Aligned feeding device and surface dirt cleaning machine for aluminum mold plate

A feeding device and feeding roller technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

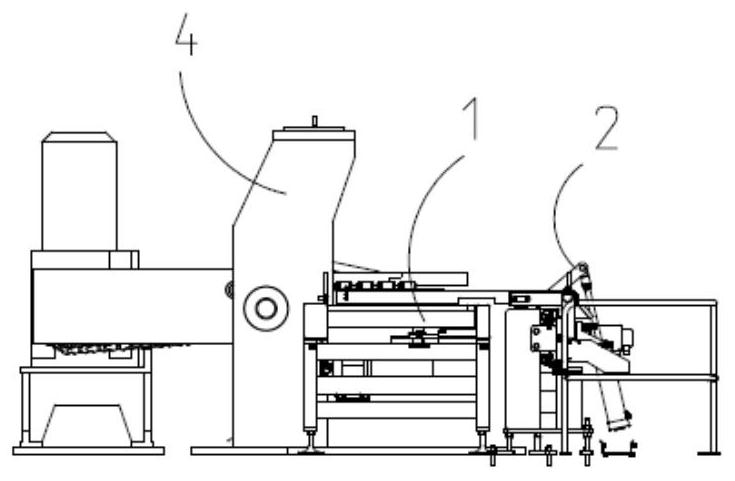

[0050] Please attach Figure 1-10, an alignment feeding device 200, comprising: a feeding frame 001, a feeding roller 002, a first chain drive unit, a roller power unit 005, and a deviation correction unit 006, and the feeding frame 001 includes a left material frame 0011 and a right material frame that are opposite and spaced apart 0012; the feeding roller 002 is located between the left material rack 0011 and the right material rack 0012; the feeding roller 002 is a plurality of intervals, and the two ends of each feeding roller 002 are respectively connected to the left material rack 0011 and the right material rack 0012 The rotation is connected; the first chain drive unit includes a first sprocket and a first chain, the number of the first sprocket is the same as that of the feed roller 002, and one end of each feed roller 002 in the same direction is respectively provided with a first sprocket, The first chain connects all the first sprockets in sequence to form a linkag...

Embodiment 2

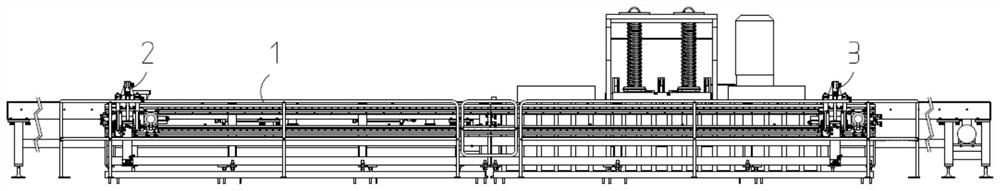

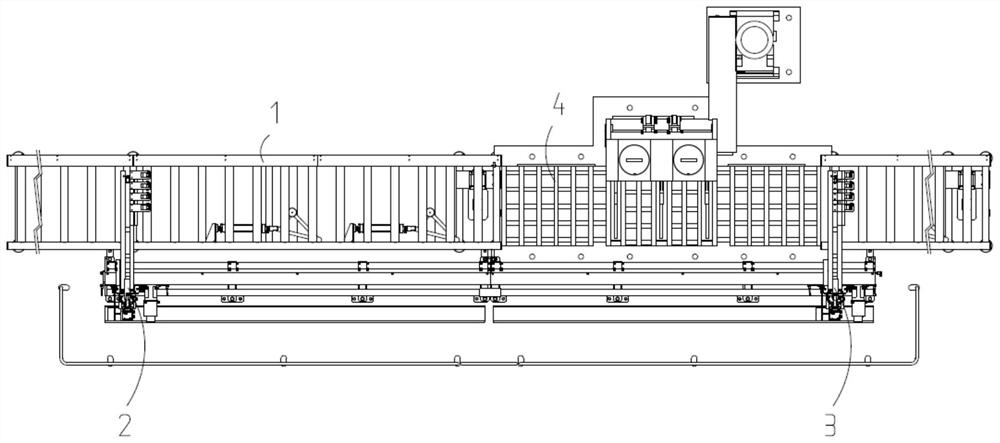

[0059] Please attach Figure 1-10 , this embodiment also provides a dirt cleaning machine on the surface of aluminum formwork, including the alignment feeding device 200 as in any section in Embodiment 1, the dirt cleaning machine on the surface of aluminum formwork also includes a frame 1, and The feeding unit 2 and the discharging unit 3, the wrestling table main body 4 arranged between the feeding unit 2 and the discharging unit 3, the feeding unit 2 and the discharging unit 3 are arranged at intervals, the feeding unit 2 and the discharging unit 3 The structure is the same; the frame 1 is arranged on one side of the length direction of the material rack and is far away from the left material rack 0011, and the wrestling table main body 4 is arranged on one side of the length direction of the material rack and is far away from the right material rack 0012; the feeding unit 2 It includes a rotating part 21 and a propulsion part 22; the rotating part 21 includes: a first fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com