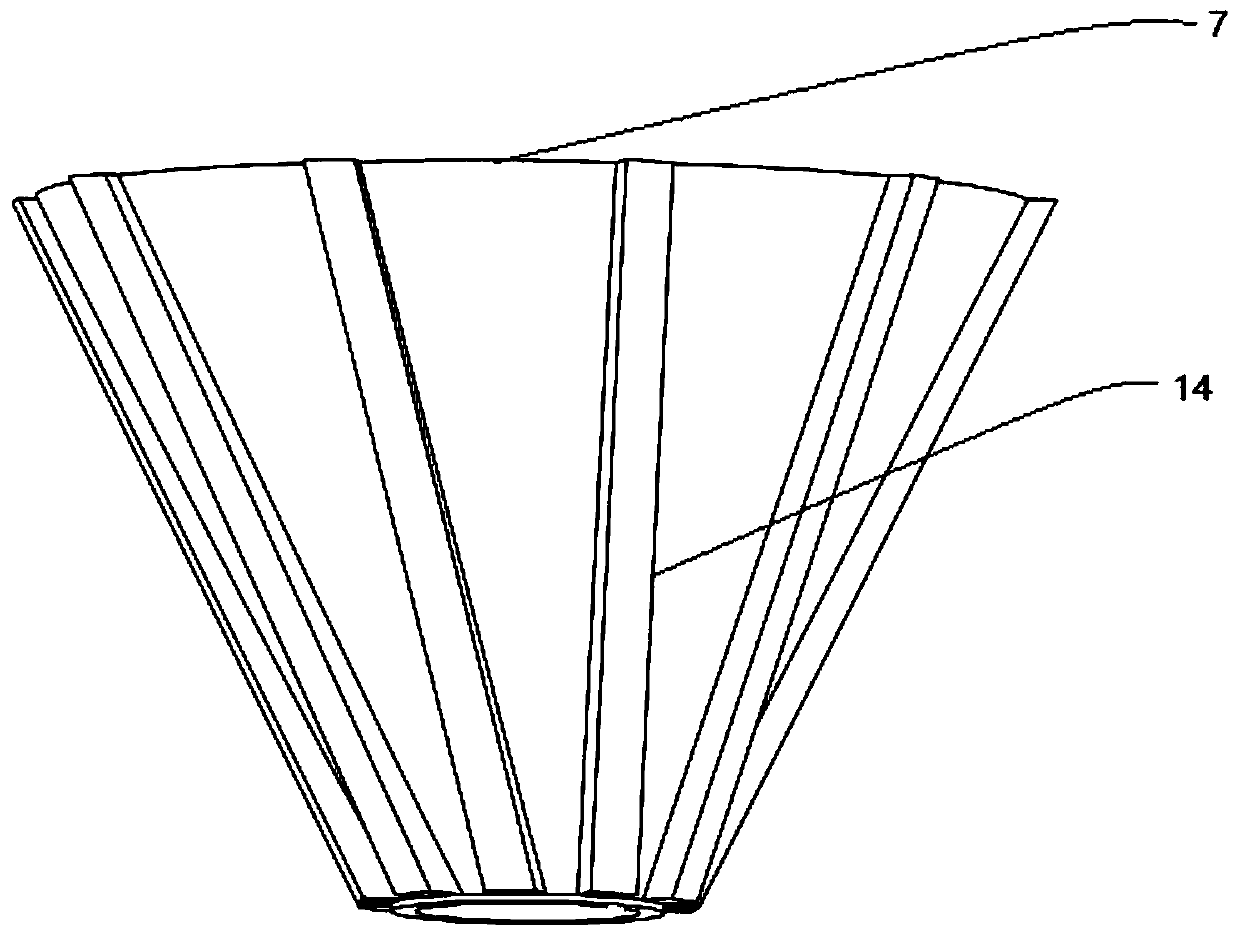

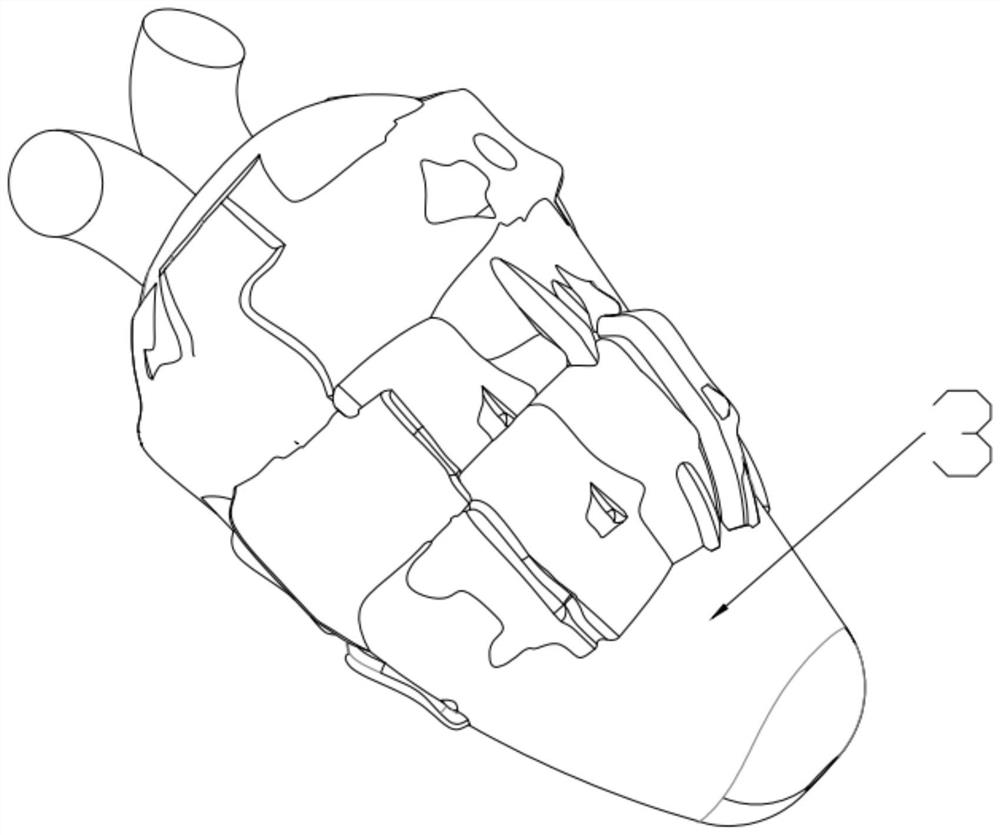

A kind of chicken heart oil removing device and chicken heart oil removing method

ActiveCN114271307BComplete shapeHigh degree of automationConveyorsPoultry processingPetroleum engineeringChemistry

The invention provides a chicken heart oil removing device, comprising an oil removing component and a flattening component, wherein the oil removing component includes an axially rotatable oil removing round roller knife and a relatively static oil removing blade knife. The oil-removing round roller knife is inclined radially, and there is a gap for chicken oil to pass between the oil-removing round roller knife and the oil-removing blade. A storage cavity for temporarily storing chicken hearts is formed, and the flattening component can reciprocate along the storage cavity to push the chicken hearts into the storage cavity; the film-shaped chicken fat is subjected to centrifugal force and constantly contacts the oil-removing round roller knife and oil-removing blade knife Compared with the prior art, the degree of automation is high, the shape of the chicken heart after oil removal is complete, and the chicken oil is removed while turning the chicken heart, and the production efficiency is greatly improved.

Owner:朗易智能科技(天津)有限公司

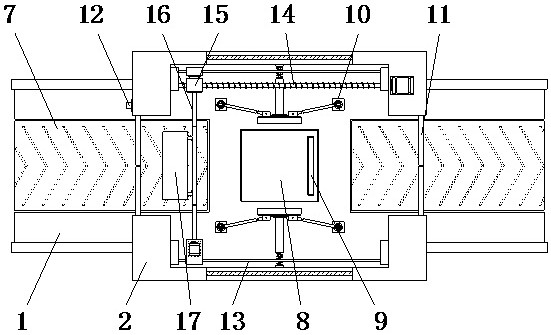

Totally sealed high protection numerically-controlled machine tool capable of inducing feeding and discharging automatically

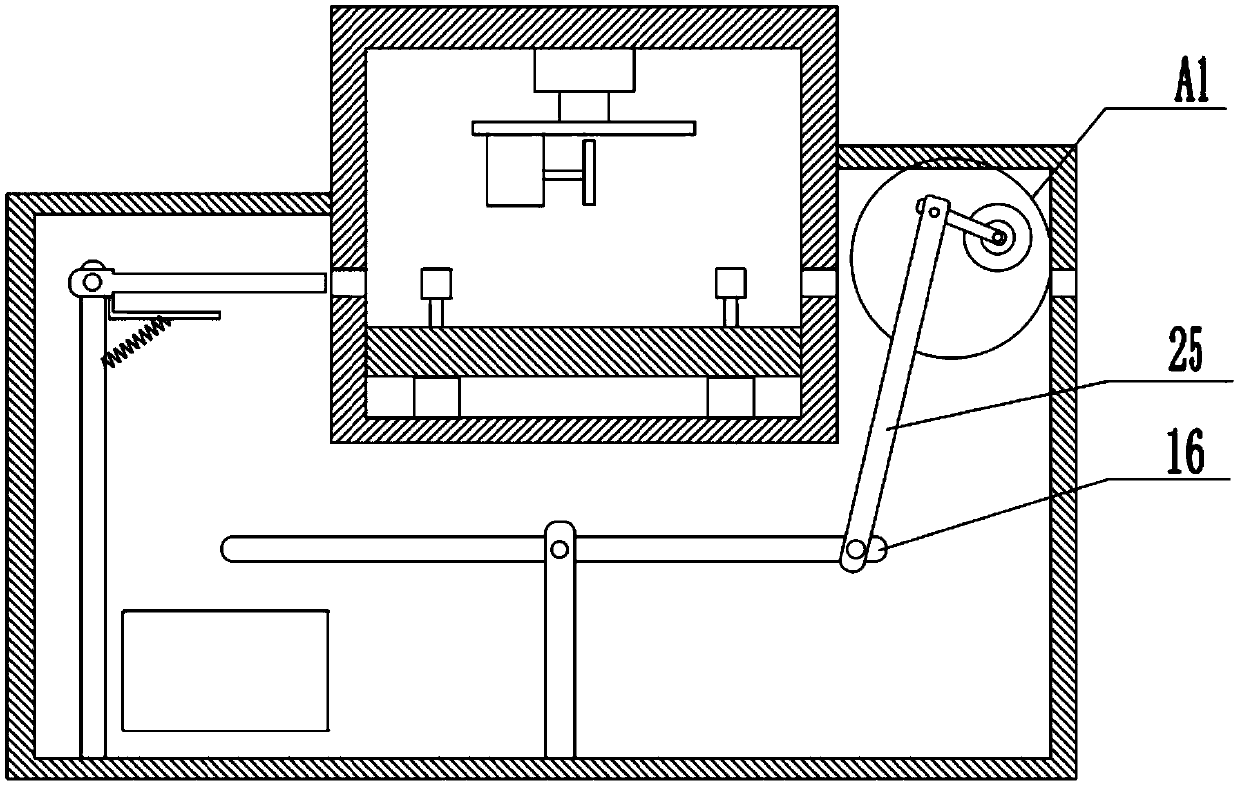

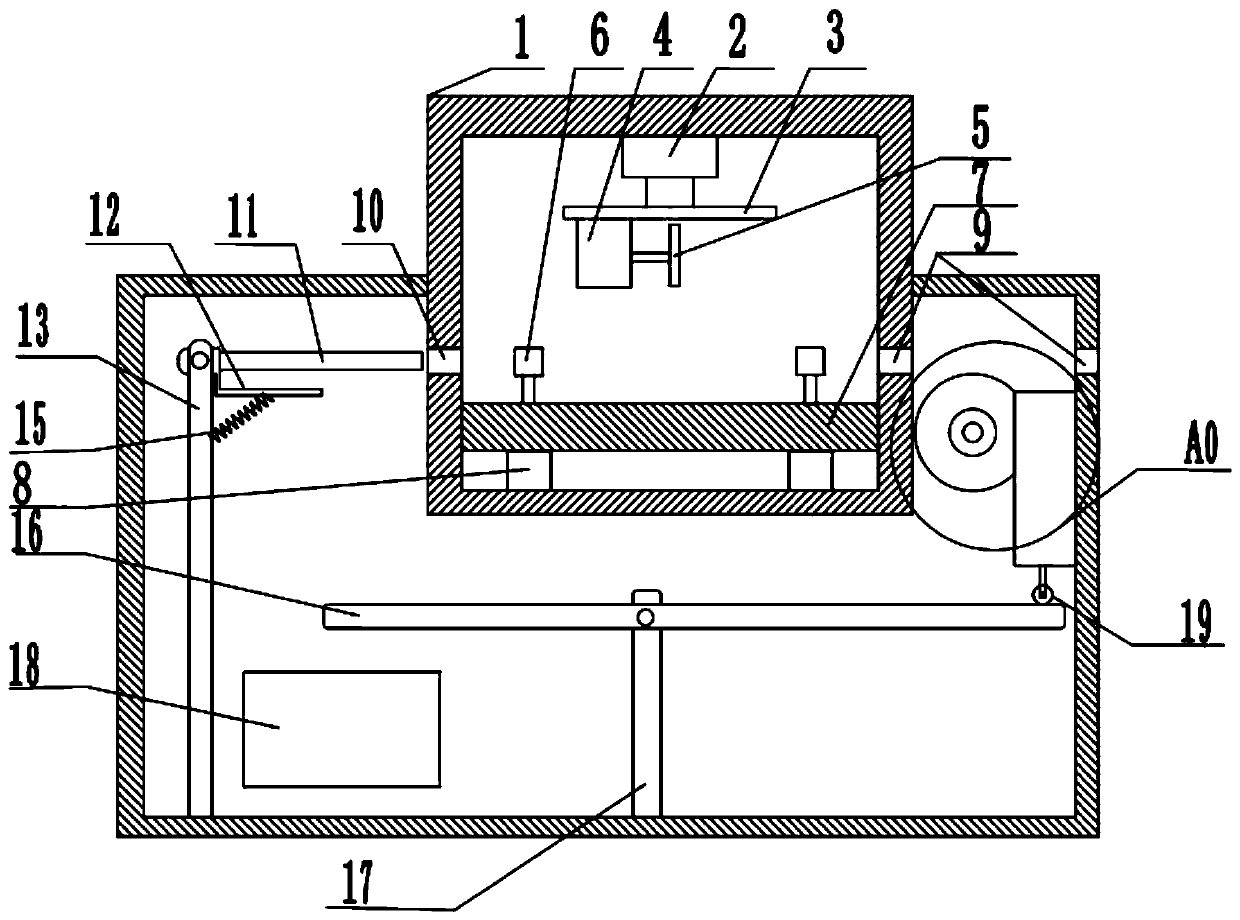

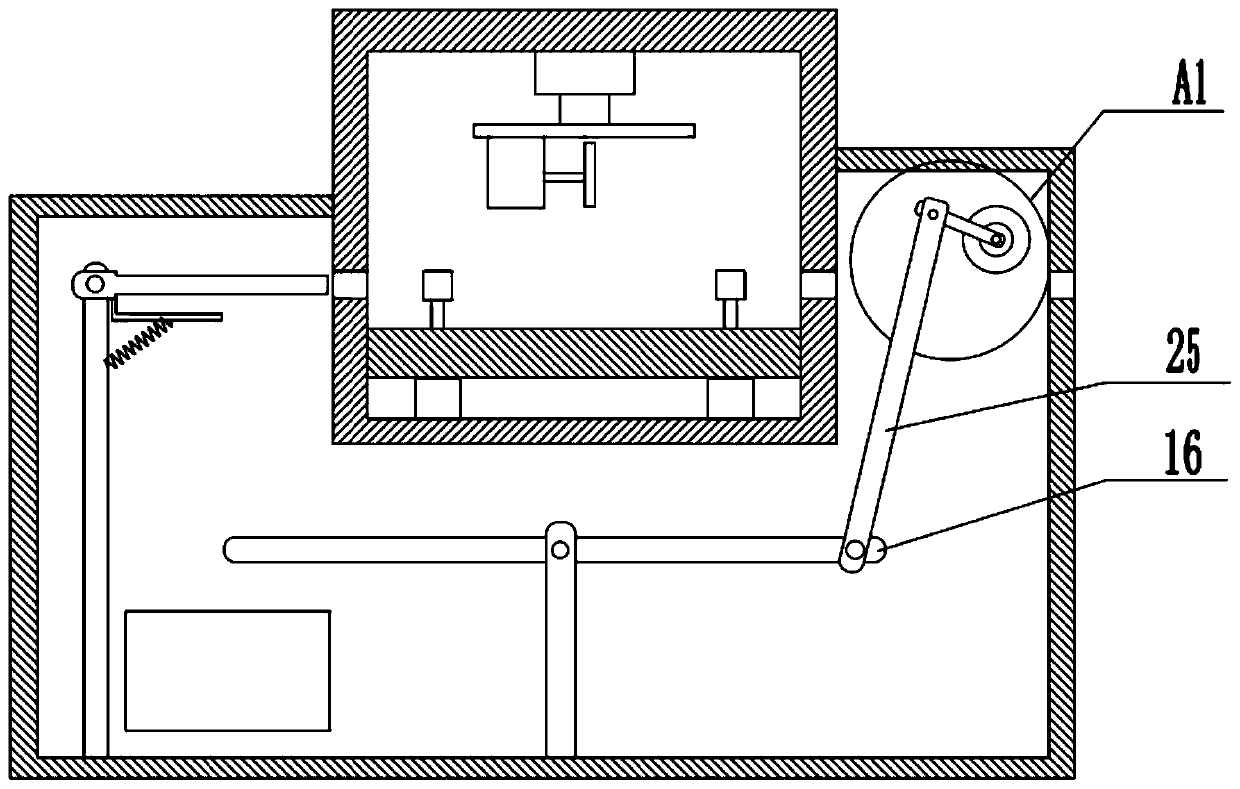

InactiveCN112247180AHigh precisionHigh degree of automationFeeding apparatusPositioning apparatusNumerical controlTransmission belt

The invention discloses a totally sealed high protection numerically-controlled machine tool capable of inducing feeding and discharging automatically. The totally sealed high protection numerically-controlled machine tool comprises a working rack, transmission belts, induction doors, a lead screw and inner slide bars. A protecting hood is fixedly mounted in a middle position of the upper surfaceof the working rack, the transmission belts are symmetrically mounted on two sides in the working rack, the induction doors are movably mounted on two sides of the protecting hood, the lead screw is rotatably mounted on the inner side of the protecting hood, the inner slide bars are fixedly mounted on two sides in a processing plate, a collecting groove is reserved in the working rack, a middle electric lifting bar is fixedly mounted in a middle position in the collecting groove, and an adjusting tooth block is fixedly mounted on the right side of the lower surface of the processing plate. Thetotally sealed high protection numerically-controlled machine tool capable of inducing feeding and discharging automatically adopts a novel structural design, so that the device can feed and discharge materials automatically, and therefore, the processing mechanical degree is improved. A processing limiting structure is arranged in the device, so that the stability and the precision of a processed part in the processing course are improved.

Owner:郑学伟

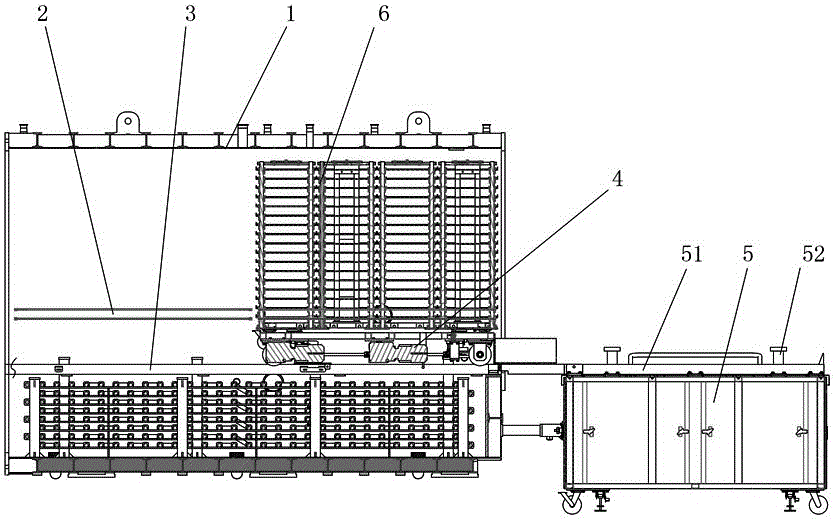

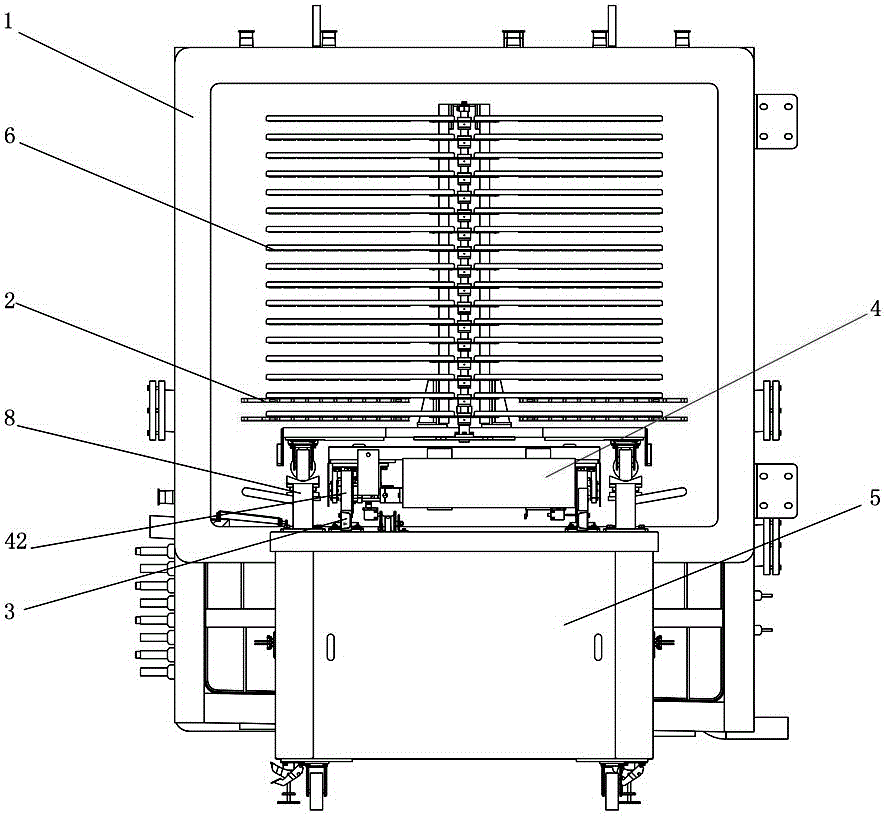

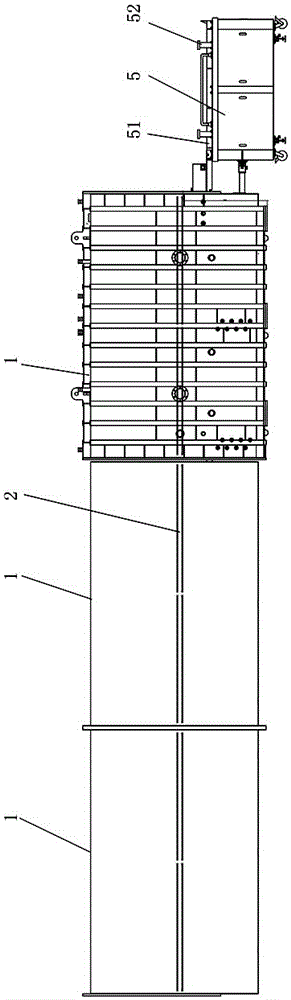

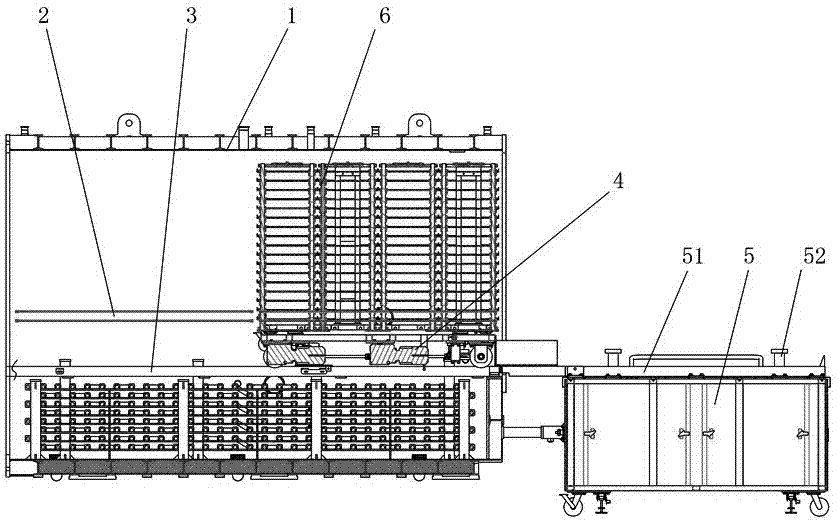

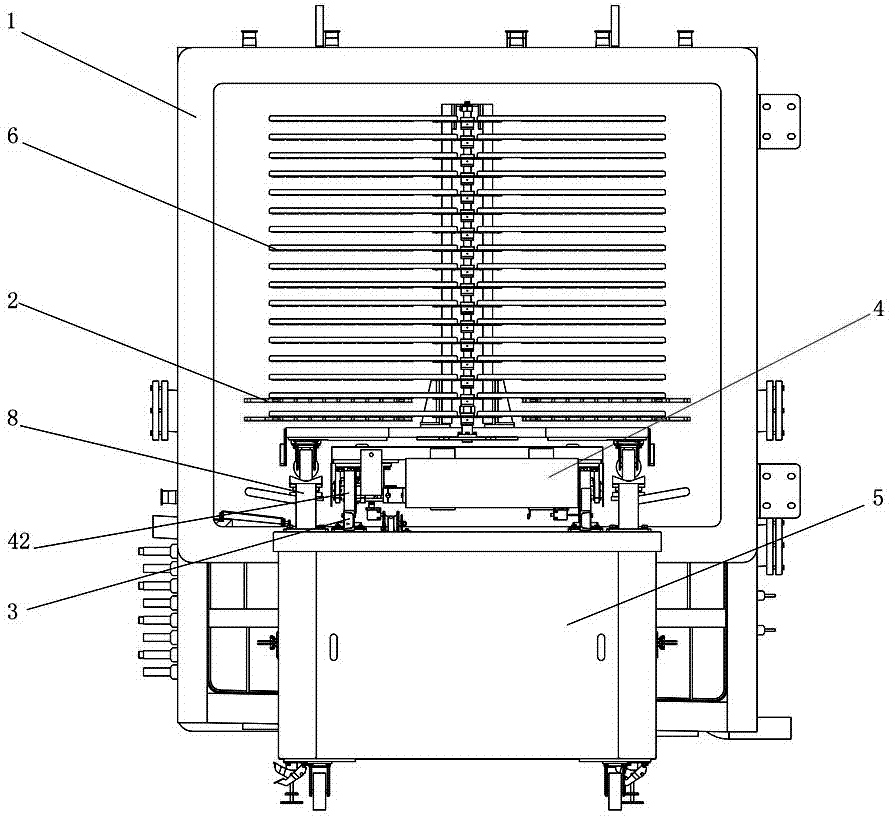

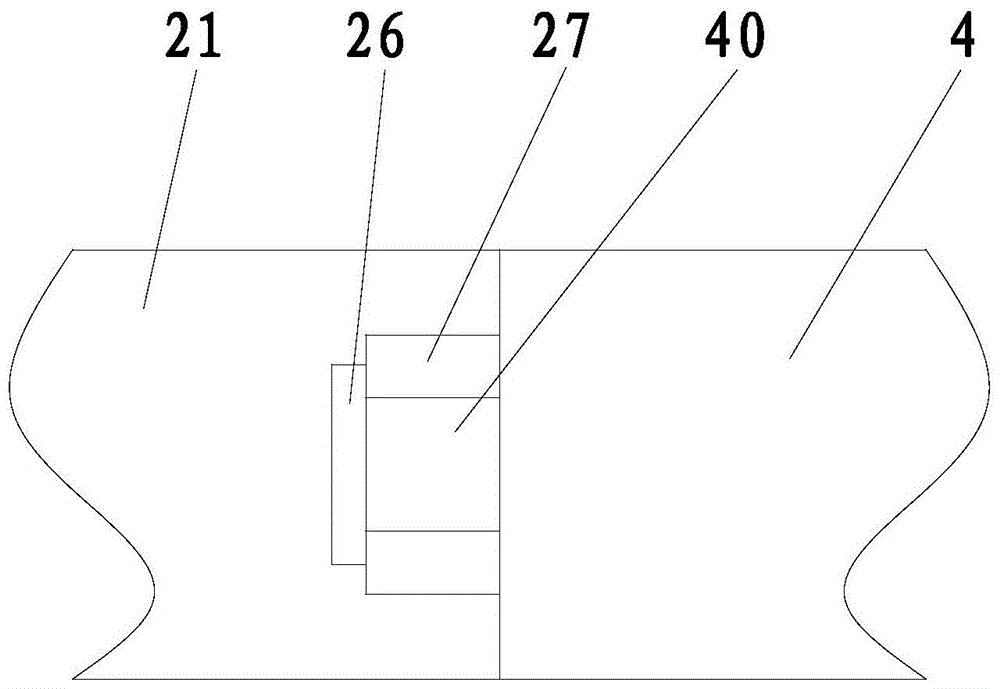

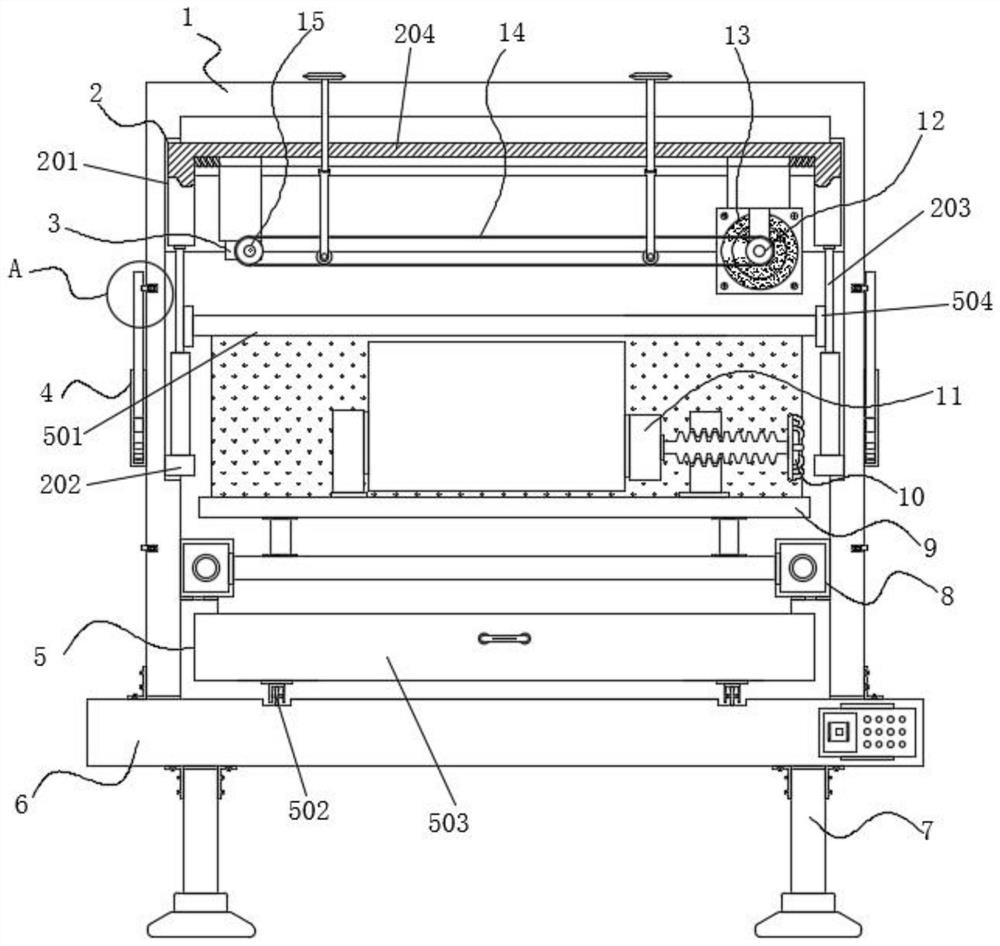

Freeze drier

ActiveCN105091507ARealize automatic feeding and dischargingCompact structureDrying solid materials without heatButt jointFreeze-drying

The invention discloses a freeze drier. The freeze drier comprises freeze-drying boxes. Material transfer bottom rails are arranged in the freeze-drying boxes in the feed direction. Freeze-drying plate layer units are arranged on at least one sides of the material transfer bottom rails. The freeze drier further comprises movable trolleys and material transfer frames connected with the movable trolleys in a butt joint manner. The movable trolleys can move on the material transfer bottom tails and drive the material transfer frames to be in butt joint with the freeze-drying plate layer units. The freeze drier has the beneficial effects of being high in automation degree, compact in whole-machine structure and high in production efficiency.

Owner:TRUKING TECH LTD

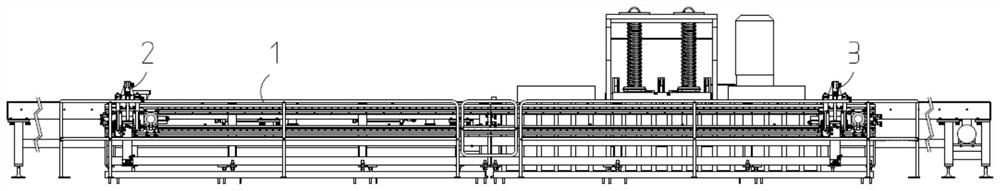

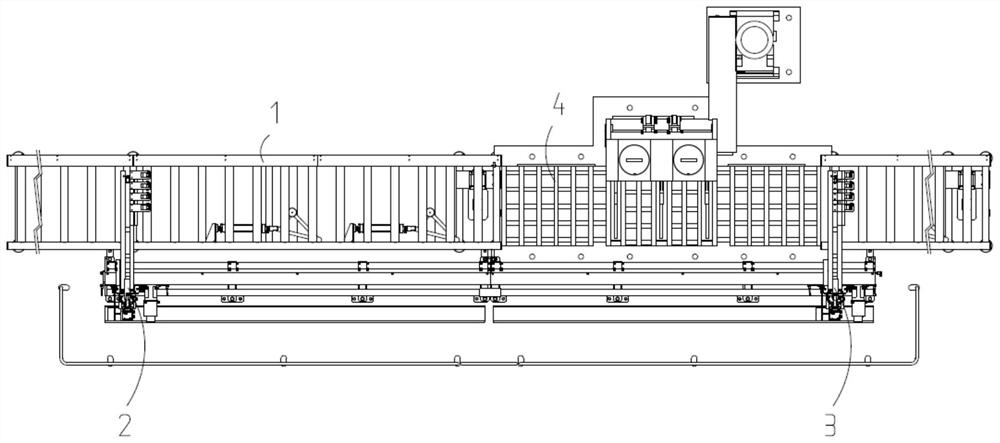

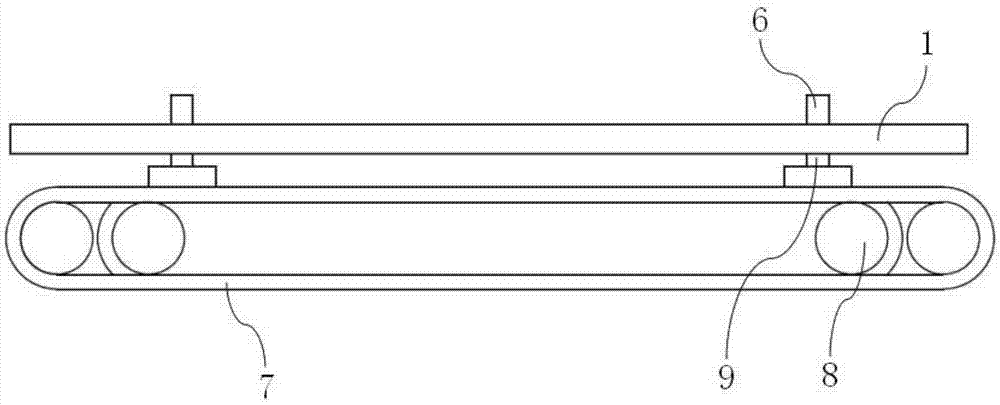

Aligned feeding device and surface dirt cleaning machine for aluminum mold plate

ActiveCN111822449ARealize automatic feeding and dischargingLabor savingConveyorsCleaning processes and apparatusEngineeringPower unit

The invention belongs to the technical field of surface dirt cleaning equipment for aluminum mold plates and discloses an aligned feeding device. The aligned feeding device comprises a feeding rack, afeeding roller, a first chain transmission unit, a roller power unit and a correction unit. The correction unit comprises a linear power part provided with a linear moving rod, a triangular transmission rack and a push cylinder. The triangular transmission rack comprises a first connecting end, a second connecting end and a third connecting end arranged triangularly. Compared with related art, the aligned feeding device can feed the aluminum mold plates automatically, and can push the aluminum mold plates rightward to be aligned continuously by reciprocating action of the correction unit, sothat the aluminum mold plates of different rules and dimensions can be aligned rightward. The invention further discloses a surface dirt cleaning machine for the aluminum mold plate. The surface dirtcleaning machine comprises the aligned feeding device, and can push the aluminum mold plates inside and outside a throwing and beating table main body through a pushing unit to feed and discharge thealuminum mold plates automatically, so that the operation efficiency is improved.

Owner:SNTO TECH GRP

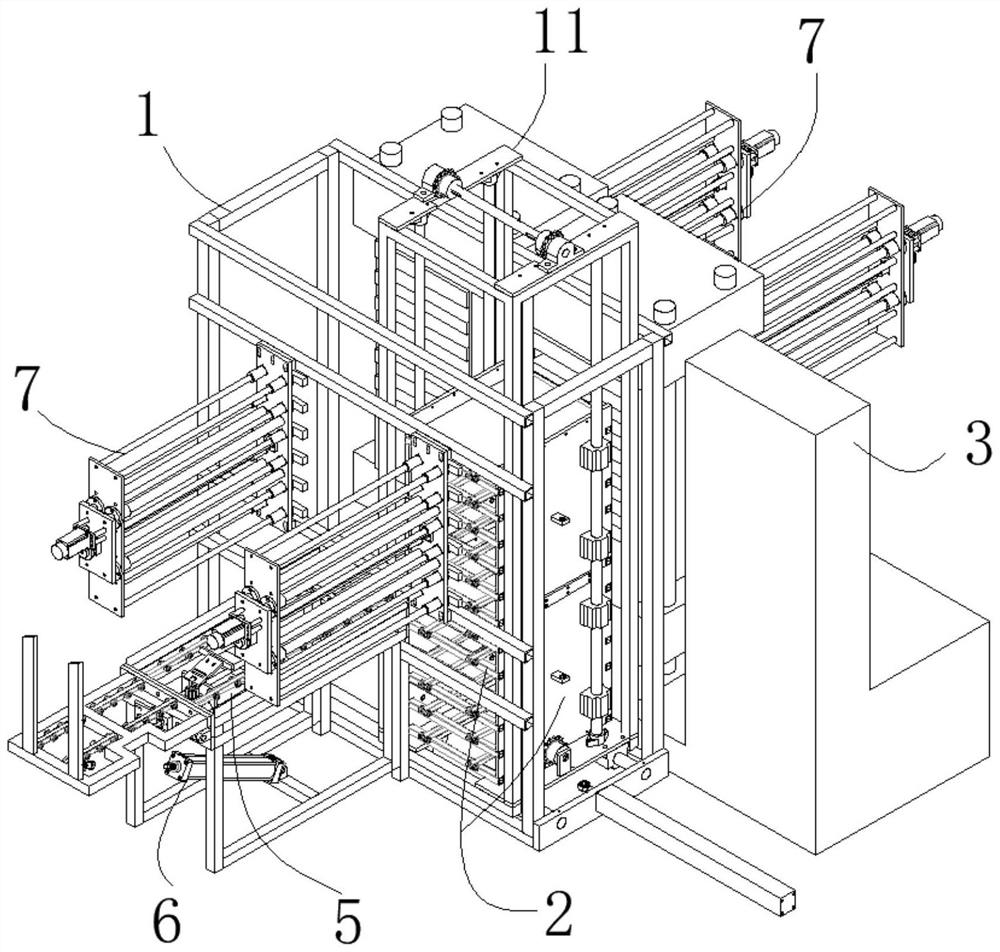

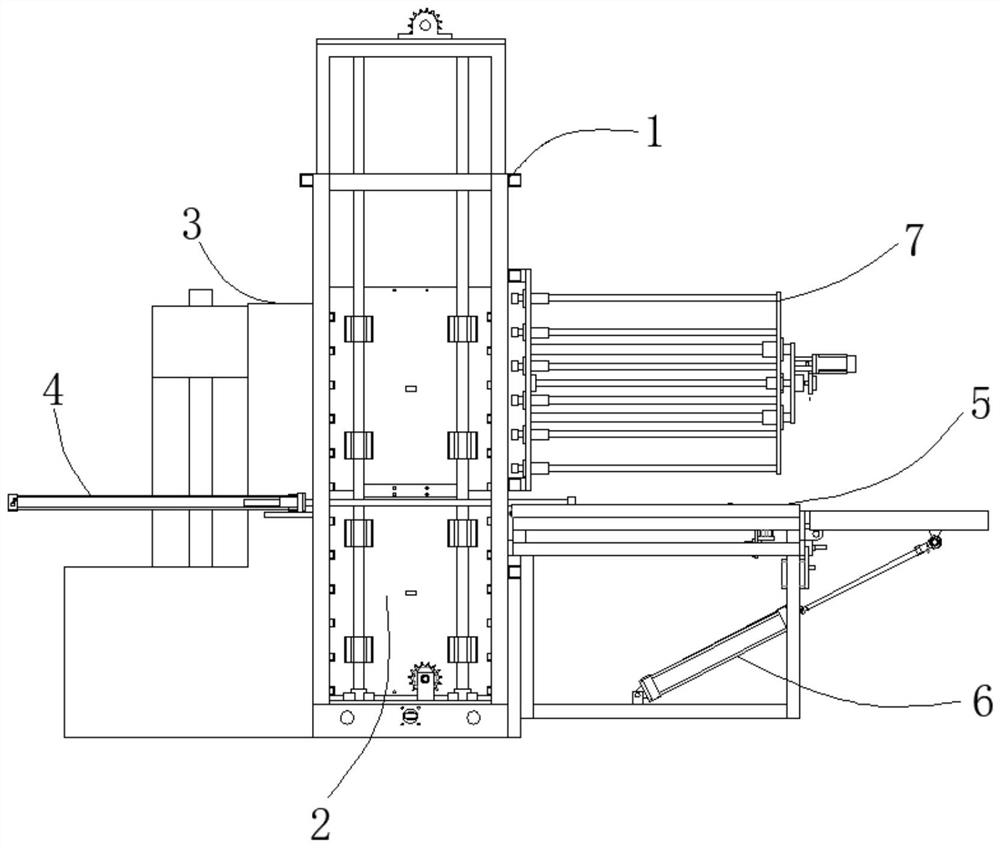

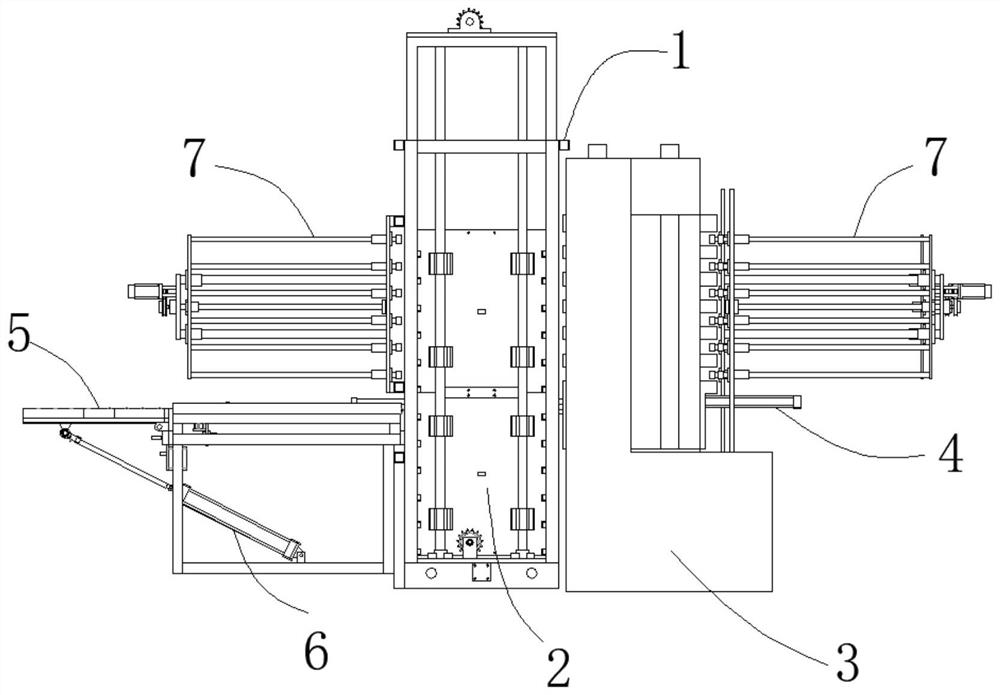

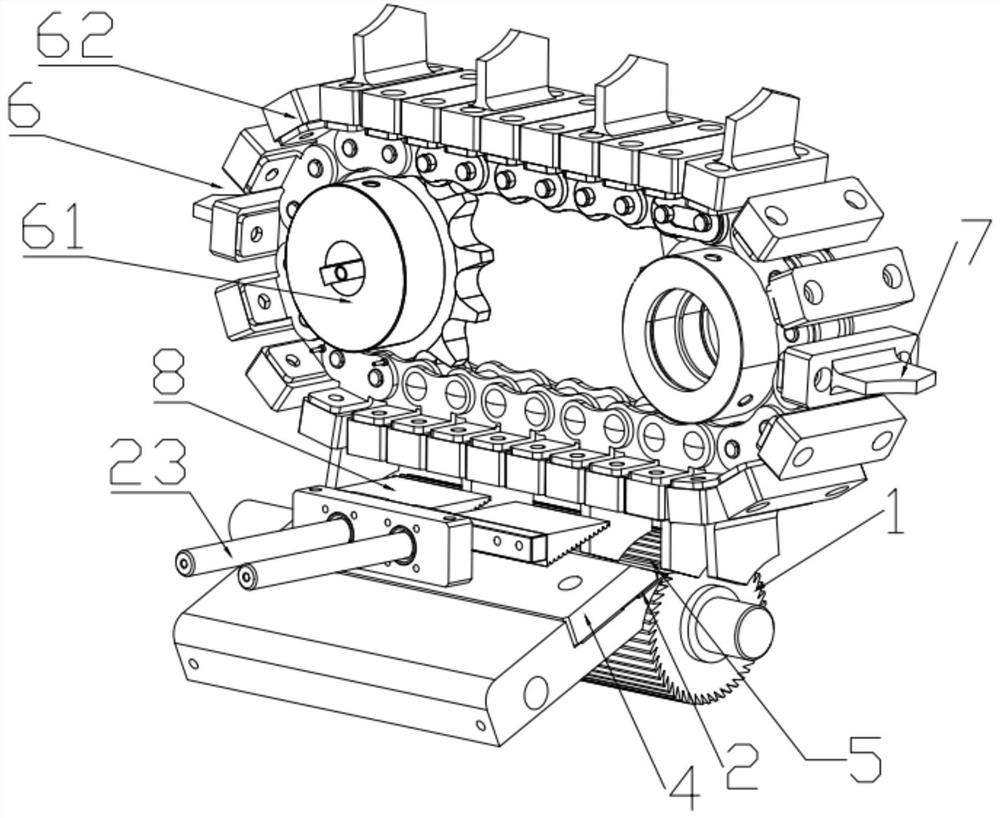

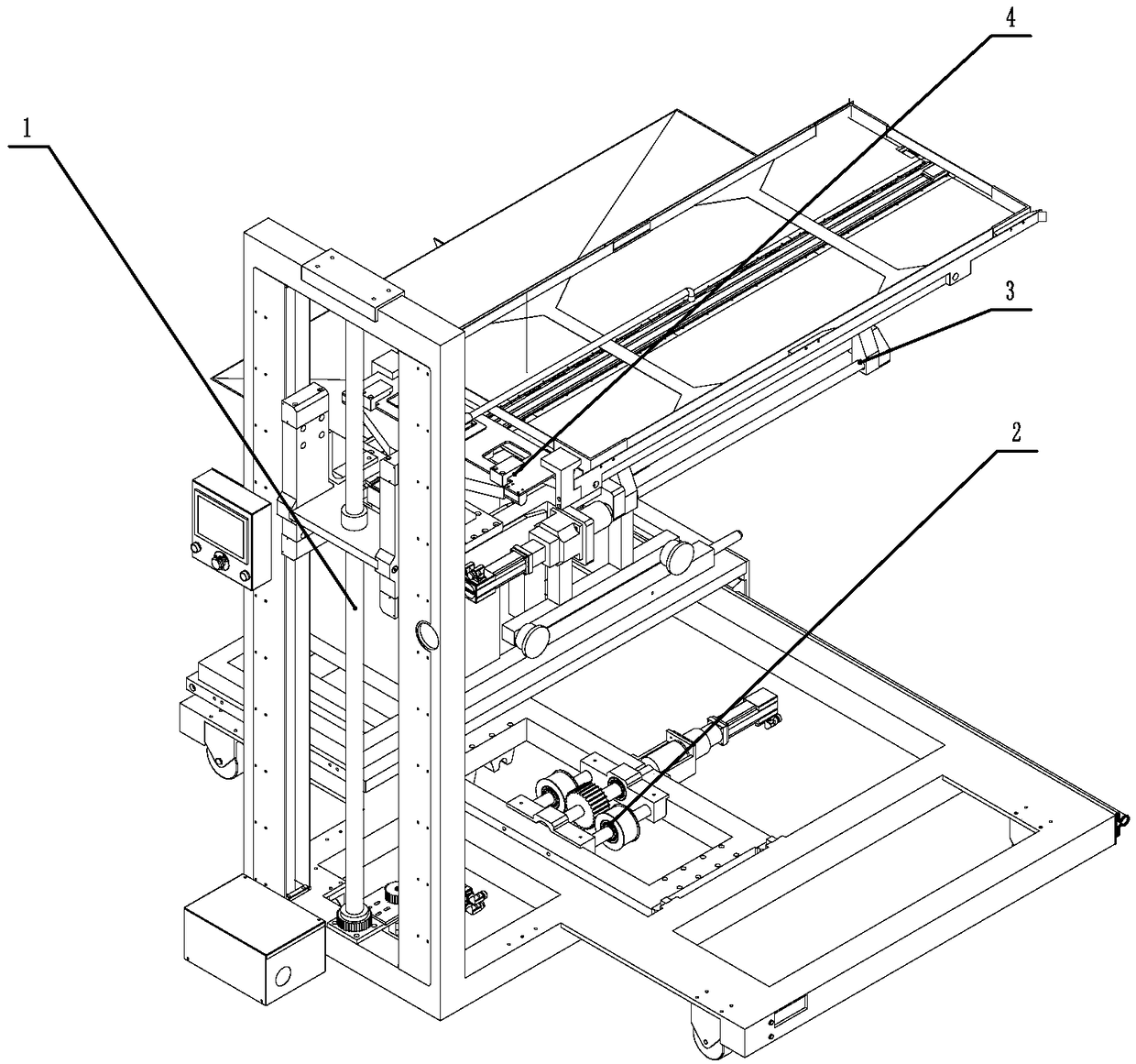

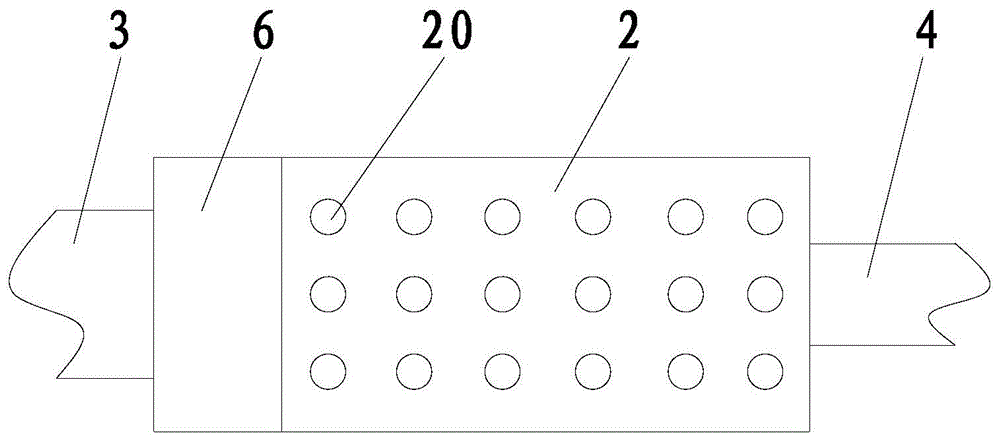

Material conveying device capable of circularly feeding and discharging material layers

PendingCN114476638ARealize automatic feeding and dischargingRealize material transferConveyor partsPush and pullEngineering

The invention discloses a material conveying device for circulating feeding and discharging layers, which comprises a rack, a feeding table and a discharging table, one side of the rack is connected with the feeding table, the other side of the rack is connected with the discharging table, and a laminating machine for processing a material tray is arranged between the rack and the discharging table; a material tray is firstly conveyed from the feeding table to enter the laminating machine through the rack; a movable frame is arranged in the rack, a guide rail for horizontal displacement of the movable frame is arranged at the lower end of the rack, a guide groove is formed in the lower end of the movable frame, the guide rail is in sliding connection with the guide groove, a material conveying box is arranged in the movable frame, the movable frame is provided with a lifting mechanism for vertically conveying the material conveying box, and the lifting mechanism conveys the material conveying box to be communicated with the feeding table and the laminating machine; the push-pull mechanism used for pushing and pulling the material trays is arranged on one side of the rack, the push-pull mechanism pushes in and out the material trays to be treated or treated, automatic feeding, discharging and transferring of the material trays are achieved, the automation degree is high, and the production efficiency is improved.

Owner:东莞市量必达智能科技有限公司

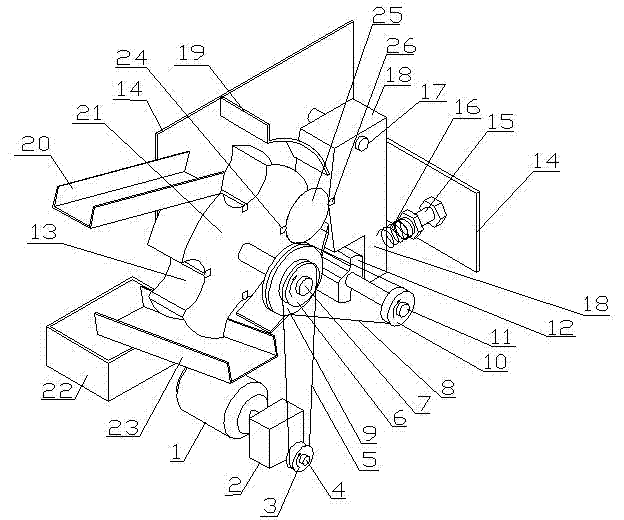

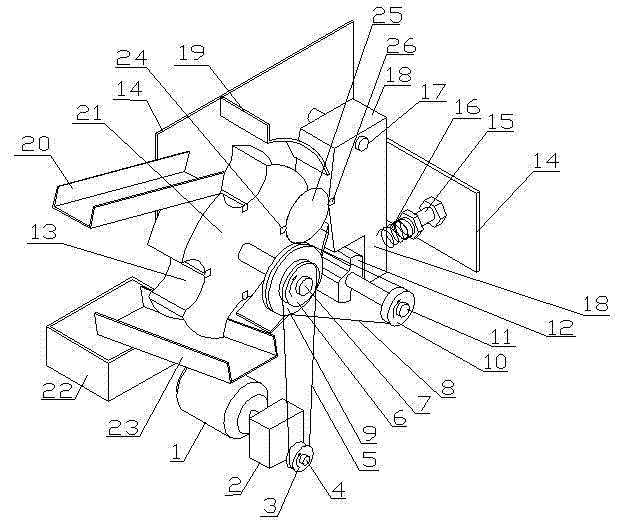

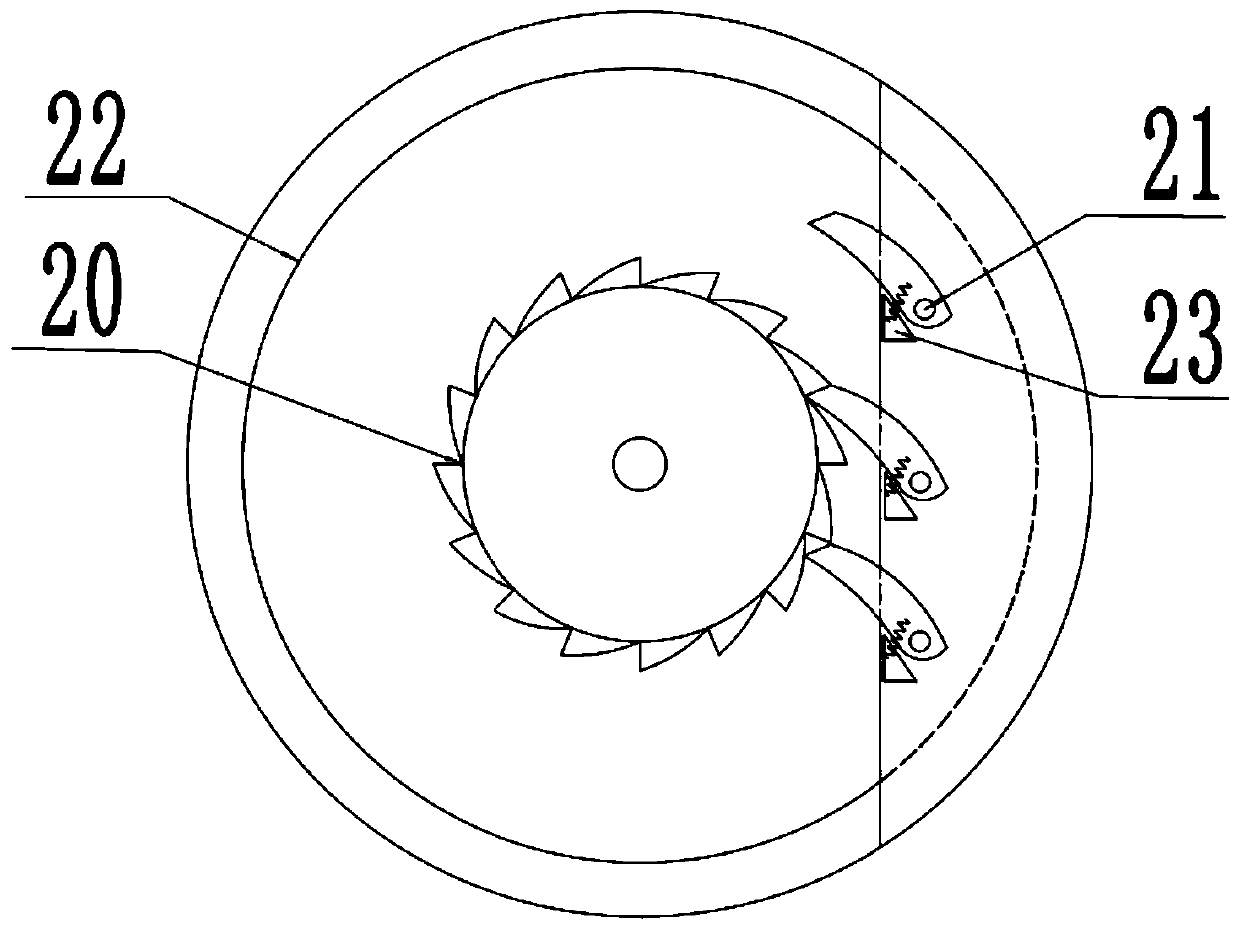

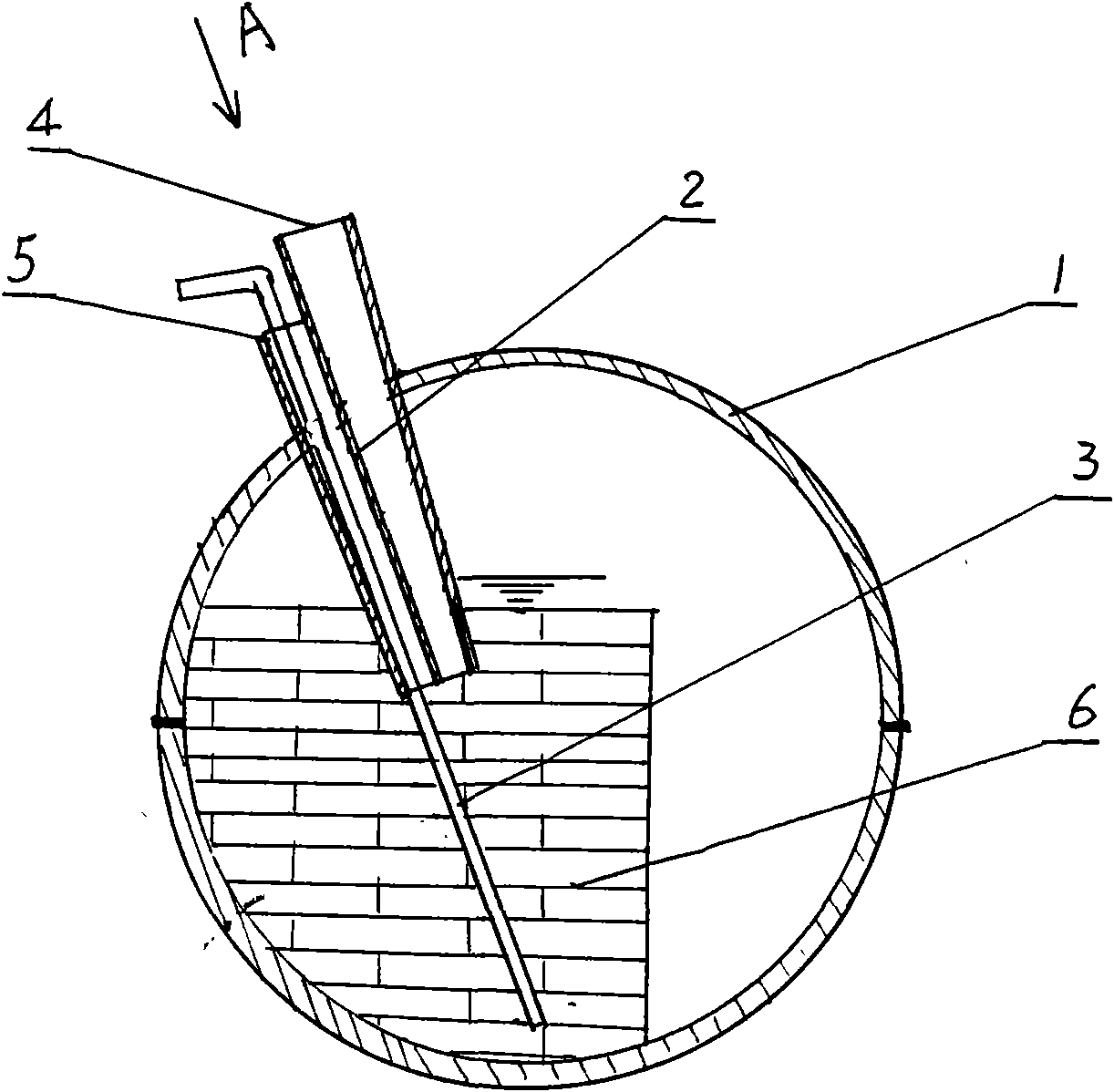

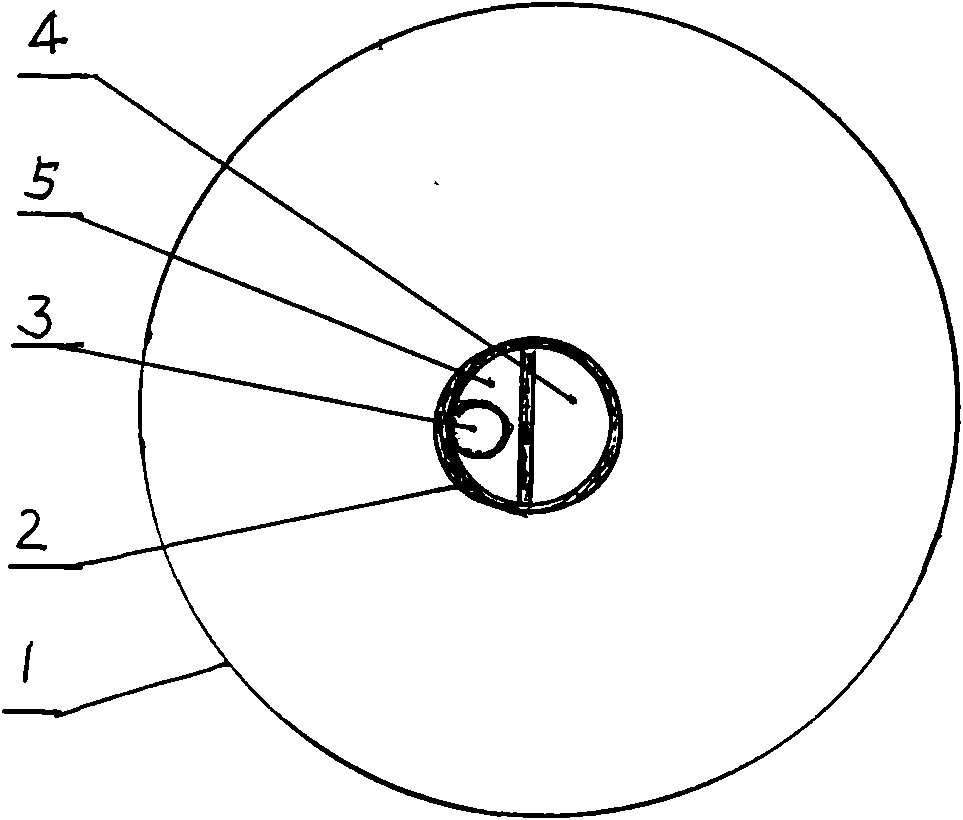

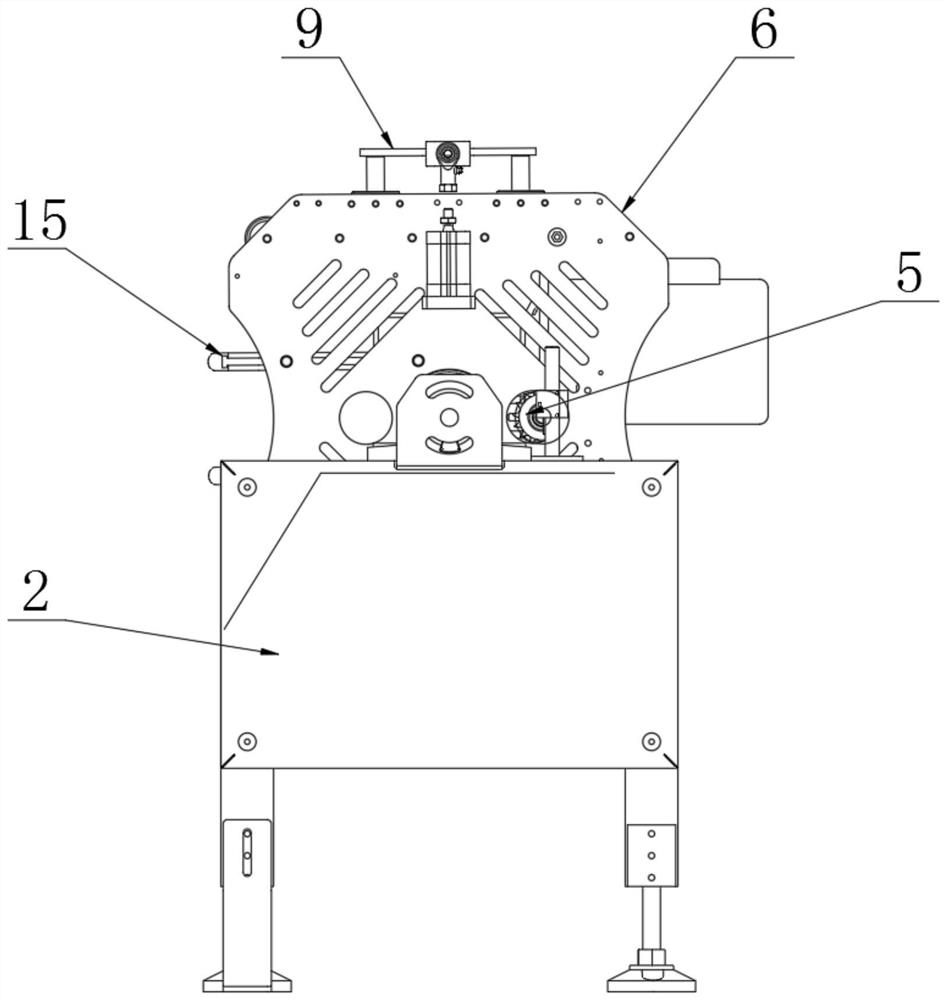

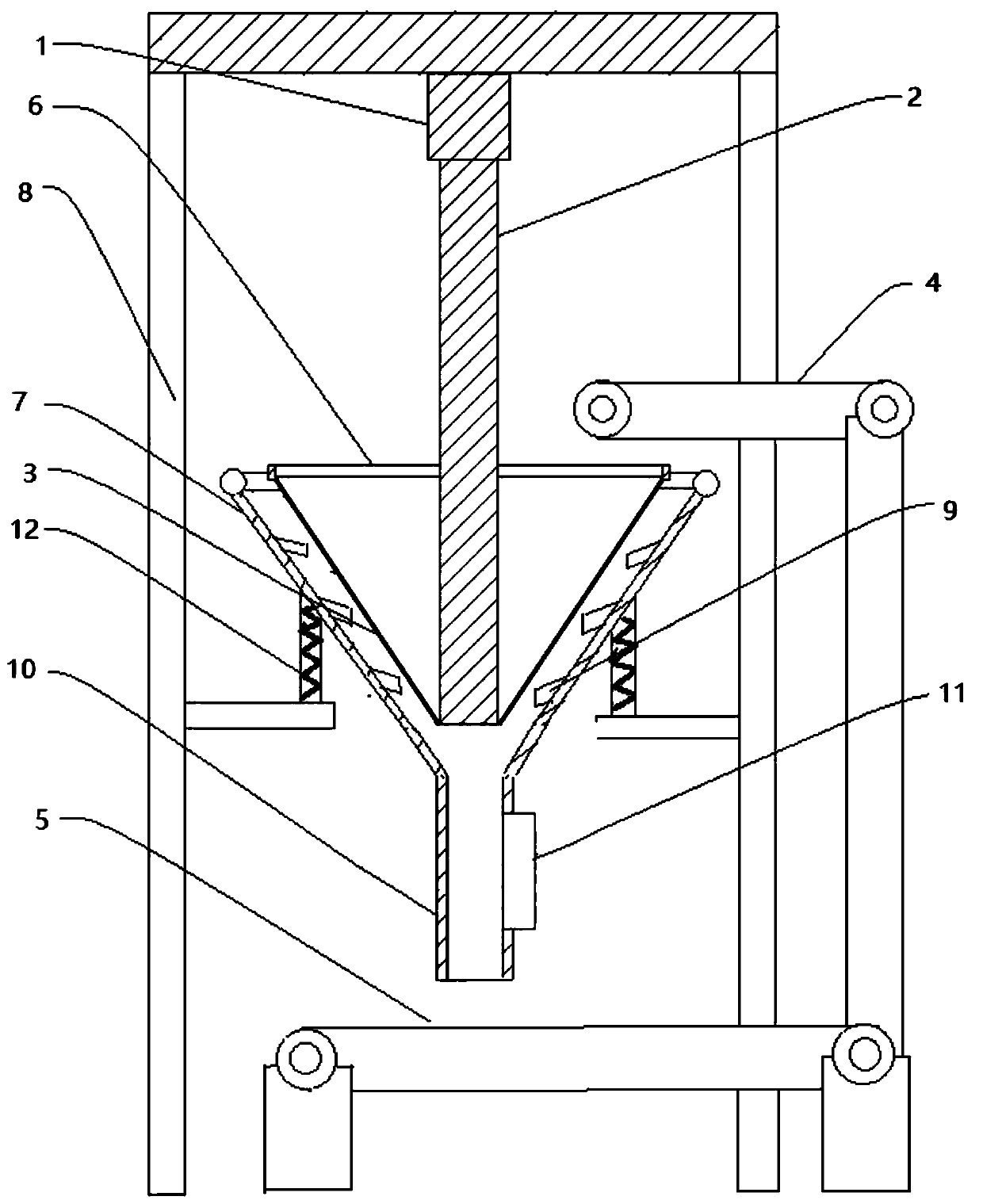

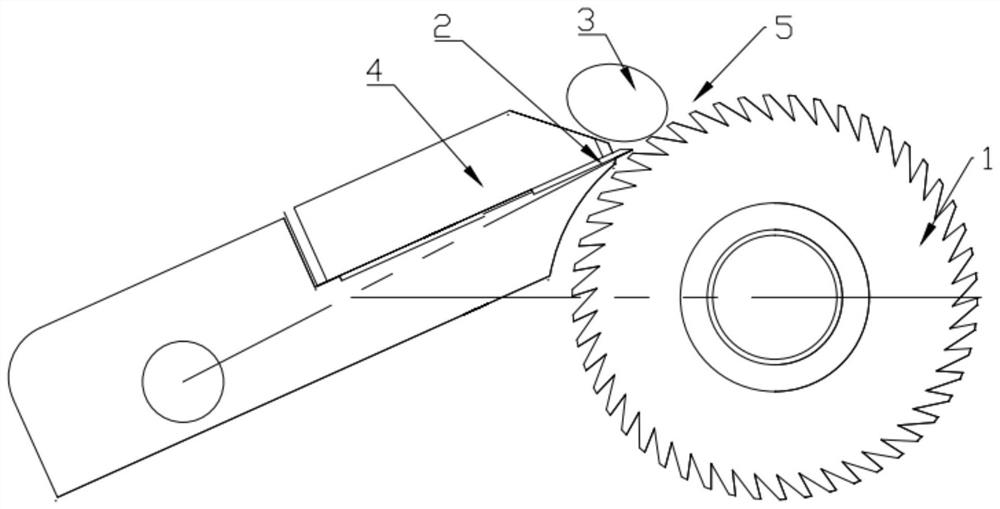

Device for knocking and splitting diamond synthetic block

The invention discloses a device for knocking and splitting a diamond synthetic block, which comprises a frame, and a main shaft, a cam shaft and a pin shaft all arranged on the frame, wherein the main shaft is provided with a rotary workbench, the cam shaft is provided with a cam, the pin shaft is rotatably provided with a swing block, the cam is positioned between the rotary workbench and the swing block, and the cam comes into traveling contact with the inner side of the swing block; and the main shaft is in transmission connection with a power mechanism and the cam shaft. Under the driving of the power mechanism, the rotary workbench completes one rotation and the cam completes two rotations, namely, while the rotary workbench completes one rotation, the swing block knocks against synthetic blocks on the rotary workbench four times so as to knock and split four synthetic blocks; the device is simple in structure, low in labor intensity of workers and high in working efficiency, can effectively avoid the loss of diamond and remarkably reduces the production cost.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

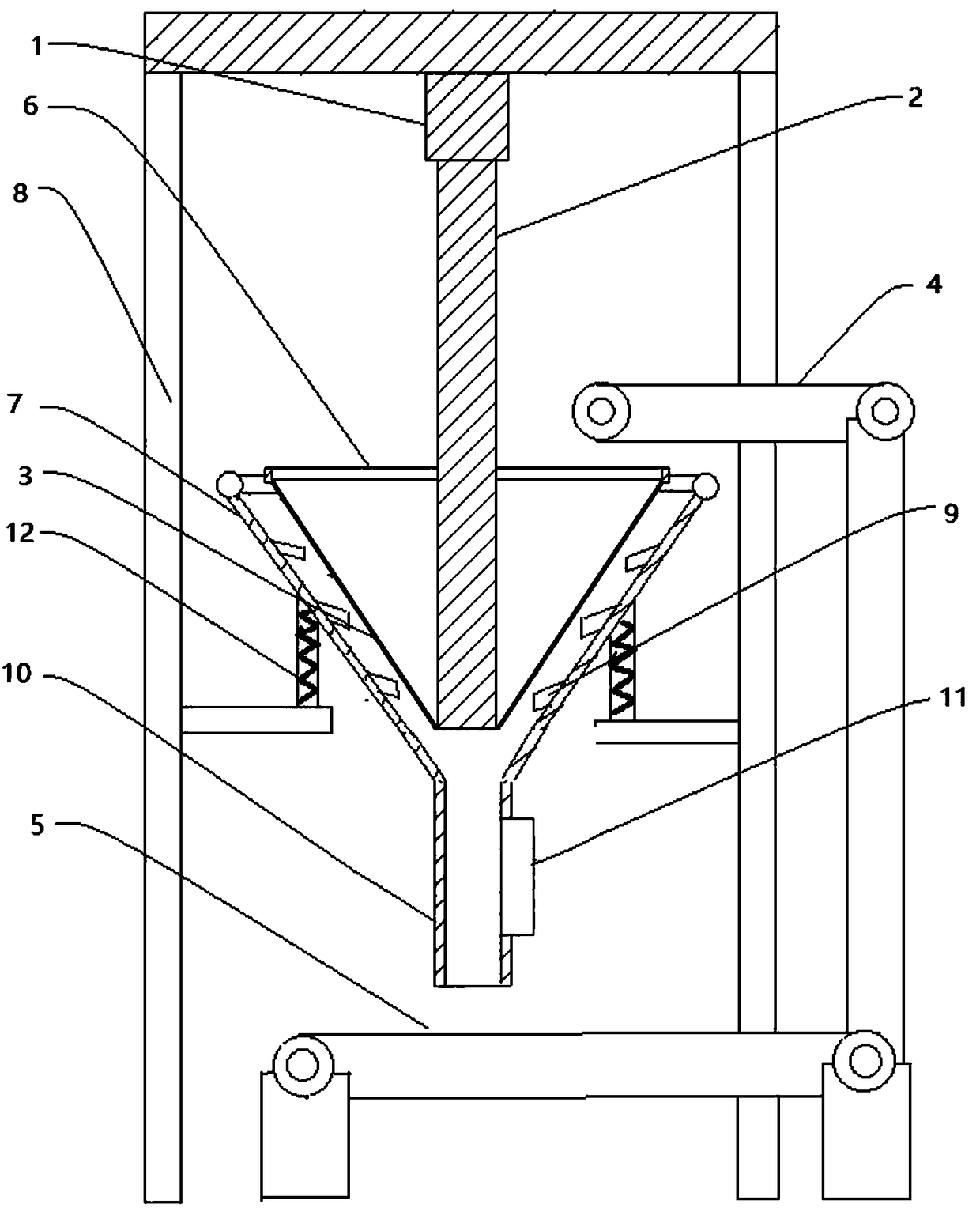

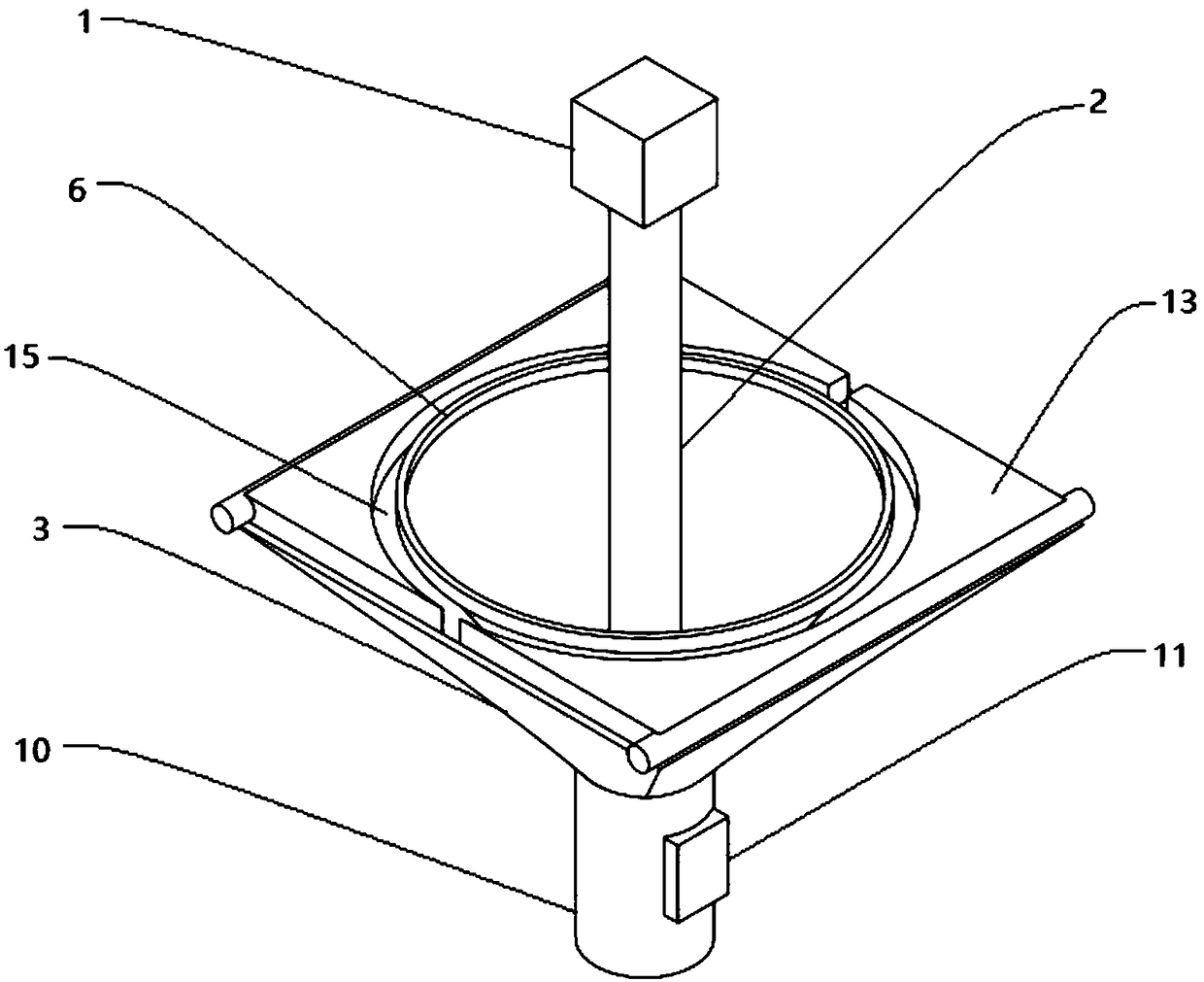

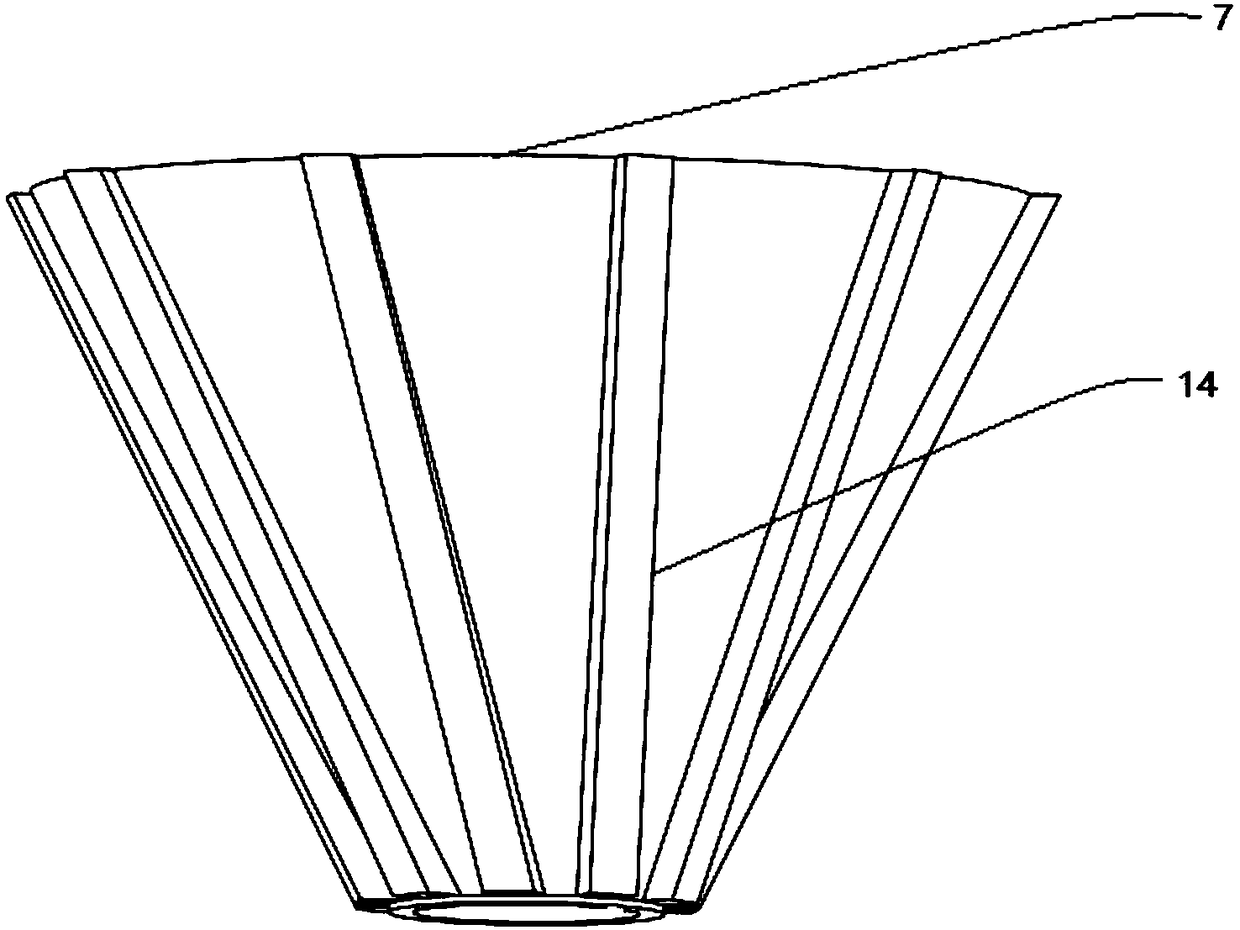

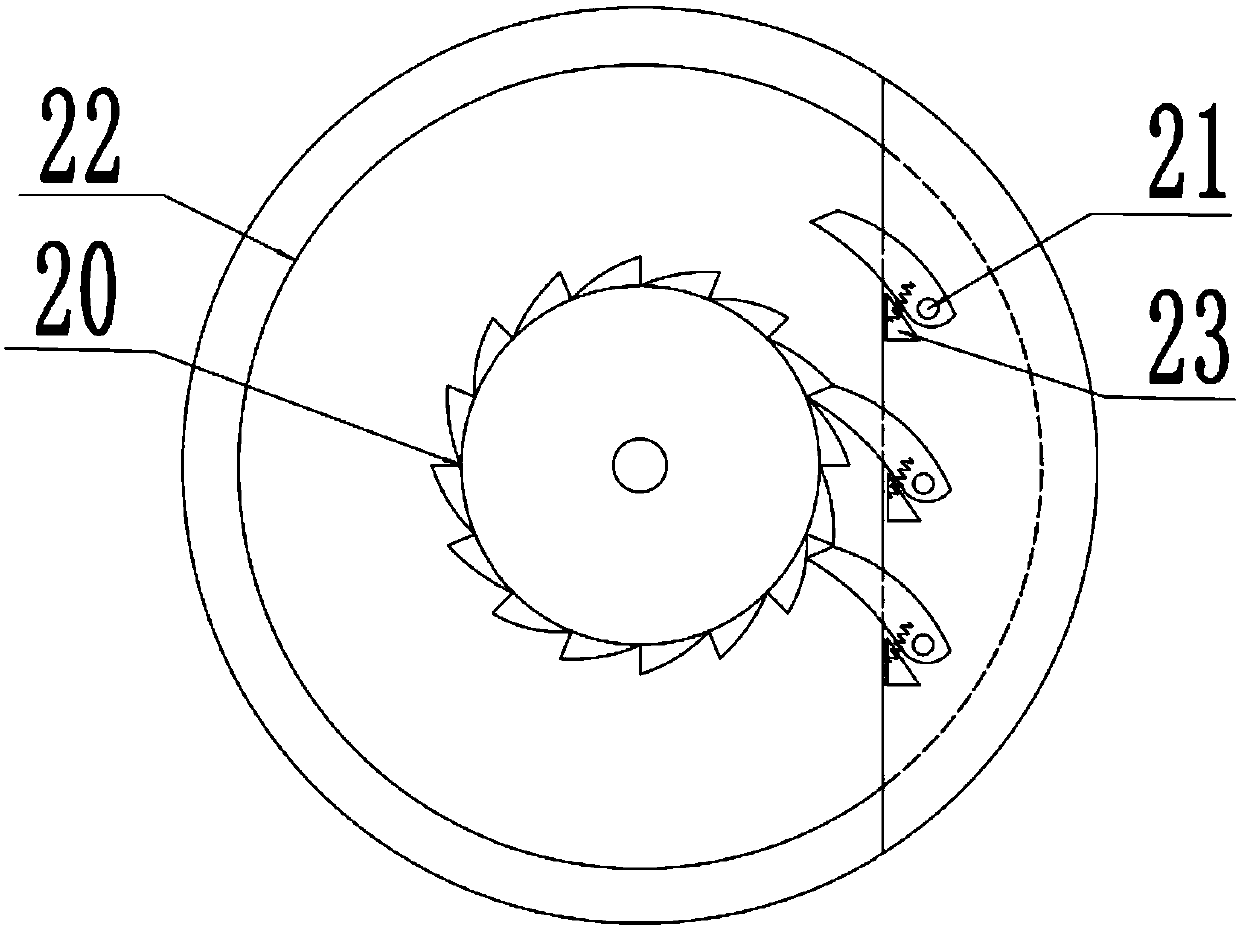

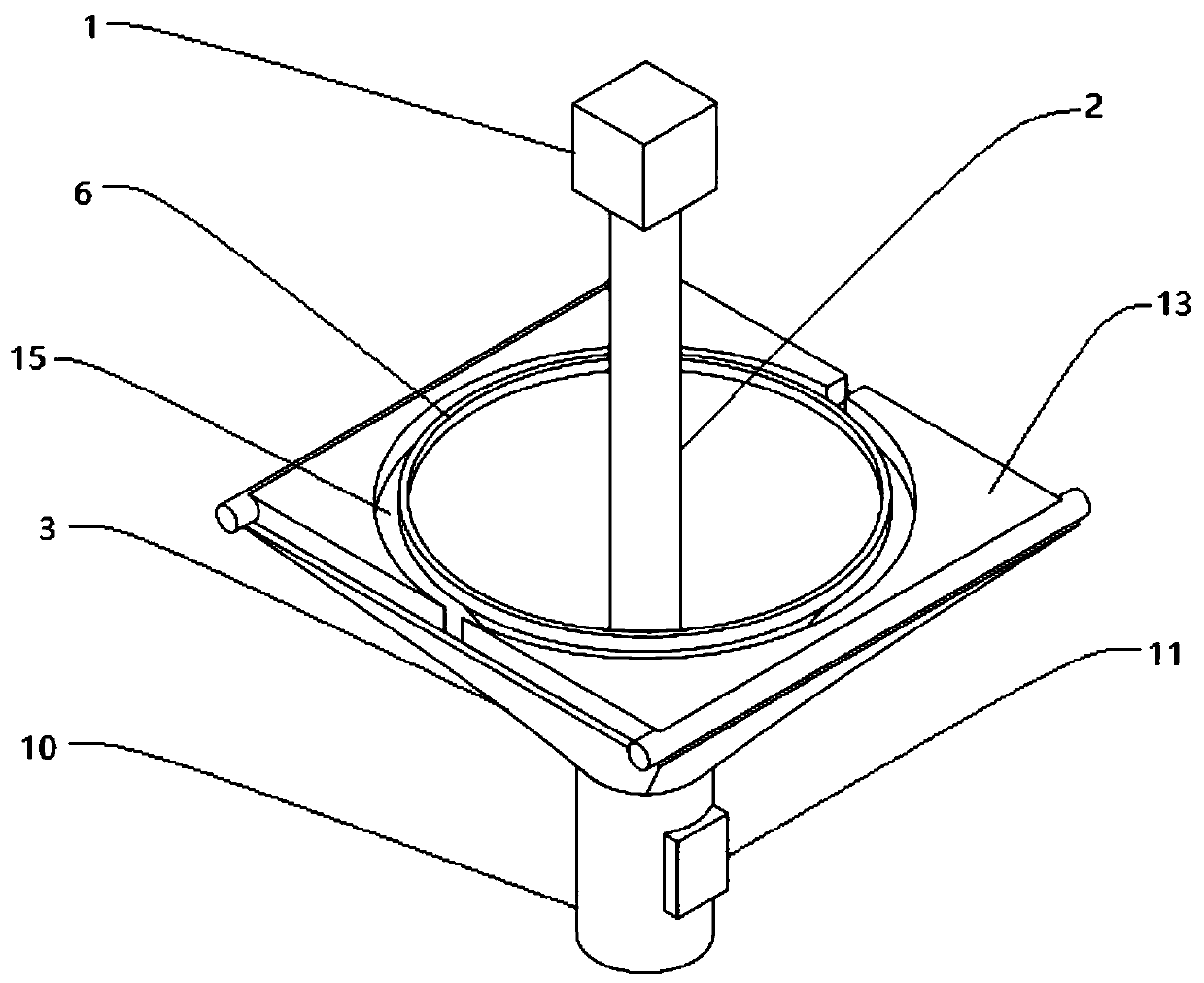

Centrifugal soil screening device for soil remediation

ActiveCN108465637AImprove filteringImprove screening efficiencyGas current separationEngineeringDriving mode

The invention discloses a centrifugal soil screening device for soil remediation. The centrifugal soil screening device comprises a driving device, a supporting device and a screen, wherein the driving device is arranged on the supporting device, the screen is in a funnel structure shape with a larger upper part and a smaller lower part, and the driving device is connected to the screen in a driving mode to enable the screen to rotate around the axis. The centrifugal soil screening device for soil remediation has the advantages that automatic feeding, discharging and gravel screening can be realized, labor can be saved, meanwhile, soil accumulation can be effectively prevented, and a better screening effect can be achieved.

Owner:GUANGZHOU FIRST MUNICIPAL ENG CO LTD

A multi-drive chicken heart oil removing device

Owner:朗易智能科技(天津)有限公司

Tube stock cutting device for automotive part manufacturing

ActiveCN109605055AAchieve correctionRealize automatic dischargeOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining

The invention relates to the field of automotive part manufacturing machining, in particular to a tube stock cutting device for automotive part manufacturing. The tube stock cutting device for automotive part manufacturing comprises a box body, a feeding opening and a discharging opening are formed in the box body, the box body comprises a cutting chamber and a power transmission chamber which arearranged up and down, and an electric telescopic rod is arranged at the top of the interior of the cutting chamber. A fixed plate is arranged at the bottom of the electric telescopic rod, a motor isarranged at the bottom of the fixed plate, a cutting knife is connected to a rotary shaft of the motor, and a cutting table is arranged below the cutting knife. The cutting table comprises a supporting plate and supporting blocks, the supporting blocks are arranged on two sides of the bottom of the interior of the cutting chamber, the supporting plate is arranged above the supporting blocks, clamping structures are arranged on two sides of the supporting blocks, and the clamping structures, the feeding opening and the discharging opening are located on a same straight line. The power transmission chamber is provided with a discharging structure, a transmission structure and a feeding structure. According to the tube stock cutting device for automotive part manufacturing, after clamping andcutting of tube stocks are realized, functions of discharging, correcting and automatic circulation of the tube stocks can be realized, and the automatic degree is high.

Owner:宁波隆锐机械制造有限公司

A pipe cutting device for auto parts manufacturing

ActiveCN109605055BAchieve correctionRealize automatic dischargeOther manufacturing equipments/toolsMetal working apparatusElectric machineryMotronic

The invention relates to the field of manufacturing and processing of auto parts, in particular to a pipe cutting device for the manufacture of auto parts, which includes a box body, which is provided with a material inlet and a material outlet, and the box body includes a cutting chamber set up and down and a power transmission Chamber, the top of the cutting chamber is equipped with an electric telescopic rod, the bottom of the electric telescopic rod is provided with a fixed plate, and the bottom of the fixed plate is provided with a motor. Plate and support block, the support block is set on both sides of the bottom of the cutting chamber, the support plate is set above the support block, and both sides of the support block are provided with clamping structures, and the clamping structure is located on the same line as the inlet and outlet Above; the power transmission chamber is equipped with a discharge structure, a transmission structure and a feed structure. After realizing the clamping and cutting of the pipe material, the present invention can realize the functions of automatic circulation of pipe material discharge, straightening and feeding, and has a high degree of automation.

Owner:宁波隆锐机械制造有限公司

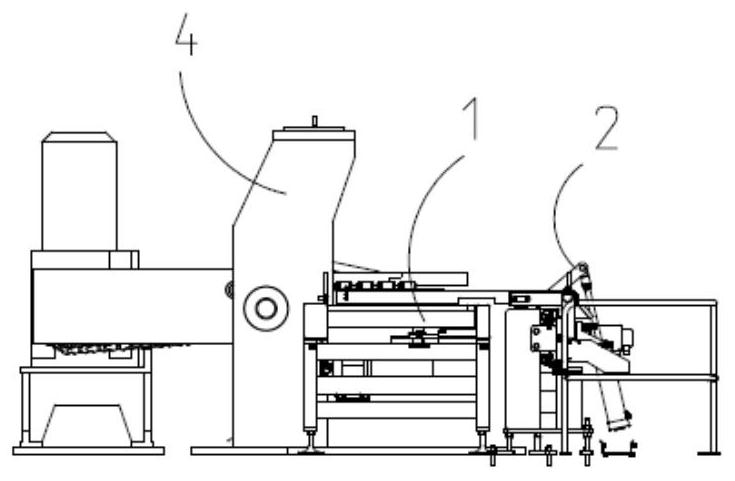

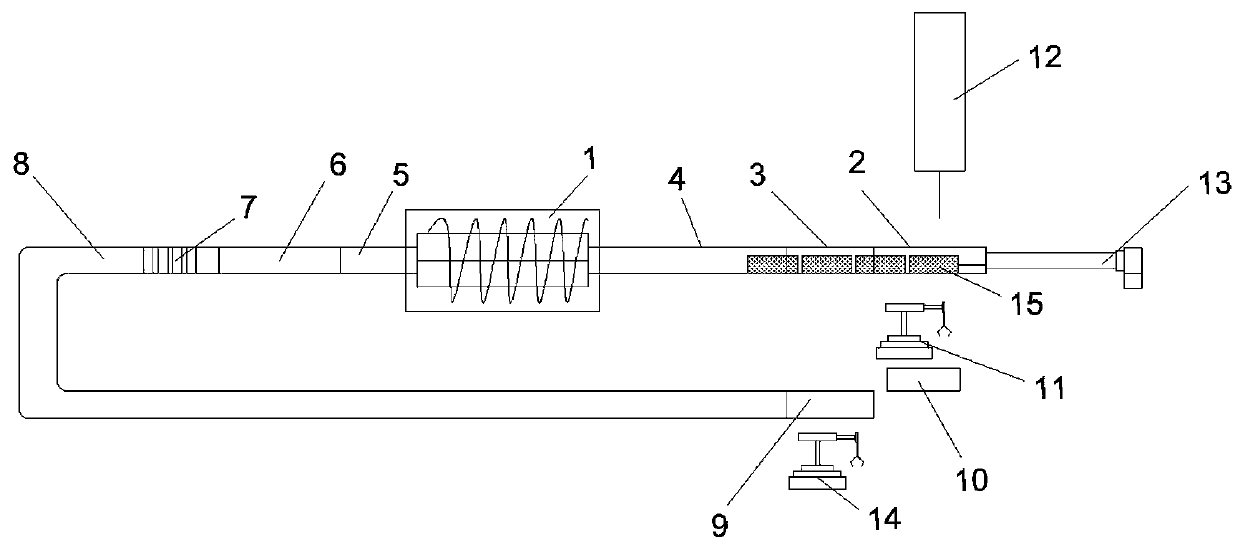

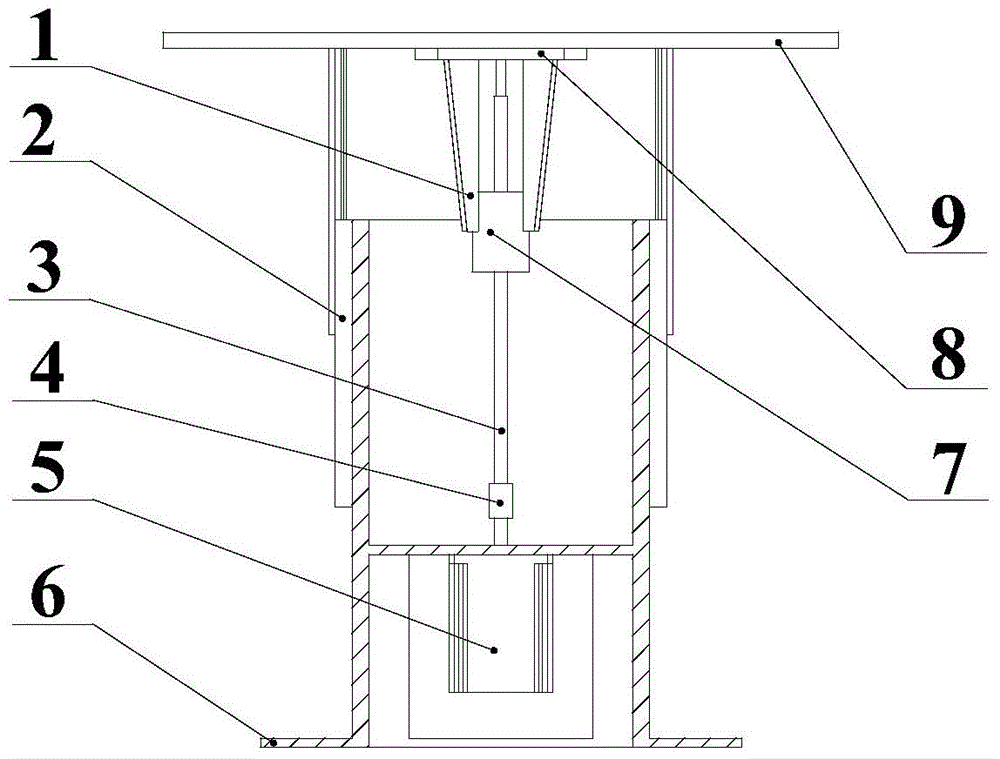

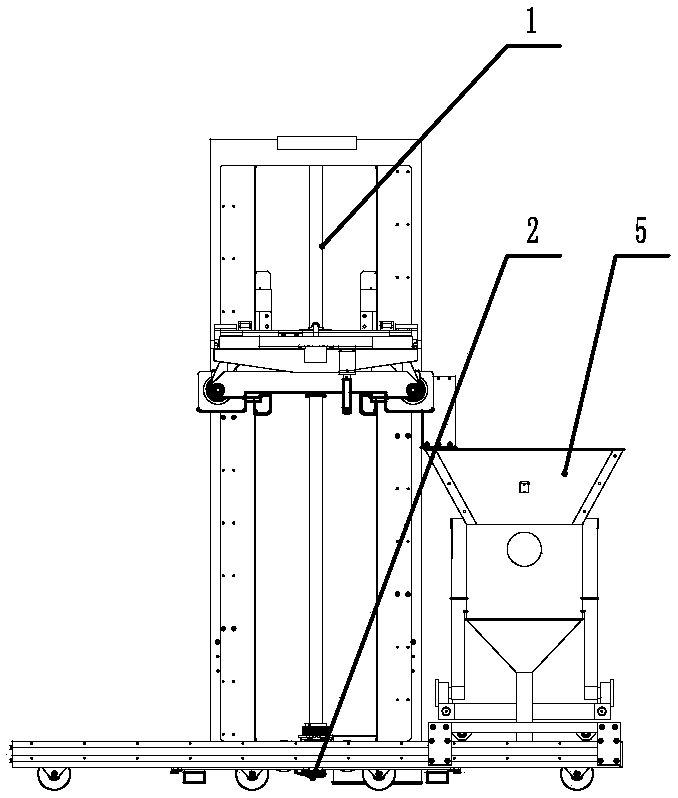

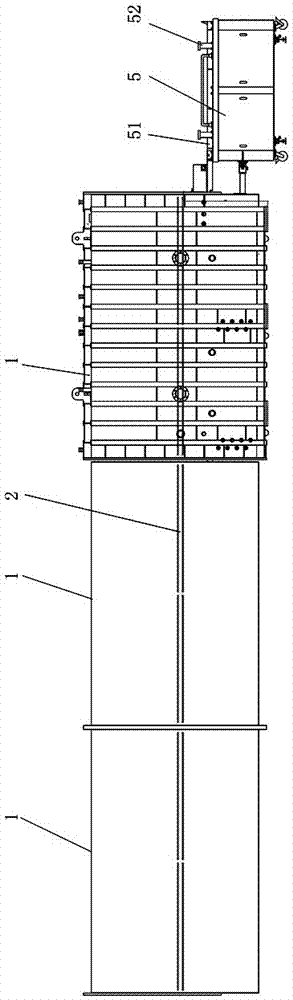

Automatic feeding and discharging device for graphite purification furnace

PendingCN110745821AAchieve cycleRealize automatic feeding and dischargingCarbon compoundsProcess engineeringGraphite

The invention discloses an automatic feeding and discharging device for a graphite purification furnace. A feeding table, a vacuum cabin and a feeding platform are sequentially arranged at the inlet side of the graphite purification furnace in the furnace inlet direction; a discharging platform, a cooling cabin, a conveying roller and a conveying belt are sequentially arranged at the outlet side of the graphite purification furnace in the furnace outlet direction; an unloading table is arranged at the tail end of the conveying belt; the unloading table and the feeding table are positioned in the same work region; a graphite boat transfer region is arranged between the unloading table and the feeding table; a graphite boat in the graphite boat transfer region is put on the feeding table bya feeding mechanical hand; the graphite boat on the feeding table is pushed and conveyed to the furnace entering direction of the graphite purification furnace through a boat pushing device, so that the graphite boat sequentially passes through the vacuum cabin, the feeding platform, the graphite purification furnace, the discharging platform, the cooling cabin, the conveying roller, the conveyingbelt and the unloading table; an unloading mechanical hand is arranged at one side of the unloading table; the graphite boat arranged on the unloading table is put in the graphite boat transfer region through the unloading mechanical hand; the automatic graphite feeding and discharging is realized; and the work efficiency is improved.

Owner:凯盛石墨碳材料有限公司

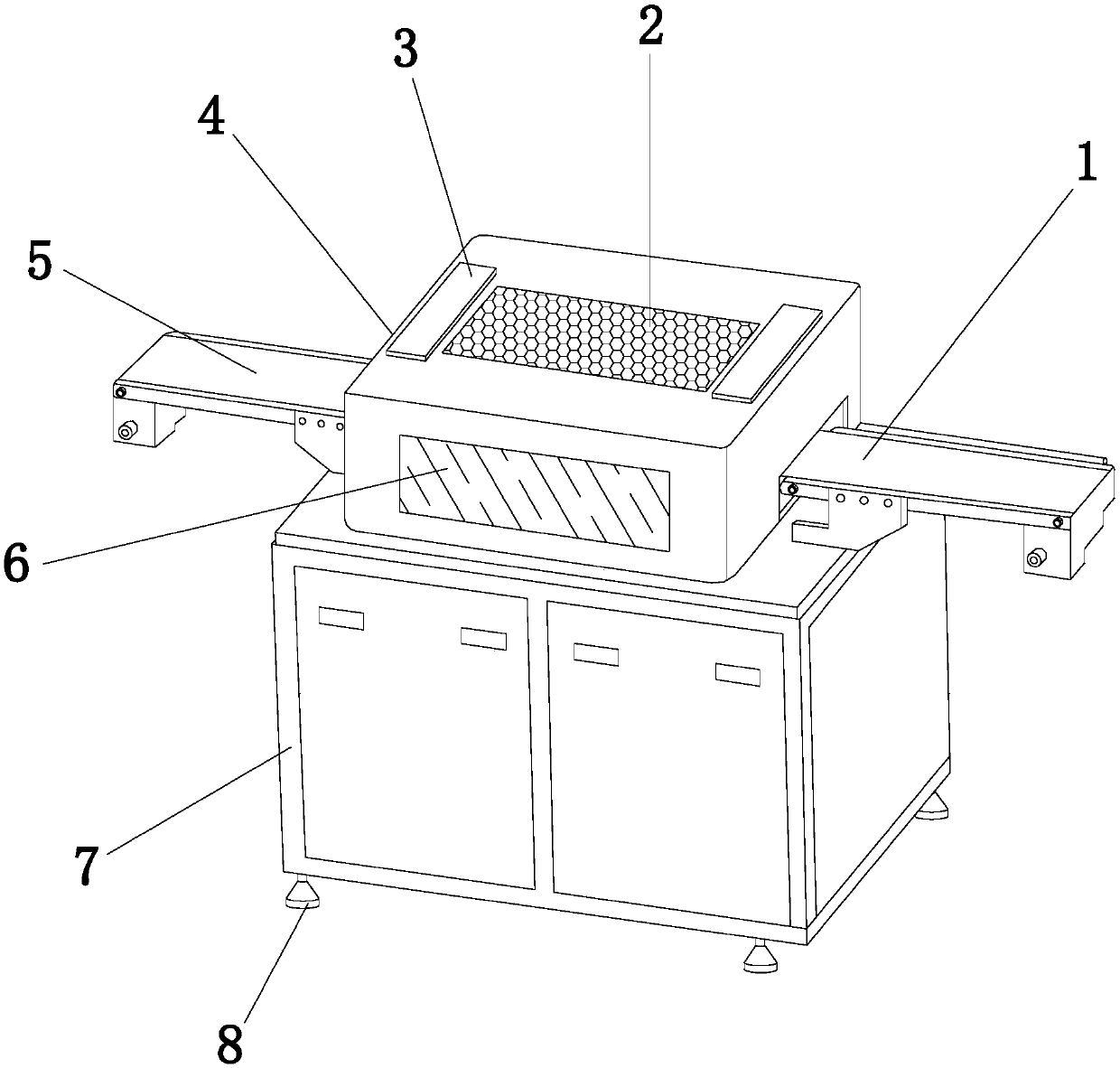

Rubber coating machine for tab

InactiveCN108115882ARealize automatic feeding and dischargingAchieve double-sided adhesiveDomestic articlesCoatingsEngineeringCoating

The invention discloses a rubber coating machine for a tab. The rubber coating machine structurally comprises a feeding conveying table, a heat dissipation net cover, a rubber injection movable cover,a rubber coating device, a discharging conveying table, an observing window, an operation table and damping ground legs, wherein the damping ground legs are vertically fixed on the operation table, the rubber coating device is arranged in the center of the top of the operation table and is buckled and fixed on the operation table, the observation window is formed in the front end of the rubber coating device and is in interference fit with the rubber coating device, the heat dissipation net cover is arranged in the center of the top of the rubber coating device and is buckled and fixed to a groove in the top of the rubber coating device. By utilizing the feeding conveying table and the discharging conveying table, automatic feeding and discharging can be realized; by utilizing an upper rubber coating mold and a lower rubber coating mold which are arranged in the rubber coating device, the rubber coating of two surfaces of the tab of a lithium battery can be realized, and rubber coating slurry can be continuously and steadily conveyed through the synchronization of rubber coating and mold pressing, so that the quality and production efficiency of a product can be improved.

Owner:梁叶青

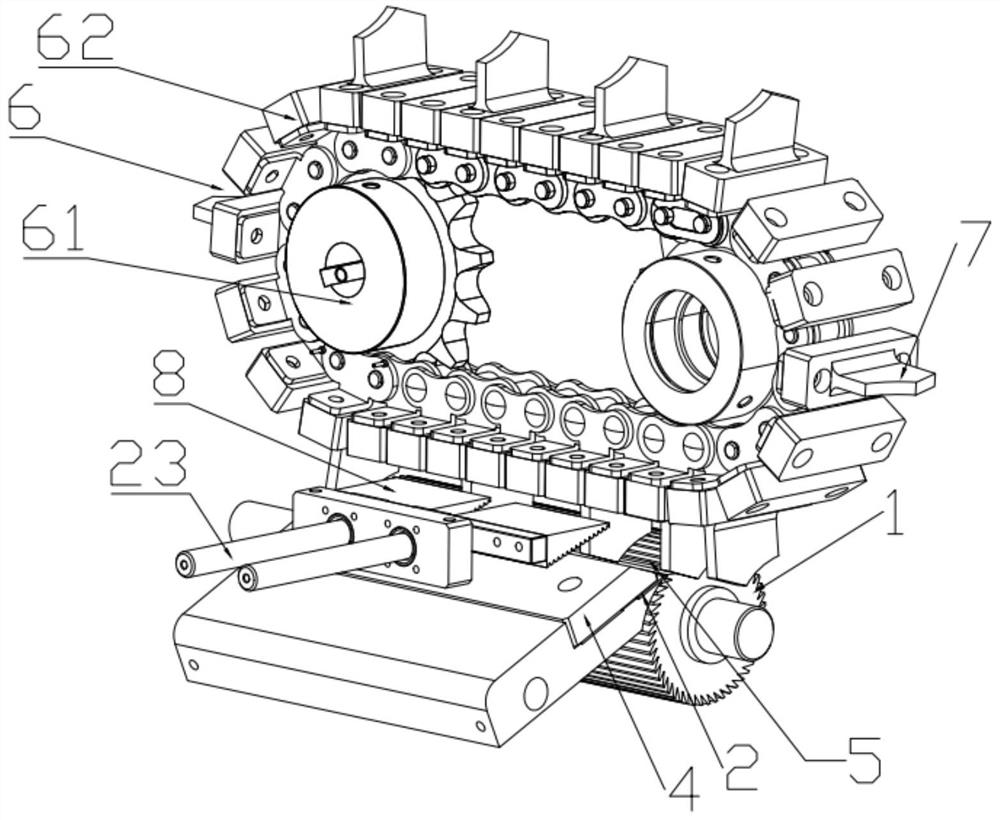

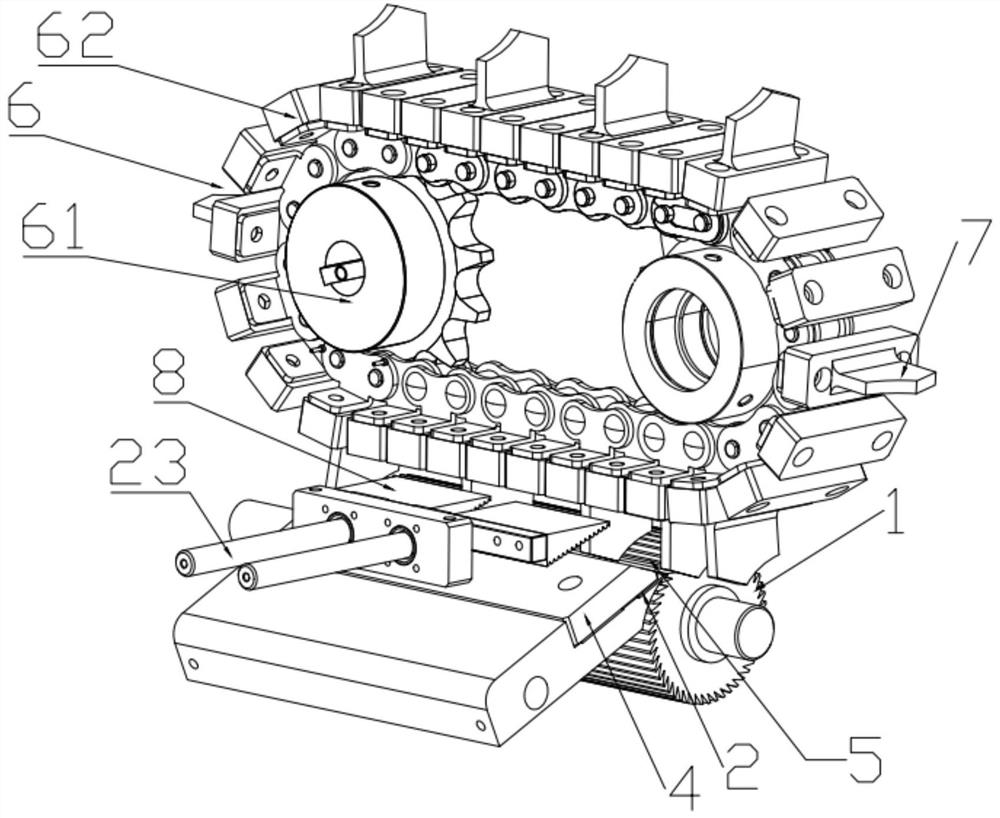

Multi-drive heart-shaped oil removing device

ActiveCN114271308AReduce the cost of the whole machineHigh degree of automationPoultry processingElectric machineryDrive motor

The invention provides a multi-drive chicken heart oil removing device which comprises a driving motor, an oil removing assembly, a bulldozing assembly and a conveying assembly, and a storage cavity used for temporarily storing chicken hearts is formed in the oil removing assembly; the output end of the driving motor is connected with the conveying assembly through a first transmission assembly and connected with the bulldozing assembly through a second transmission assembly, and the first transmission assembly and the second transmission assembly are asynchronously started, so that the conveying assembly stops running after the bulldozing assembly enters the storage cavity, or the bulldozing assembly does not enter the storage cavity when the conveying assembly pushes the heart-shaped part; that is to say, the processes of conveying and bulldozing the heart-shaped parts by the two complete machines can be completed through a single power source, the cost of the complete machines is reduced, and only one driving motor needs to be replaced when problems occur.

Owner:朗易智能科技(天津)有限公司

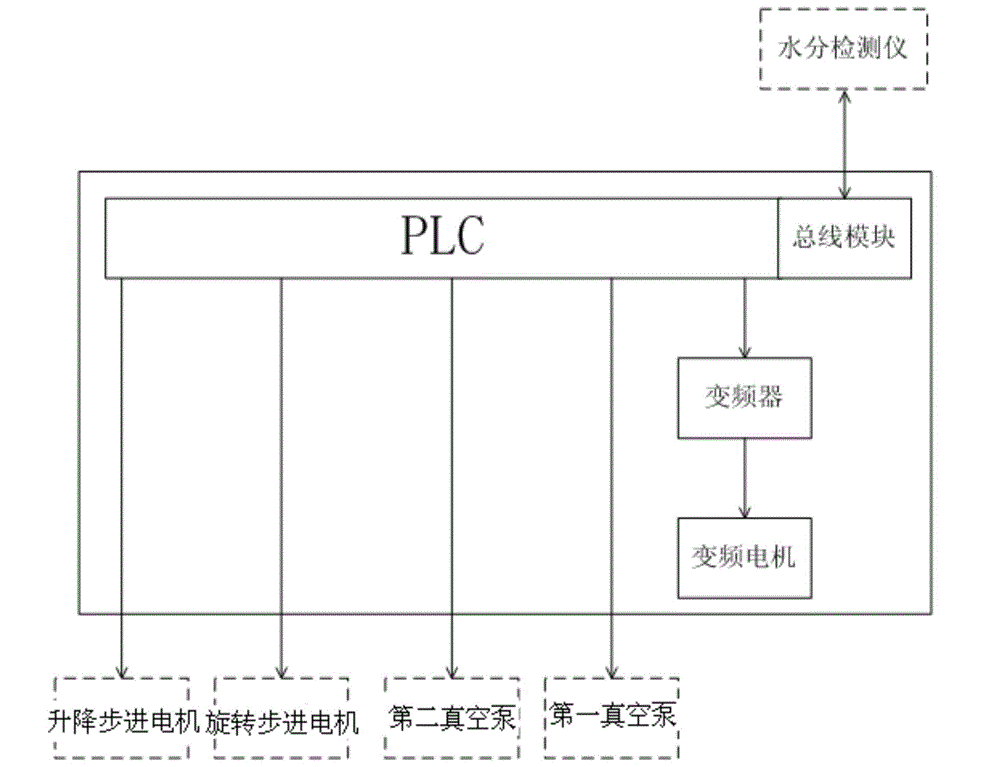

Fodder moisture detection control system

InactiveCN103615882BRealize automatic feeding and dischargingRealize closed-loop controlDrying solid materialsAutomatic controlControl system

A fodder moisture detection control system comprises a substrate, a lifting mechanism, a rotating mechanism, a moisture detector and a waste barrel, wherein the lifting mechanism comprises a lifting driving part; the rotating mechanism comprises a rotating driving part and a rotating frame, the rotating driving part is fixed to a supporting platform, the rotating frame is provided with a fodder sucking pipe, one end of the fodder sucking pipe is provided with a fodder sucking disc, and the other end of the fodder sucking pipe is provided with a discharging disc which is communicated with a vacuum pump. When the rotating frame is located in a first working position, fodder at vacuum negative pressure reaches the moisture detector through the fodder sucking pipe from a fodder conveying belt, when the rotating frame is located in a second working position, the fodder at the vacuum negative pressure reaches the waste barrel through the fodder sucking pipe from the moisture detector, the lifting mechanism and the rotating mechanism are matched so that rotating frame can reach the second working position form the first working position, the lifting mechanism and the rotating mechanism are controlled by a controller, the moisture detector is connected with the controller, and the controller controls rotation speed of a fodder conveying belt motor. The fodder moisture detection control system has the advantages of being capable of accurately measuring and automatically controlling the moisture content of the fodder.

Owner:ZHEJIANG UNIV

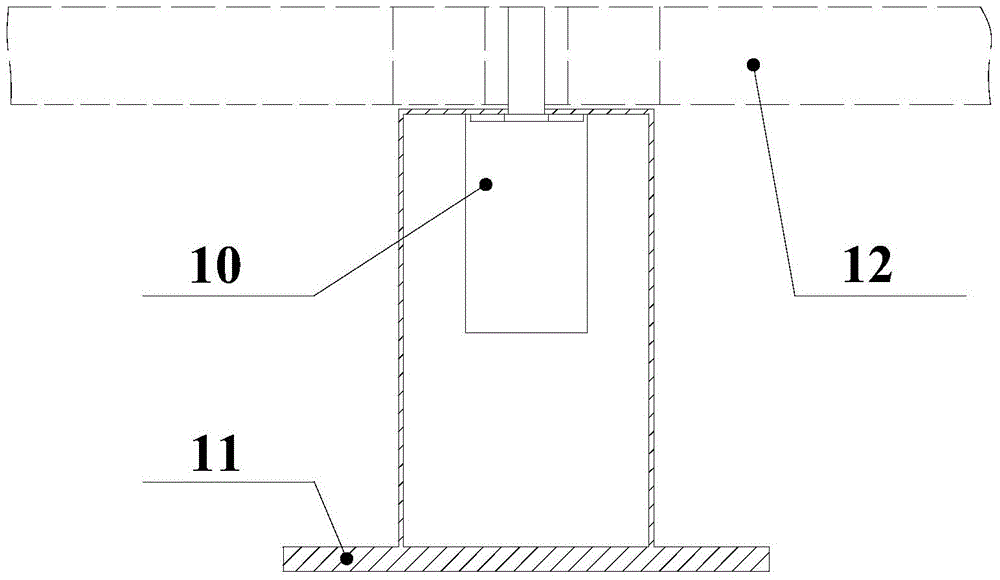

Assembled methane tank capable of automatic feeding and discharging

InactiveCN101538526AEasy to buildRealize automatic feeding and dischargingGas production bioreactorsWaste based fuelEngineeringMethane

The invention discloses an assembled methane tank capable of automatic feeding and discharging, which belongs to a household methane tank and mainly solves construction troubles and automatic feeding of the methane tank. The assembled methane tank has a structure that: a tank body of the assembled methane tank is a spherical shell prefabricated by using a resin material on the ground; the top of the spherical shell is connected with a feeding and discharging combined pipeline; a lower opening of the feeding and discharging combined pipeline extends to be under the liquid surface of the tank; upper openings of the pipeline is set into two heights; the high upper opening is a feeding opening, and the low upper opening is a discharging opening; and a slug discharge pipe is inserted into the discharging opening and extends to the bottom of the tank body. The spherical shell and the feeding and discharging combined pipeline can be processed in advance before construction and assembled on site, so the construction is convenient; in addition, automatic feeding and discharging can be achieved, the troubles of manual regular feeding and pond cleaning can be eliminated; and as a rotational flow wall is arranged, methane materials can automatic stir in the tank.

Owner:陈衍水

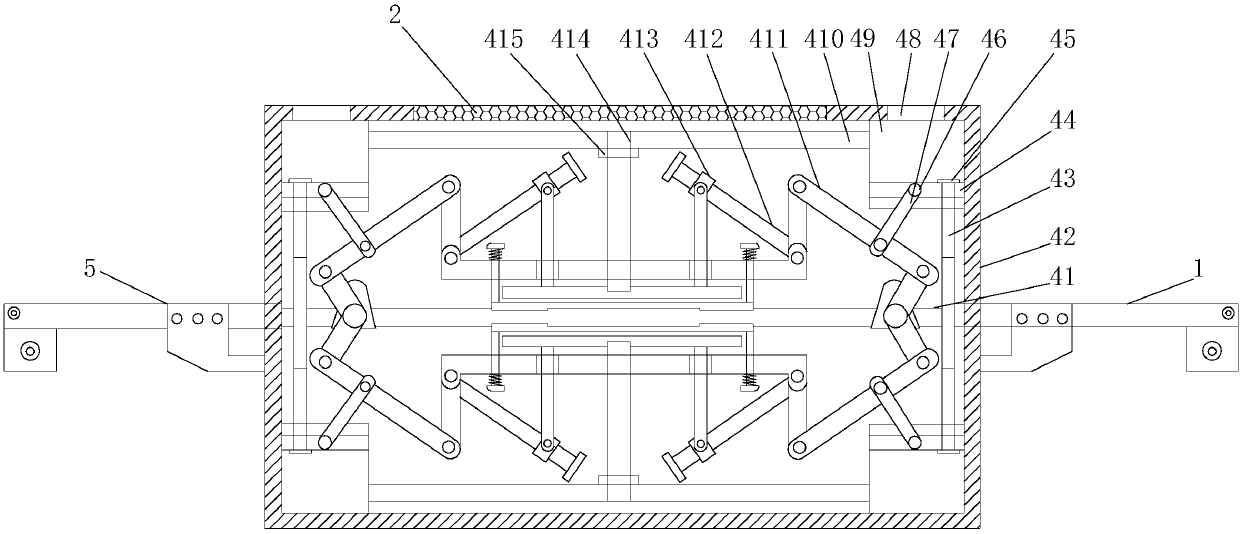

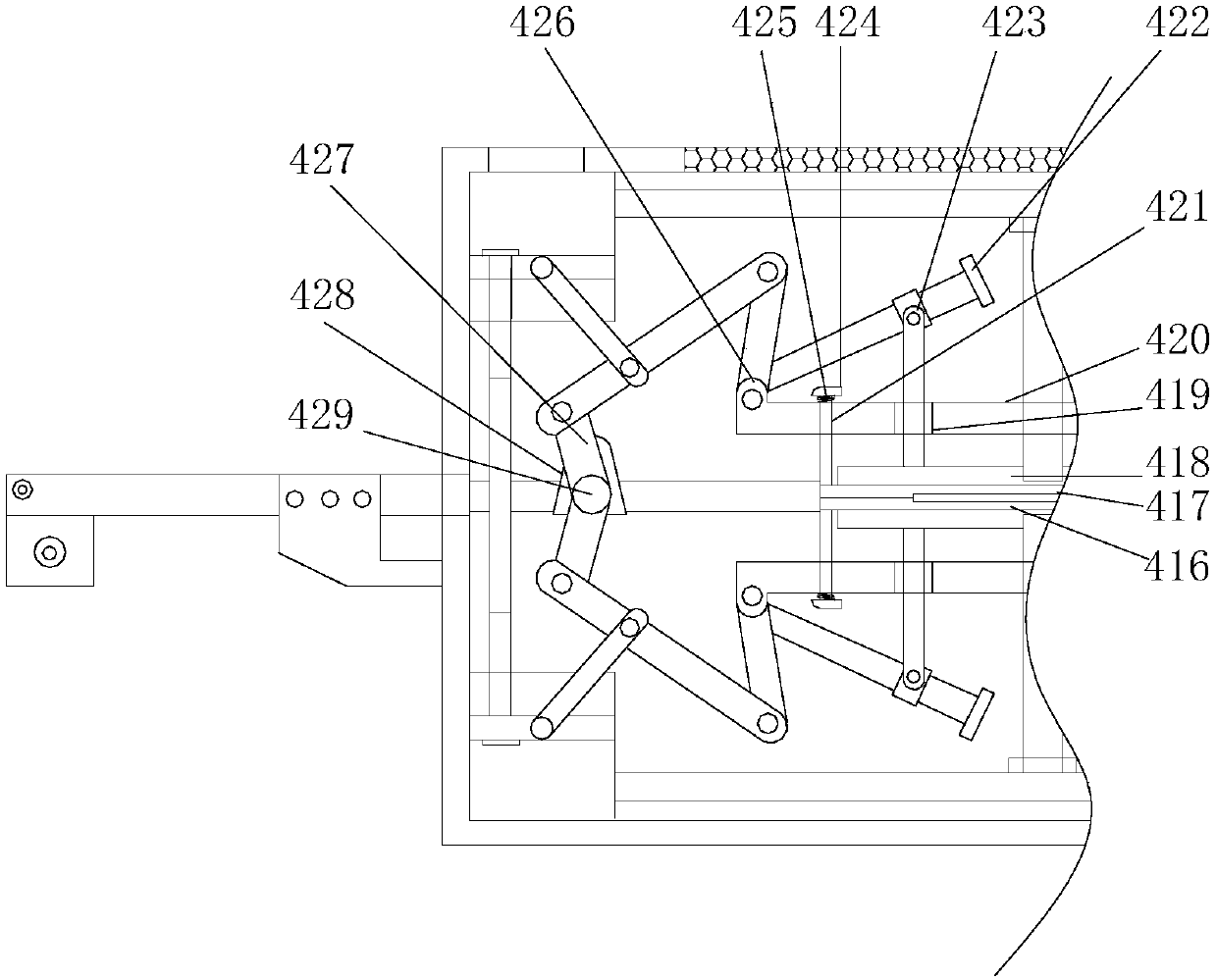

A fully automatic thermocompression forming device for multi-layer composite epoxy glass fiber board

The invention discloses a fully automatic hot-press forming device for multi-layer composite epoxy glass fiber boards, which comprises a spinning assembly and a tray on which the composite boards to be hot-pressed are placed, the spinning assembly has a rotary drive, and the spinning The assembly applies heat while applying pressure to the upper surface of the composite sheet. The active action of the spinning assembly is only one rotary motion. A roller is set on the upper surface of the composite sheet through multiple connecting rods. The roller presses the upper surface of the composite sheet and rolls and applies pressure to maintain the pressed state. Then the spinning assembly can also be carried out. Heat generation, heat the composite board at the contact position on the upper surface of the other composite boards, the glued material inside the composite board will glue the composite boards into one, at the same time of gluing, the surface of the composite board can also be pre-set with a layer of release film, the hot pressing process Attached together to the composite sheet.

Owner:广东纵胜新材料股份有限公司

Full-automatic hot press molding device for multi-layer composite epoxy glass fiber plate

ActiveCN113071109ASimple drive structureWide range of pressing lengthsFlat articlesGlass fiberSpinning

The invention discloses a full-automatic hot press forming device for a multi-layer composite epoxy glass fiber plate. The full-automatic hot press forming device comprises a spinning assembly and a tray; the composite plate to be subjected to hot-press forming is placed on the tray; the spinning assembly is provided with a rotary drive; the spinning assembly heats the upper surface of the composite plate while applying pressure to the upper surface of the composite plate; only one rotary motion is adopted in the active action of the spinning assembly; a roller is arranged on the upper surface of the composite plate through a plurality of connecting rods; the roller presses the upper surface of the composite plate and conducts rolling pressure application to keep a press-fit state; then the spinning assembly can further conduct heating to heat the other contact positions of the upper surface of the composite plate; the composite plate is glued into a whole through a gluing material in the composite plate; a layer of release film can be further arranged on the surface of the composite plate in advance during gluing; and the release film is attached to the composite plate in the hot pressing process.

Owner:HUIZHOU ZONGSHENG ELECTRONICS MATERIAL CO LTD

Turnover equipment capable of turning over by 180 degrees

InactiveCN114148723ARealize automatic feeding and dischargingImprove efficiencyConveyor partsRoller-waysDrive shaftElectric machinery

Owner:安曼德智能科技(江苏)有限公司

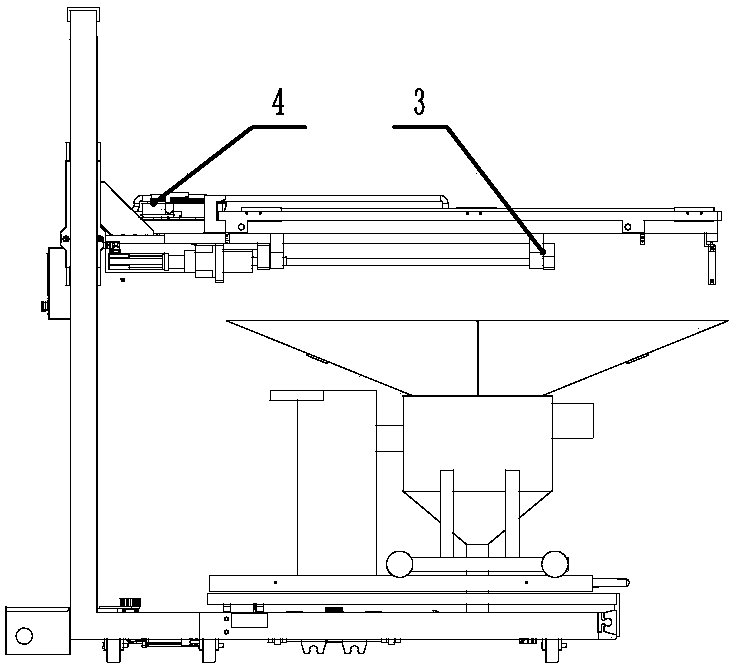

Raw material drug freeze-drying automatic feeding and discharging system

ActiveCN106219211BRealize automatic feeding and dischargingSolve the problem that manual operation is easy to contaminate medicinesConveyor partsFreeze-dryingDrug pollution

Owner:SHINVA MEDICAL INSTR CO LTD

Centrifugal soil screening device for soil restoration

ActiveCN108465637BIncrease centrifugal forceMost of the gravel is in the upper radius and the centrifugal force is largerGas current separationSoil scienceSoil remediation

The invention discloses a centrifugal soil screening device for soil remediation. The centrifugal soil screening device comprises a driving device, a supporting device and a screen, wherein the driving device is arranged on the supporting device, the screen is in a funnel structure shape with a larger upper part and a smaller lower part, and the driving device is connected to the screen in a driving mode to enable the screen to rotate around the axis. The centrifugal soil screening device for soil remediation has the advantages that automatic feeding, discharging and gravel screening can be realized, labor can be saved, meanwhile, soil accumulation can be effectively prevented, and a better screening effect can be achieved.

Owner:GUANGZHOU FIRST MUNICIPAL ENG CO LTD

a freeze dryer

ActiveCN105091507BRealize automatic feeding and dischargingCompact structureDrying solid materials without heatFreeze-dryingEngineering

The invention discloses a freeze-drying machine, which comprises a freeze-drying box, in which a material transfer bottom rail is arranged along the feeding direction, and at least one side of the material transfer bottom rail is provided with a freeze-drying plate unit, so that The freeze dryer also includes a mobile trolley and a material transfer frame that can be docked with the mobile trolley. The mobile trolley can move on the material transfer bottom rail and drive the material transfer frame to dock with the freeze-dried ply unit. The invention has the advantages of high degree of automation, compact structure of the whole machine and high production efficiency.

Owner:TRUKING TECH LTD

Chicken heart oil removing device and chicken heart oil removing method

ActiveCN114271307AComplete shapeHigh degree of automationConveyorsPoultry processingBiologyPetroleum engineering

The invention provides a chicken heart oil removing device which comprises an oil removing assembly and a bulldozing assembly, the oil removing assembly comprises an oil removing round roller cutter capable of rotating in the axial direction and an oil removing slice cutter relatively static, the oil removing slice cutter inclines in the radial direction relative to the oil removing round roller cutter, and a gap for chicken oil to pass through is reserved between the oil removing round roller cutter and the oil removing slice cutter. A limiting plate is arranged above the oil removing piece cutter, a storage cavity for temporarily storing the chicken hearts is formed between the limiting plate and the oil removing round roller cutter, and the bulldozing assembly can reciprocate along the storage cavity and is used for pushing the chicken hearts down into the storage cavity; under the action of centrifugal force, the film-shaped chicken oil is continuously contacted with the cutting edges of the oil-removing round roller cutter and the oil-removing slice cutter, so that the chicken oil is stripped from the chicken heart; compared with the prior art, the automation degree is high, the shape of the chicken heart after oil removal is complete, chicken oil is removed while the chicken heart is turned over, and the production efficiency is greatly improved.

Owner:朗易智能科技(天津)有限公司

An automatic feeding and discharging deoiling machine

ActiveCN104399599BRealize automatic feeding and dischargingExtension of timeRotary centrifugesEngineeringMechanical engineering

The invention discloses an automatic blanking discharging de-oiling machine which comprises a rotating drum, a rotating shaft, a power device, a supporting shaft, a feeding hopper and a frame, wherein the rotating drum is connected with the rotating shaft; the rotating shaft is connected with the power device; the power device is fixed on the frame; a plurality of oil draining holes are uniformly distributed in a drum wall of the rotating drum; a central pillar is arranged in the rotating drum; a spiral baffle is arranged on the central pillar; a blanking channel is arranged in the supporting shaft; a blanking hole is arranged in a side wall of an end part of the blanking channel in the rotating drum; the interior of the rotating drum and the blanking channel are communicated with each other by the blanking hole; the other end of the blanking channel is connected with the feeding hopper; a discharging door is arranged on the end part of one side, which is connected with the rotating shaft, of the rotating drum; a protecting fence is arranged on the side, connected with the rotating shaft, of the rotating drum; an oil baffle cover is arranged on the outer periphery of the rotating drum; an oil collecting slot is arranged in the frame under the oil baffle cover. According to the automatic blanking discharging de-oiling machine, the blanking channel and the feeding hopper are connected with each other and the discharging door is arranged on the rotating drum, so that the automatic blanking and discharging of the de-oiling machine are realized, the de-oiling process is continuously performed and the de-oiling efficiency is increased.

Owner:ZHEJIANG RONNIE PRECISION MACHINE

A biochemical detector

ActiveCN108717113BRealize automatic feeding and dischargingQuick checkBiological testingEngineeringTest tube

Owner:山东华航医学科技有限公司

Treatment equipment for inclined surface of metal material

InactiveCN112223069AEasy to collectImprove applicabilityGrinding carriagesGrinding drivesMetallic materialsMaterials science

The invention discloses treatment equipment for an inclined surface of a metal material, in particular to the technical field of surface treatment of metal materials. The equipment comprises a frame body and a base, wherein support legs are fixedly connected to the bottom of the base; the frame body is fixedly connected to the top of the base; lifting structures are arranged on the two sides of the outer part of the frame body; a cleaning structure is arranged on the top of the base; a telescopic mechanism is arranged in the middle of the two sides of the interior of the frame body; and a feeding mechanism is fixedly connected to the bottom ends of the two sides of the interior of the frame body. According to the treatment equipment for the inclined surface of the metal material disclosedby the invention, through arrangement of a first lifting screw rod and a second lifting screw rod on a support rack, adjusting handwheels which are arranged on the upper parts of the first lifting screw rod and the second lifting screw rod are rotated, buffering rollers which are arranged at the lower end of the first lifting screw rod and the lifting lower end of the second lifting screw rod areseparately controlled to jack up an abrasive belt downwards, and the different lifting height of the first lifting screw rod and the second lifting screw rod can be adjusted, and thus, an inclinationangle of the abrasive belt is controlled, and the aim of grinding the inclined surface of materials is fulfilled.

Owner:蚌埠知博自动化技术开发有限公司

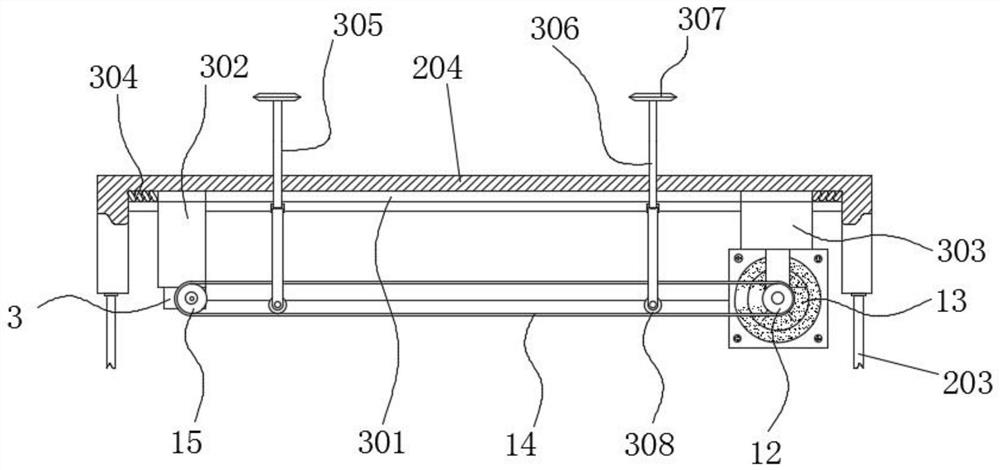

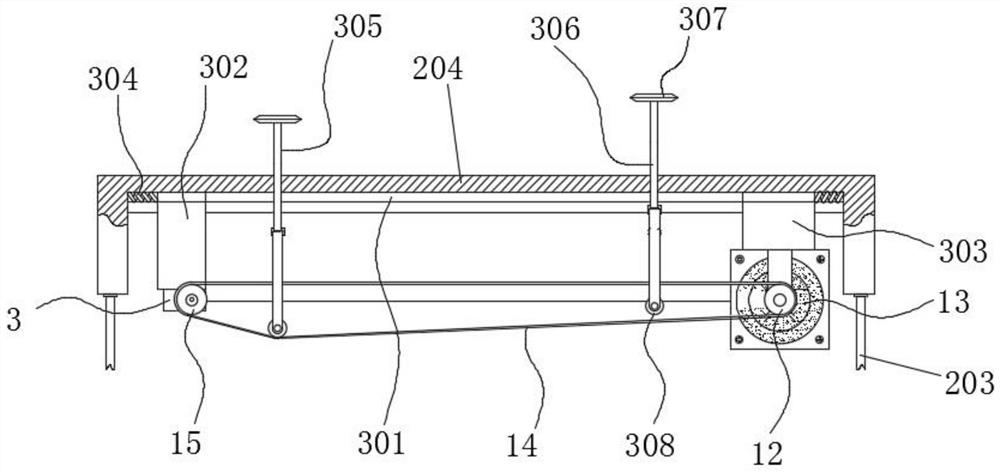

Corner nailing machine

PendingCN107972138ASatisfy automated productionIncrease productivityStapling toolsNailing toolsTransfer mechanismLeather belt

The invention provides a corner nailing machine and relates to corner nailing machinery. The corner nailing machine comprises a working face and a nail outlet device, wherein the nail outlet device isused for nailing a to-be-machined part positioned on the working face; an automatic feeding and discharging mechanism is arranged on the working face and comprises a belt transfer mechanism, push plate feeding mechanisms and a positioning mechanism; the push plate feeding mechanisms are perpendicular to a belt transfer direction and are respectively arranged on two sides of the belt transfer mechanism; the positioning mechanism is arranged on the working face; two positioning baffles are arranged on the belt transfer mechanism and respectively arranged on the working face in a sliding manner;the push plate feeding mechanisms are arranged between the two positioning baffles; and the positioning mechanism is arranged between the two push plate feeding mechanisms. The corner nailing machinedisclosed by the invention is capable of realizing automatic feeding and discharging and meeting automatic production needs and has high production efficiency.

Owner:南通嘉奇钣金科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com