Rubber coating machine for tab

A coating machine and pole lug technology, applied in the field of rubber coating machines, can solve the problems of unstable, unsmooth coating process of the polar lugs, and unsustainable conveying of the coating material, and achieve automatic feeding and discharging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

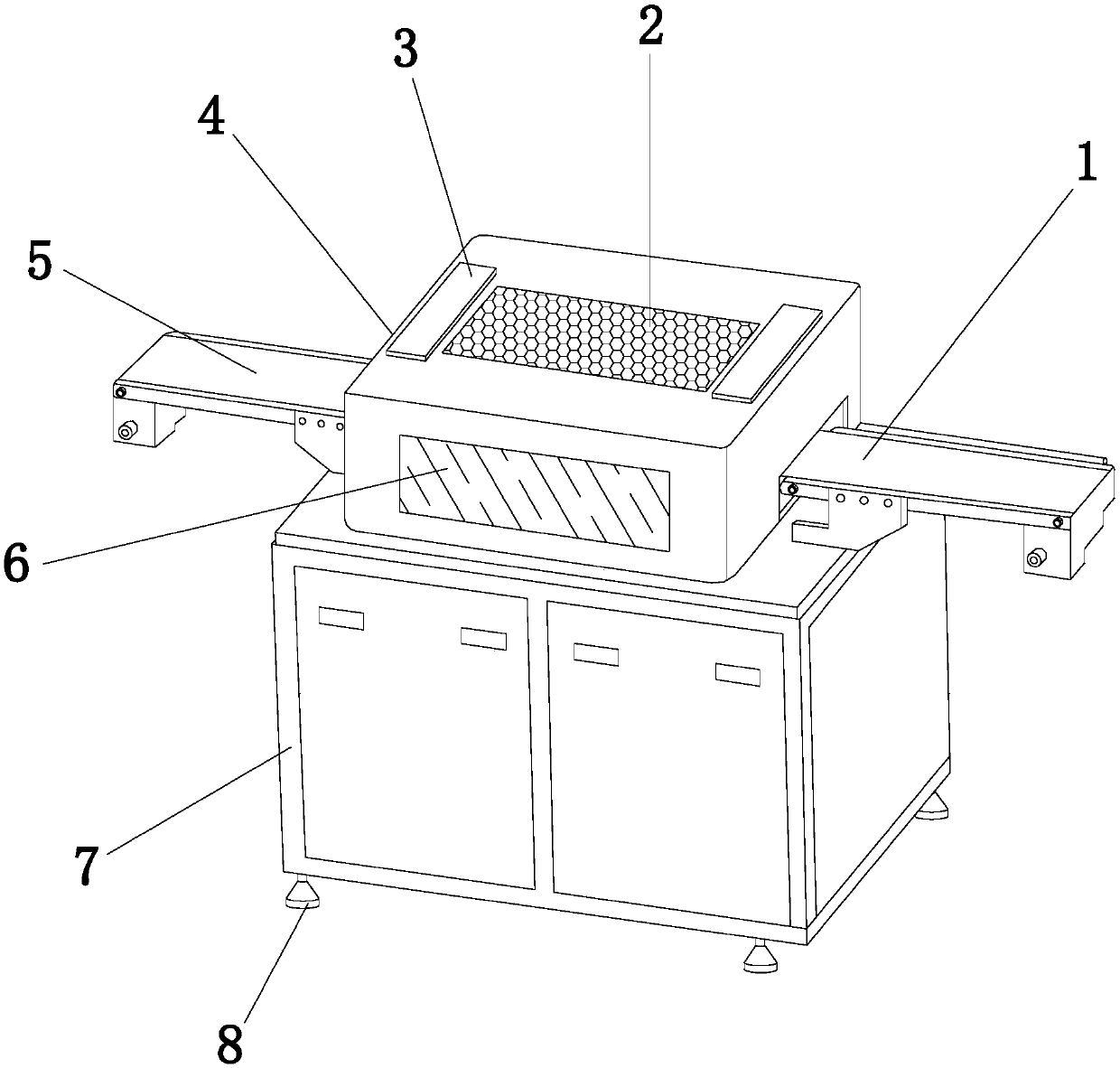

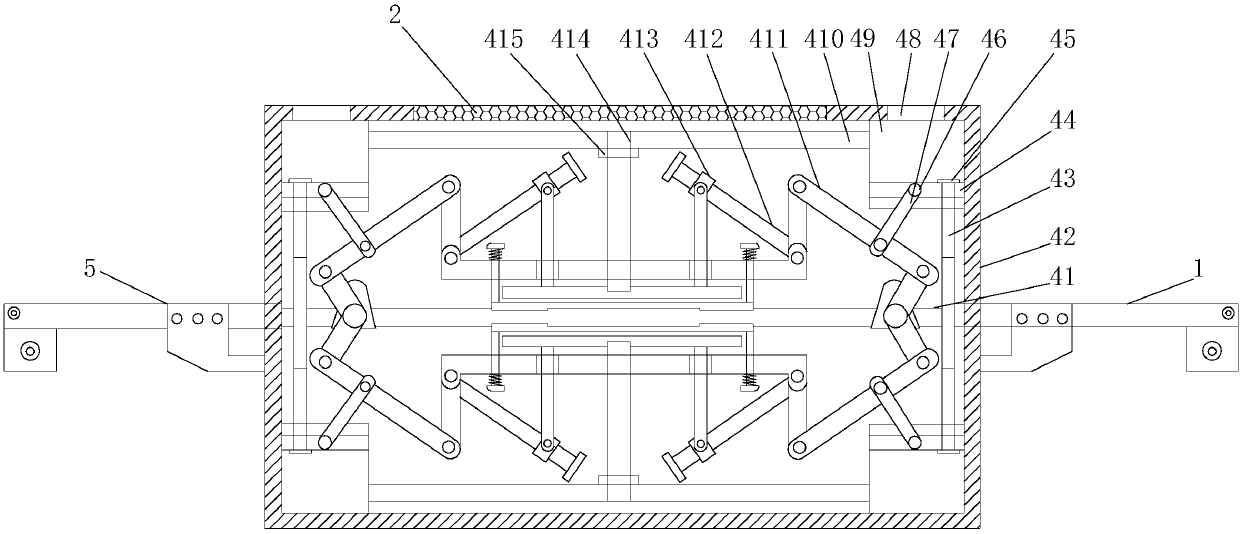

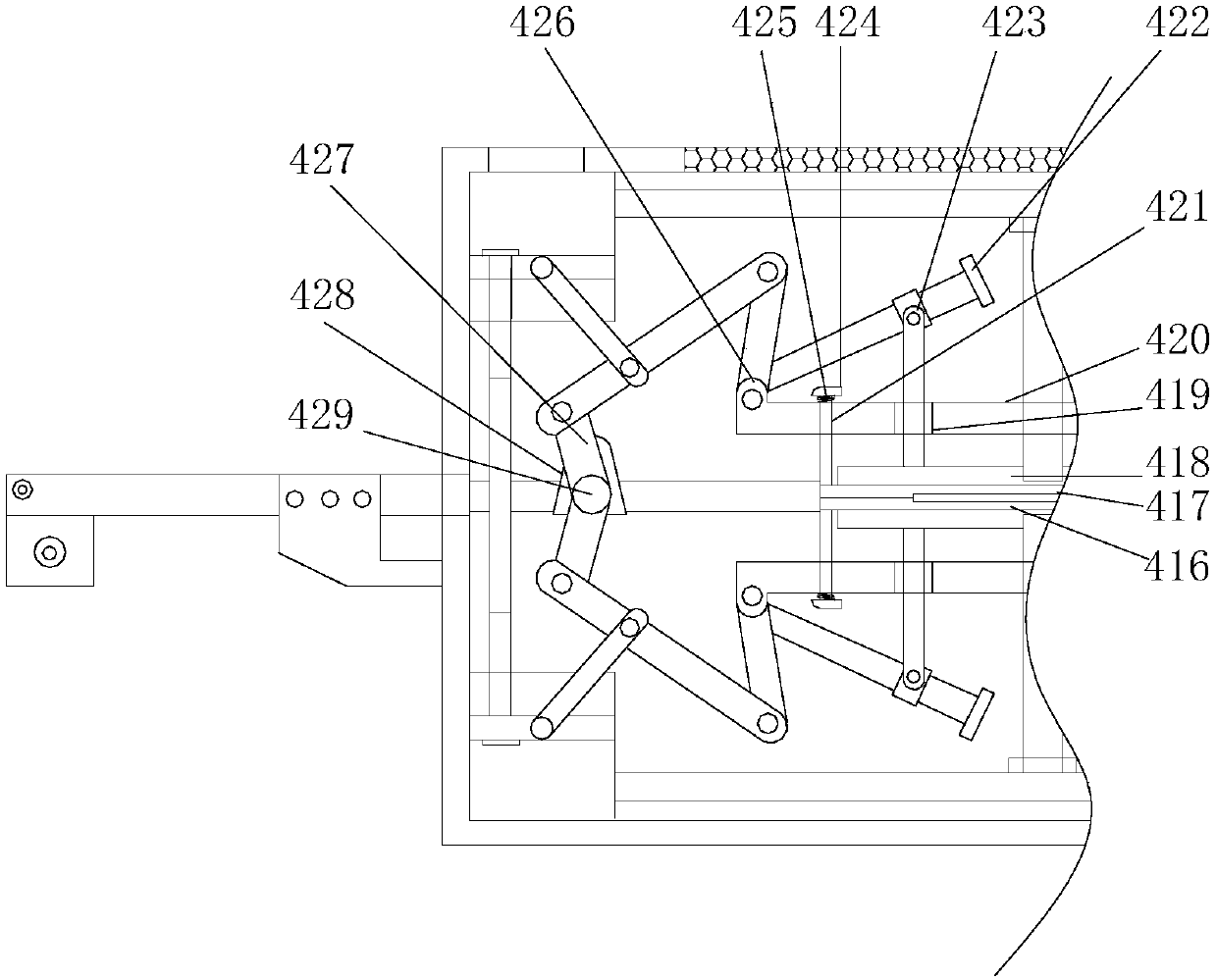

[0024] see Figure 1-Figure 4, the present invention provides a tab lug wrapping machine, the structure of which includes a feeding conveying platform 1, a heat dissipation net cover 2, a glue injection movable cover 3, a wrapping device 4, a discharge conveying platform 5, an observation window 6, and an operating console 7 , shock-absorbing feet 8, four shock-absorbing feet 8 are evenly spaced at the bottom of the operating table 7, and the shock-absorbing feet 8 are vertically fixed on the operating table 7, and the operating table 7 A glue-covering device 4 is provided at the center of the top, and the glue-covering device 4 is buckled and fixed on the console 7. An observation window 6 is provided at the front end of the glue-covering device 4, and the observation window 6 and the glue-covering device 4. The interference fit is adopted, and the heat dissipation net cover 2 is provided at the center of the top of the rubber coating device 4, and the heat dissipation net co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com