Tube stock cutting device for automotive part manufacturing

A technology for auto parts and cutting devices, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve problems such as low work efficiency, pipe deformation, pipe incision deformation, etc., achieve small box, reduce occupation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

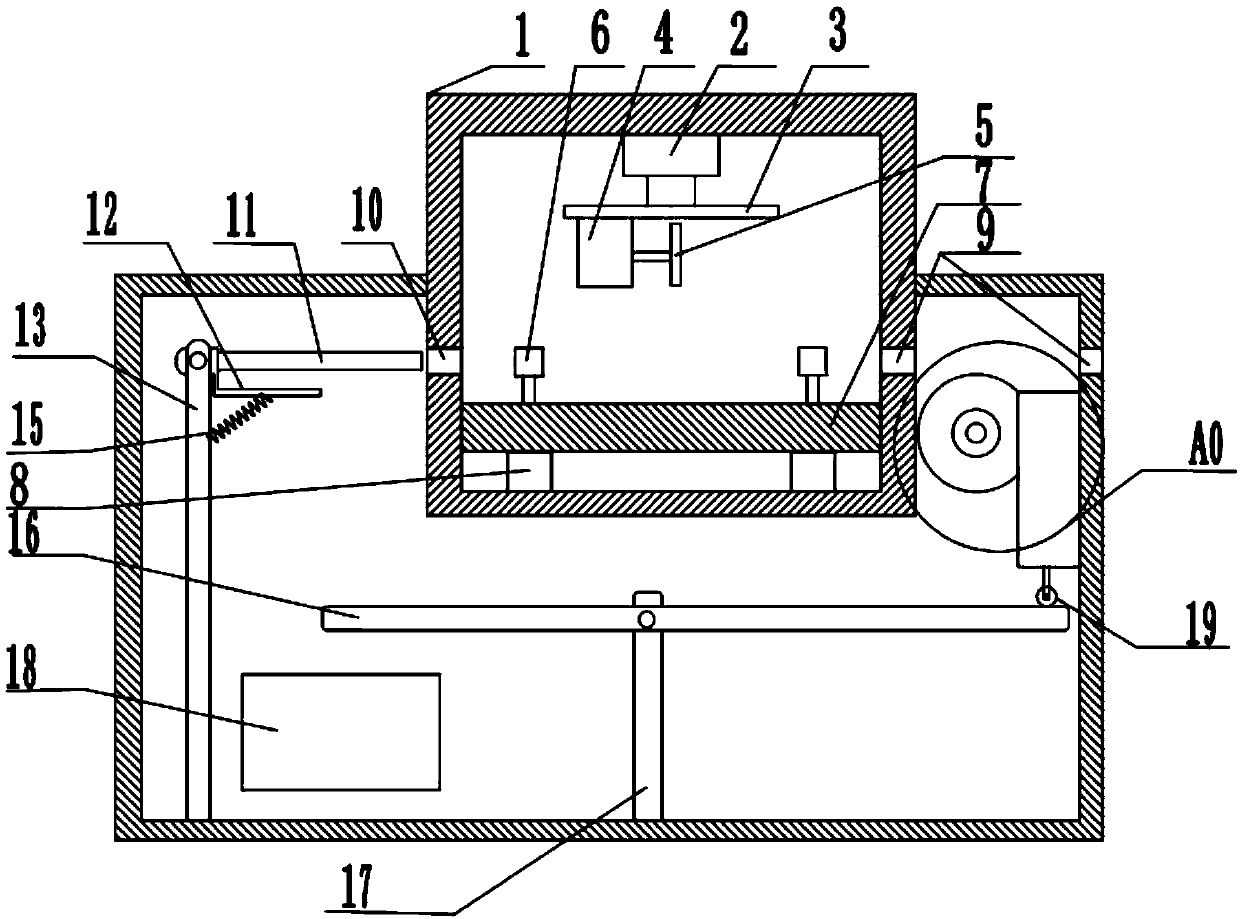

[0027] Basic as attached figure 1 Shown: a pipe cutting device for auto parts manufacturing, including a box 1, the box 1 is provided with a feed port 9, the box 1 includes a cutting chamber and a power transmission chamber arranged up and down, the cutting The side wall of the chamber is provided with a feed port 9 and a discharge port 10. The telescopic rod provided on the top of the cutting chamber is an electric telescopic rod 2, and the bottom of the electric telescopic rod 2 is fixedly provided with a fixed plate 3. The bottom of the plate 3 is fixedly provided with a motor 4, the rotating shaft of the motor 4 is connected with a cutting knife 5, and a cutting table is arranged below the cutting knife 5, and the cutting table includes a support plate 7 and four support blocks 8, and the four blocks The support blocks 8 are evenly and fixedly arranged on both sides of the bottom of the cutting chamber, the support plate 7 is arranged above the support block 8, and two set...

Embodiment 2

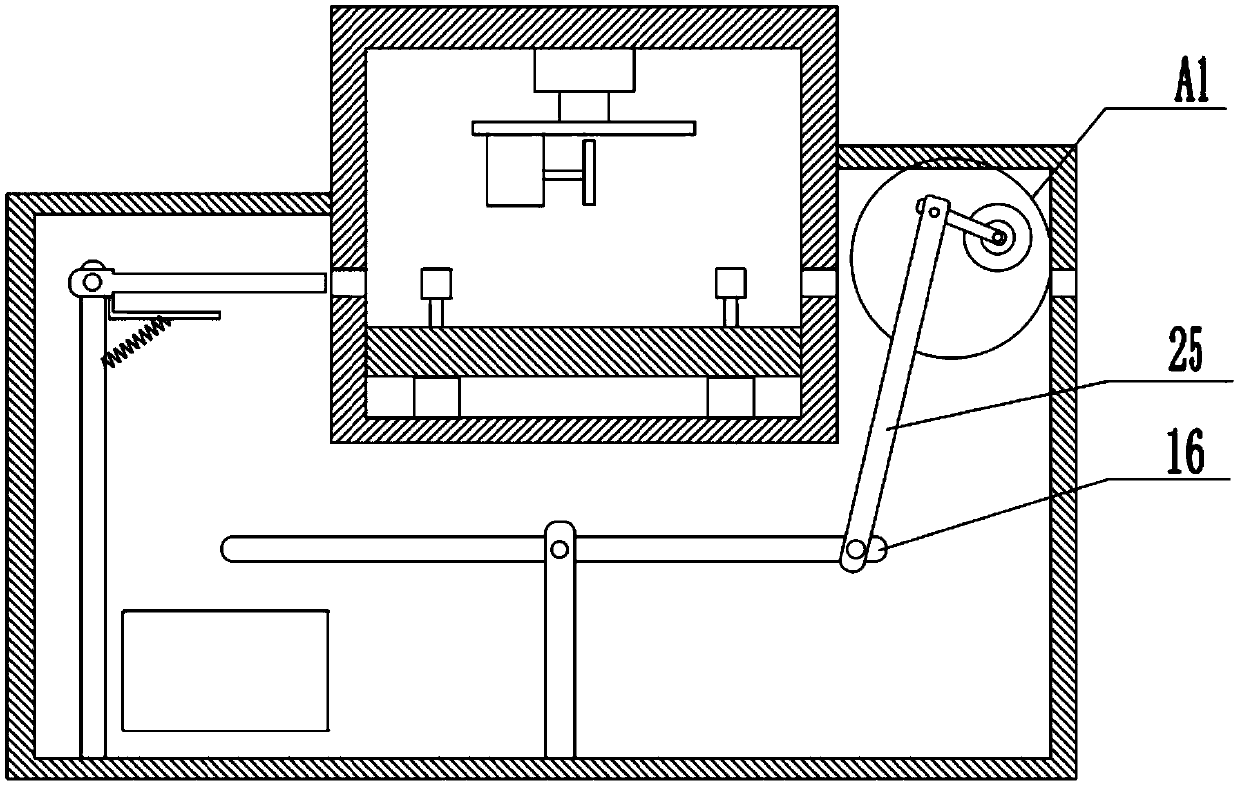

[0037] Basic as attached image 3 Shown:

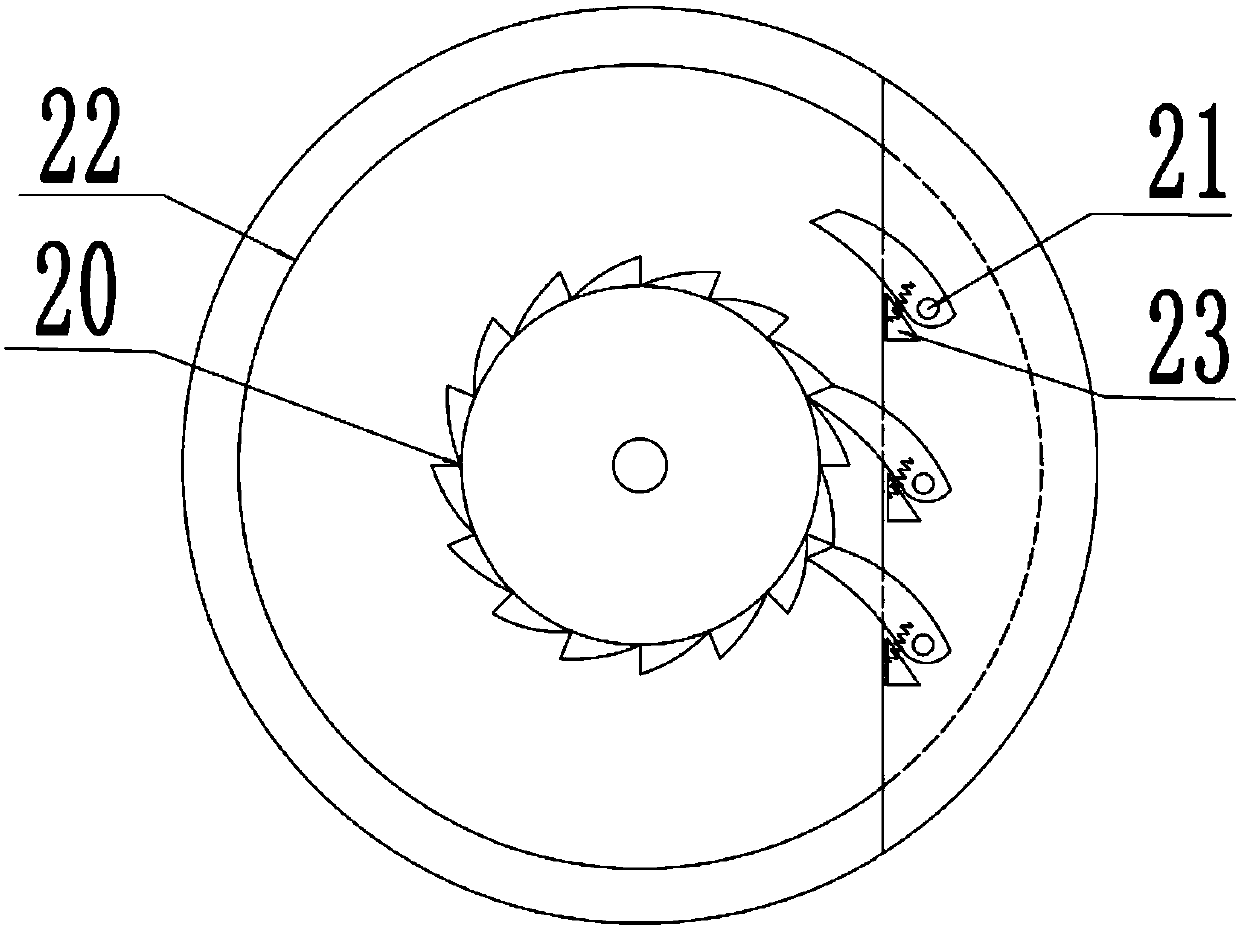

[0038] The difference between embodiment two and embodiment one is that the feed structure is different, such as Figure 4 As shown, the feed structure includes a connecting rod 24, a second swing rod 25, a ratchet 20, a transmission disc 22 and a pawl 21, and the ratchet 20 and the transmission disc 22 are fixedly connected to the rotating shaft and rotate with the outer wall of the power transmission chamber Connected, the transmission disc 22 is used to move the pipe to the cutting chamber, the circumferential surface of the transmission disc 22 is against the upper part of the pipe to be cut, and the two ends of the connecting rod 24 are respectively connected to the first swing rod 16 and the second One end of the two swing rods 25 is rotatably connected, and the other end of the second fork rod 25 is rotatably connected to the rotating shaft of the transmission disc 22, and the first fork rod 16, the connecting rod 24 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com