Freeze drier

A freeze-drying machine and freeze-drying technology, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of small area of freeze-dried plates, unsuitable for mass production, and slow feeding speed. , to achieve the effect of compact structure, high production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

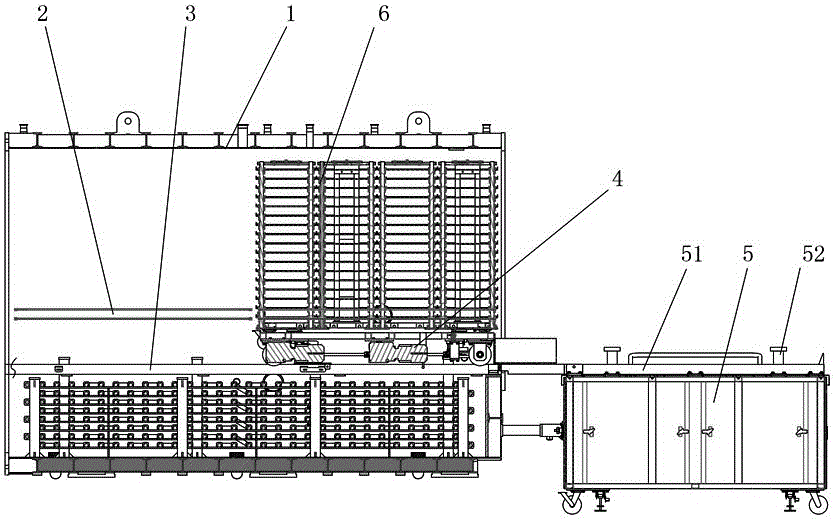

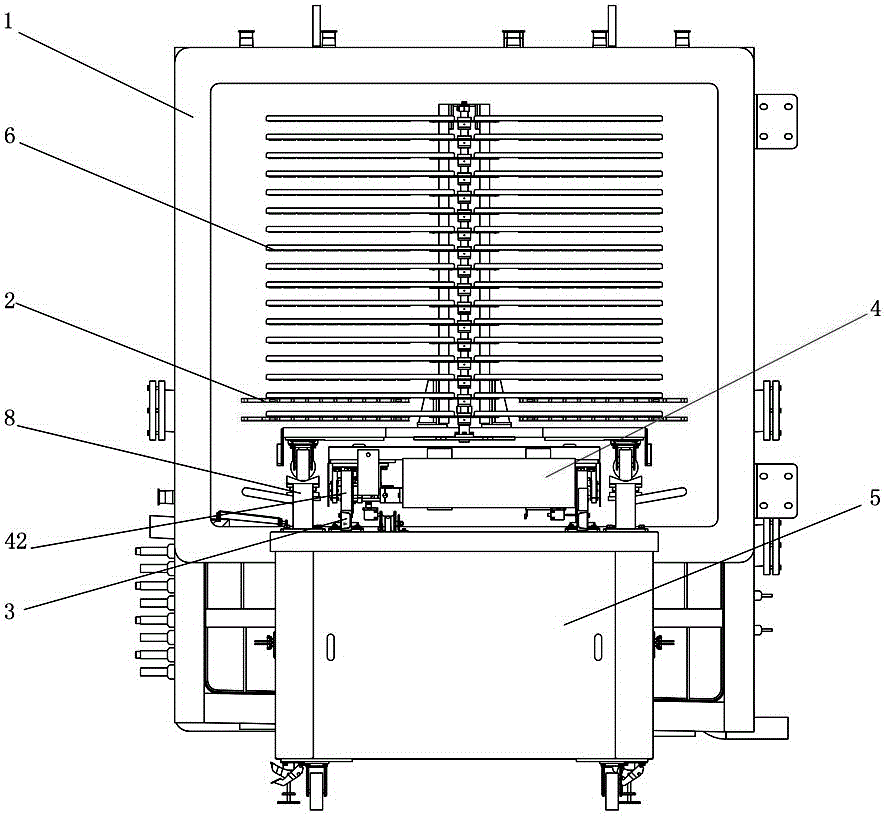

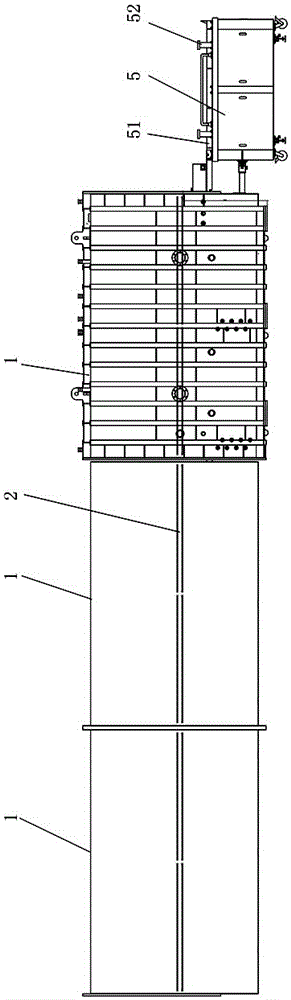

[0035] Figure 1 to Figure 12 An embodiment of the freeze dryer of the present invention is shown. The freeze dryer includes a freeze-drying box 1, and the freeze-drying box 1 is provided with a material transfer bottom rail 3 along the feeding direction, and at least one side of the material transfer bottom rail 3 A freeze-drying plate unit 2 is provided. The freeze dryer also includes a mobile trolley 4 and a material transfer frame 6 that can be docked with the mobile trolley 4. The mobile trolley 4 can move on the material transfer bottom rail 3 and drive the material transfer frame 6 and the freezer. Dry ply unit 2 butt. Before feeding, the material transfer rack 6 is transported to the inlet and outlet of the freeze-drying box 1, and the mobile trolley 4 moves on the material transfer bottom rail 3 in the freeze-drying box 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com