Automatic blanking discharging de-oiling machine

A technology of automatic cutting and deoiling machine, applied in the field of parts processing machinery and deoiling machine, can solve the problems of unfavorable production efficiency, restricting processing speed, slow deoiling speed, etc., to prevent oil droplets from splashing, reduce burden, The effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

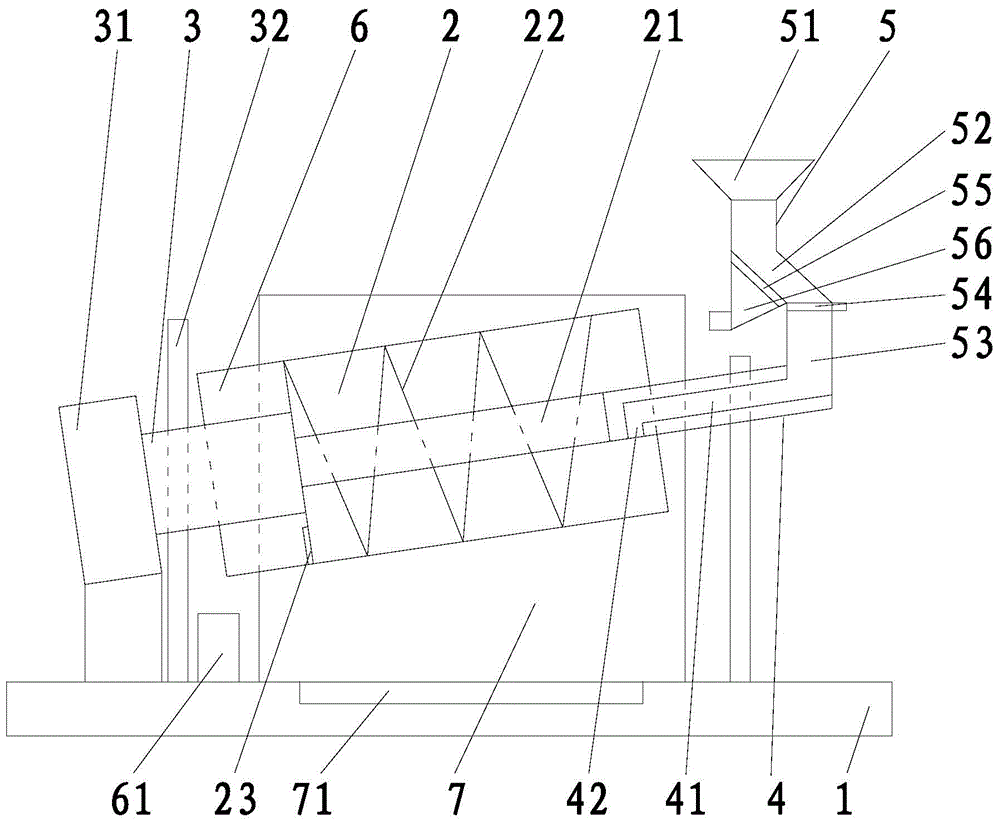

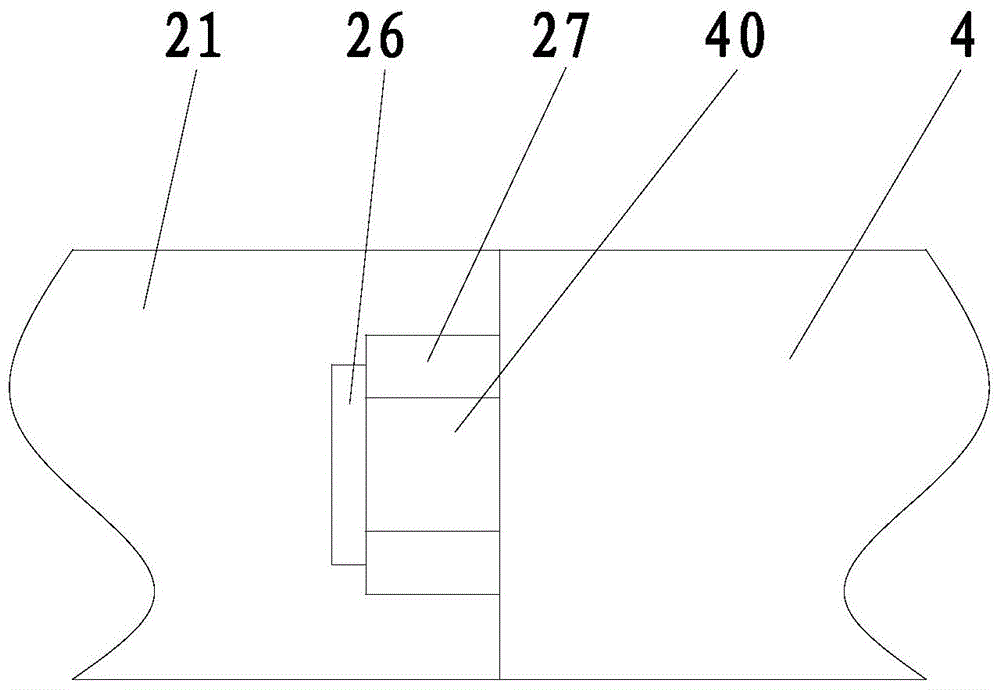

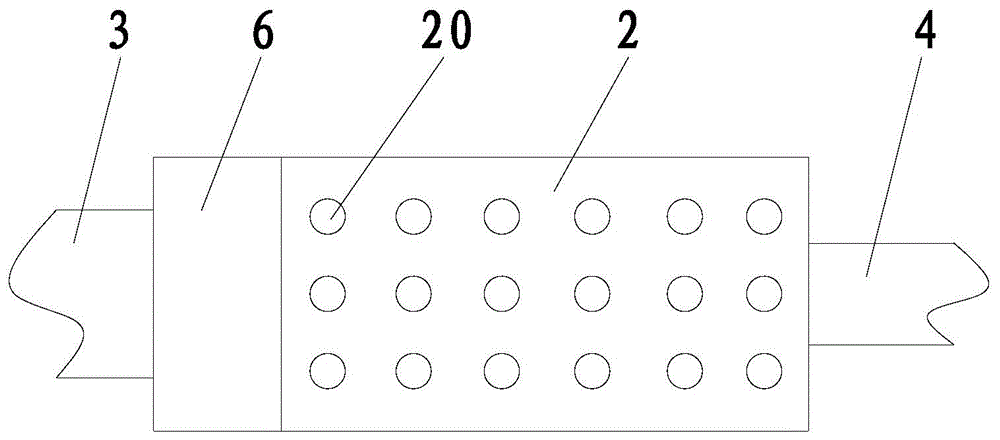

[0016] refer to figure 1 , figure 2 and image 3 , an automatic feeding and discharging deoiler of the present invention, comprising a rotating drum 2, a rotating shaft 3, a power unit 31, a support shaft 4, a feeding hopper 5, and a frame 1, the rotating drum 2 is connected to the rotating shaft 3, and the rotating shaft 3 is connected with the power device 31, and the power device 31 is fixed on the frame 1. A number of oil discharge holes 20 are evenly distributed on the wall of the drum 2. There is a central column 21 inside the drum 2, and there is a spiral on the central column 21. Baffle plate 22, the other end of the baffle plate 22 is in contact with the inner wall of the drum 2, one end of the central column 21 is fixed on the inner end of the drum 2, the other end has a stepped groove 26, and there is a main bearing 27 in the groove 26, so The support shaft 4 extends into the drum 2, and there is a boss 40 on the support shaft 4, and the boss 40 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com