Full-automatic detecting system for power quality monitoring devices

A technology for power quality monitoring and equipment testing, which is applied in the direction of measuring electrical variables, measuring electricity, and measuring devices, and can solve problems such as inconsistency between the functions of power quality monitoring equipment and regulations, human errors, low work efficiency, and inconsistent sources of power quality standards , to facilitate retrieval and query, ensure data security, and shorten detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

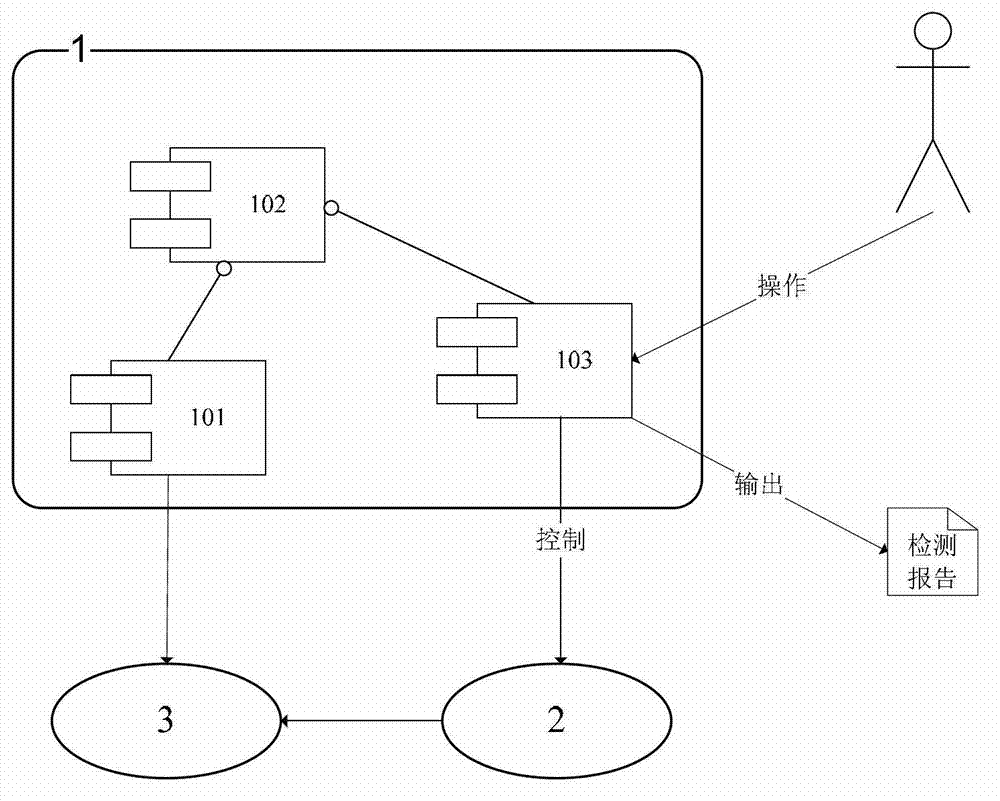

[0023] Combine below figure 1 The present invention will be further described with specific embodiments.

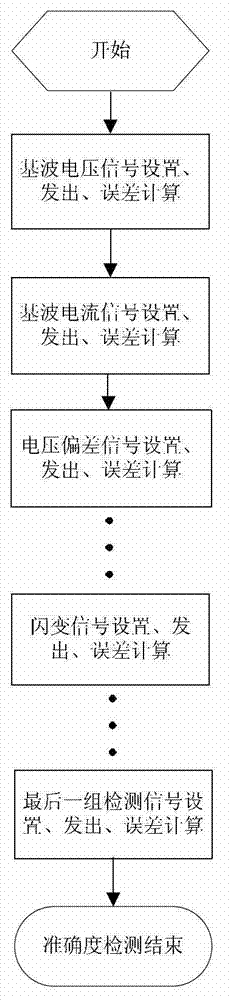

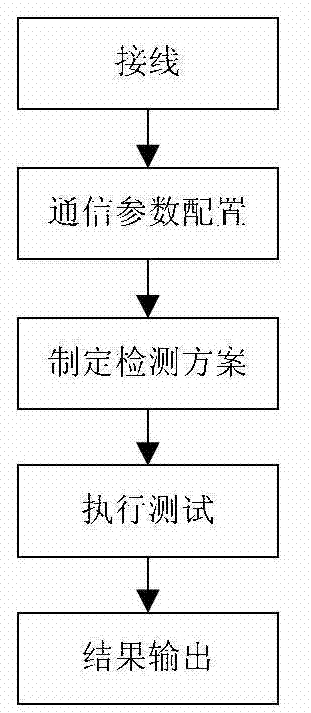

[0024] see figure 1 , the embodiment of the automatic power quality monitoring equipment detection system of the present invention is mainly composed of a host computer detection system 1, a standard source 2 and a monitored monitoring device 3. The host computer detection system 1 includes a data acquisition module 101, a data storage module 102 and Detection control module 103; the monitored monitoring equipment is connected to the standard source through the test signal line, the monitored monitoring equipment is connected to the upper computer through Ethernet, and the standard source is connected to the upper computer through the GPIB bus to form a closed-loop control system. The standard source adopts the Fluke6100A power source produced by Fluke Company. The system uses one Fluke6100A as the main engine and two Fluke6100A as auxiliary machines to simulate the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com