Full-automatic detection system and full-automatic detection method for sustainability of RFID (radio frequency identification device) logistic flat trays

A detection system, fully automatic technology, applied in the direction of optical testing flaws/defects, etc., to achieve broad application prospects, reduce storage tray space, and reduce the effect of the average detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Referring to the accompanying drawings, the present invention will be described in detail below.

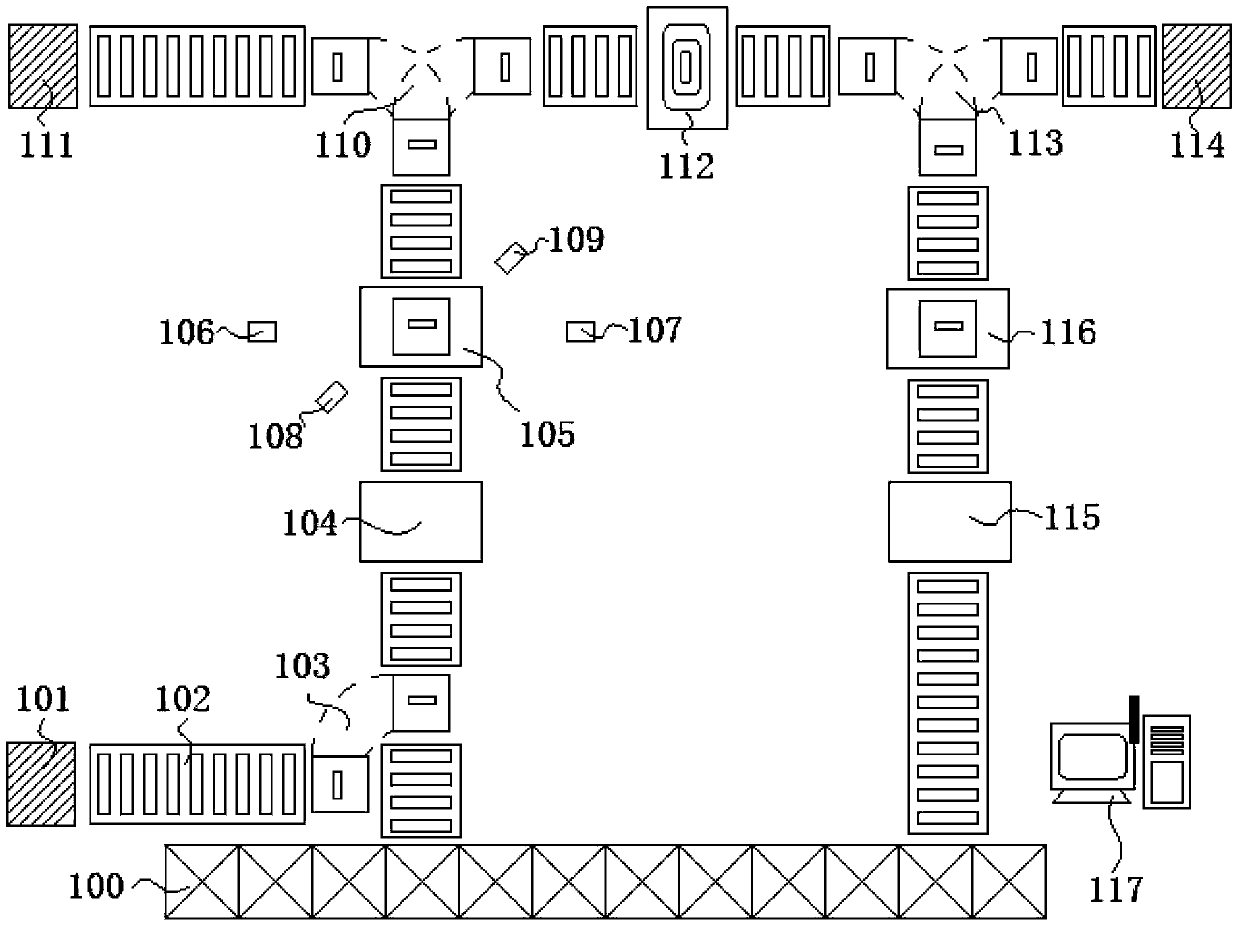

[0046] Such as figure 1As shown, the structure diagram of an RFID logistics flat pallet reusability detection system of the present invention, the system structure consists of a fully automatic elevated three-dimensional warehouse 100, a manual stacking position 101, a depalletizing machine 104, a first detection position 105, a first two-way Ninety-degree rotary conveyor belt 110, first elimination position 111, second detection position 112, second two-way ninety-degree rotary conveyor belt 113, second elimination position 114, stacking machine 115, expandable detection position 116, pallet detection management system 117 composition;

[0047] The fully automatic elevated three-dimensional warehouse 100 is used to store pallet stacks; a fully automatic stacker is used to perform pallet stacking / retrieval operations, and the stacker has a programmable function. According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com