Preparation method, grinding method and device for microsection sample

A technology of metallographic slicing and grinding device, which is applied in the preparation of test samples, etc., can solve the problems of inability to control the grinding position and depth, and achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

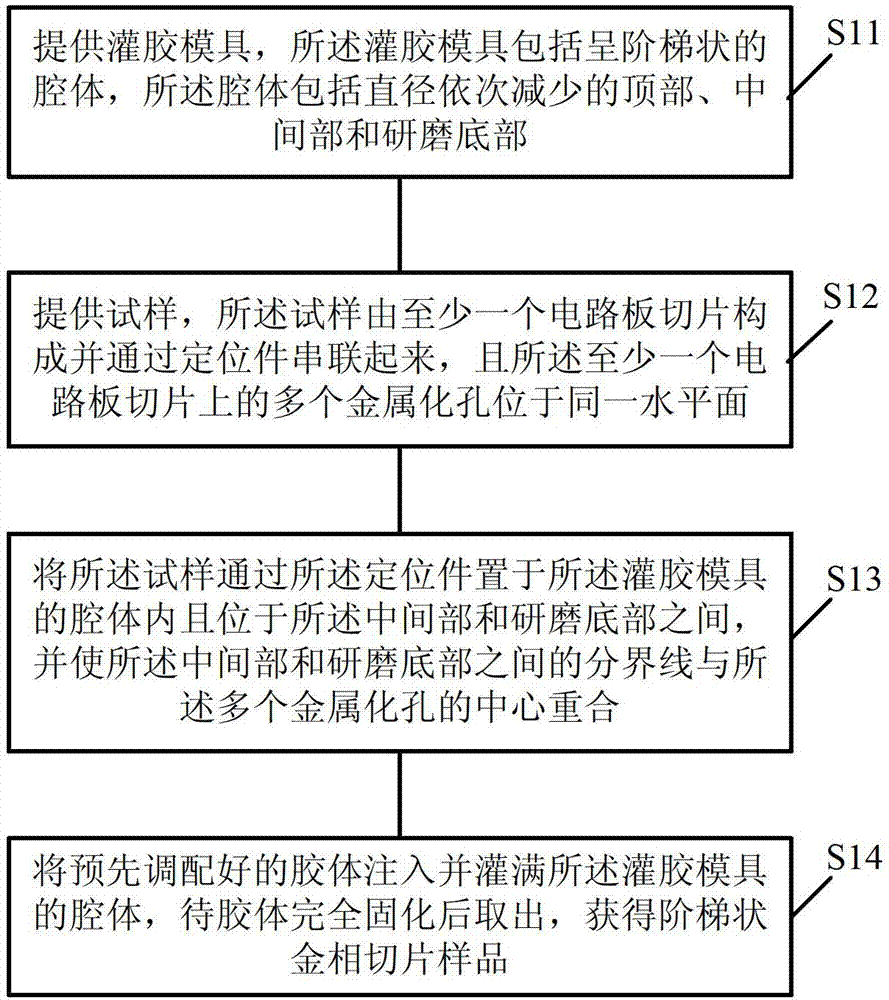

[0033] see figure 1 , the invention provides a kind of preparation method of metallographic section sample, comprises steps:

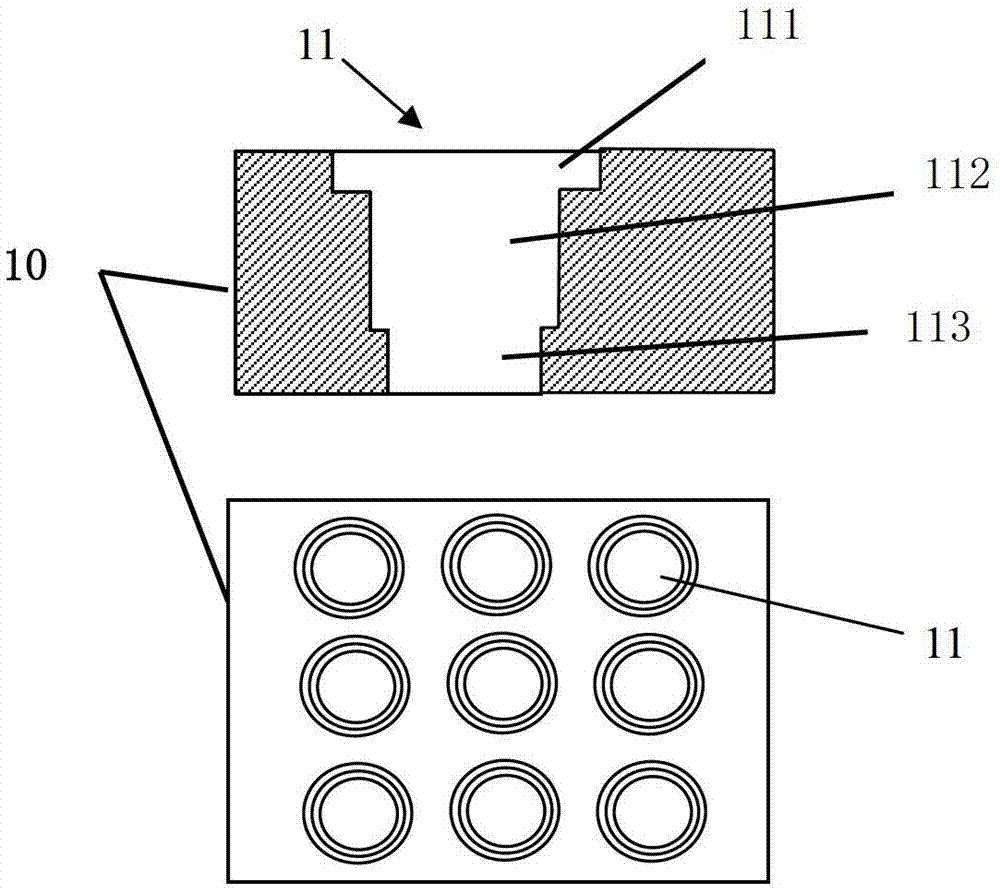

[0034] S11. Provide a glue filling mold, the glue filling mold includes a stepped cavity, and the cavity includes a top, a middle portion, and a bottom with successively decreasing diameters;

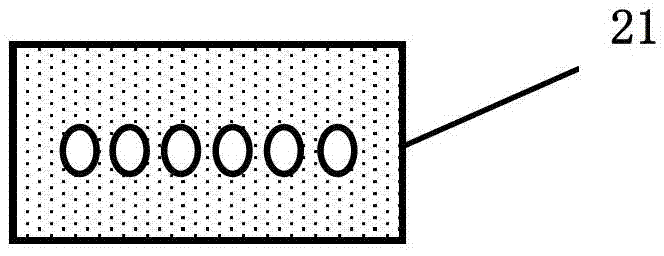

[0035] S12. Provide a sample to be tested, the sample to be tested is composed of at least one circuit board slice and connected in series through a positioning member, and the multiple metallized holes on the at least one circuit board slice are located on the same horizontal plane;

[0036] S13. Place the sample to be detected in the cavity of the glue filling mold through the positioning member and between the middle part and the bottom, and make the boundary line between the middle part and the bottom and the The centers of the multiple metallized holes are coincident;

[0037] S14. Inject the pre-prepared colloid into and fill the cavity of the glue filli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com