Assembled methane tank capable of automatic feeding and discharging

A technology of feeding and discharging, assembly type, applied in waste fuel, gas production bioreactor, biochemical instrument, etc., can solve the problems of automatic discharging, troublesome construction of biogas pool, etc., and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

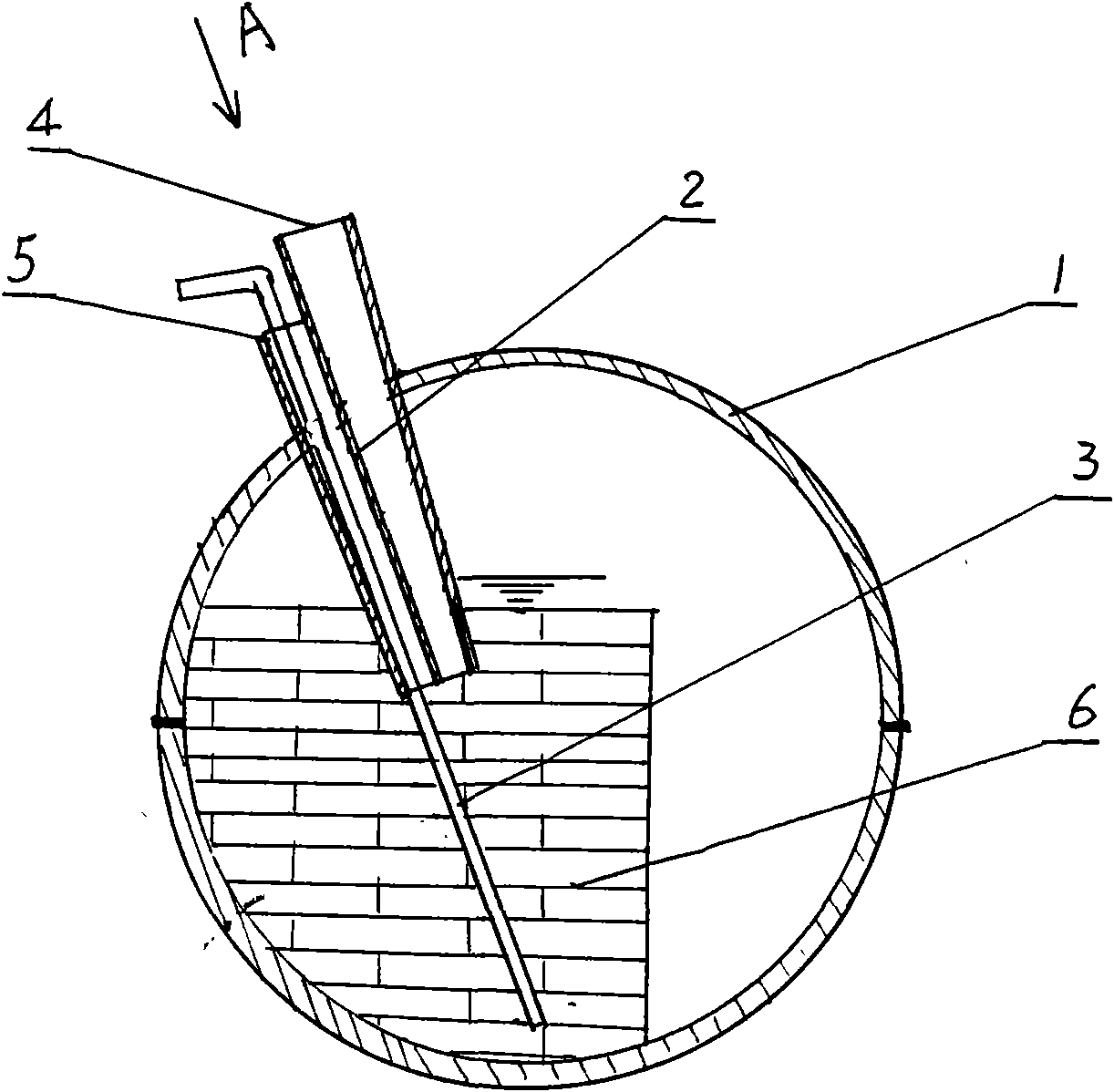

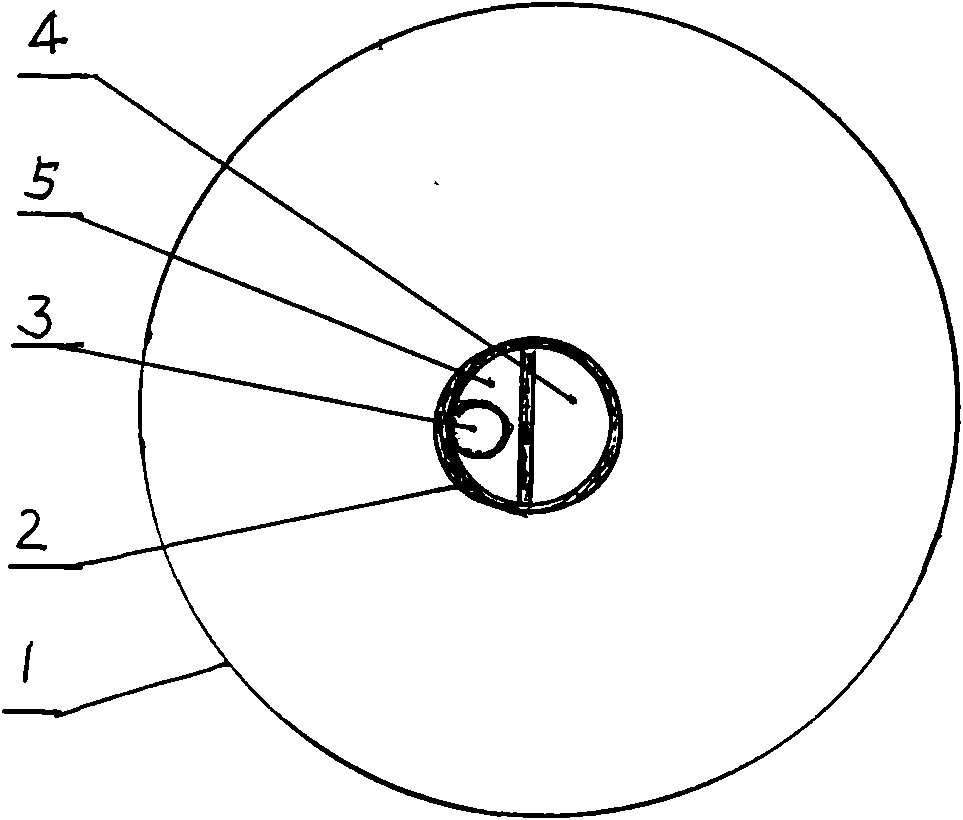

[0010] Examples of the present invention are figure 1 and figure 2 As shown, at first prefabricated spherical housing 1 with resin material as pool body on the ground. During prefabrication, the spherical shell 1 can be prefabricated into two hemispherical shells (or a quarter spherical shell), and on that spherical shell on the top surface, the inlet and outlet combined pipeline inlet is reserved. When installing, put two hemispherical shells (or four quarter spherical shells) together, insert the inlet and outlet combined pipeline 2 through the inlet of the combined pipeline and bond them firmly. The combined inlet and outlet pipeline 2 is a prefabricated resin material. The pipe is divided into two spaces by a partition and has a large upper mouth and a smaller lower mouth. The lower mouth of the pipe extends below the liquid level in the pool. The upper mouth of the pipe is set at two heights. The mouth with a low height is the discharge port 5, and a slag discharge pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com