Four-axis numerical control polishing device special for graver

A technology of engraving knives and equipment, which is applied in the direction of grinding/polishing equipment, metal processing equipment, and other manufacturing equipment/tools, etc. It can solve the problems of low automation, poor tool accuracy and consistency, and cumbersome operation, so as to improve grinding efficiency. , save manpower, improve the effect of grinding accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

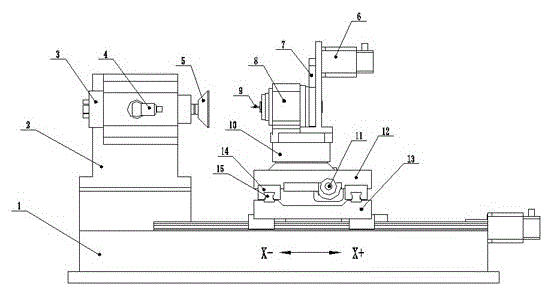

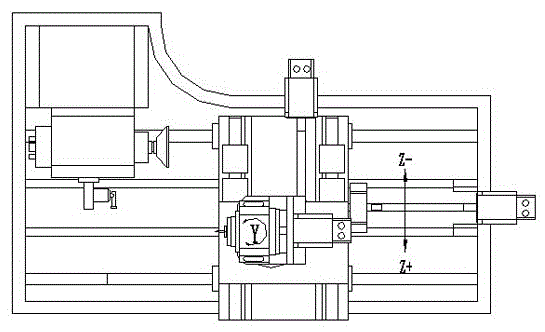

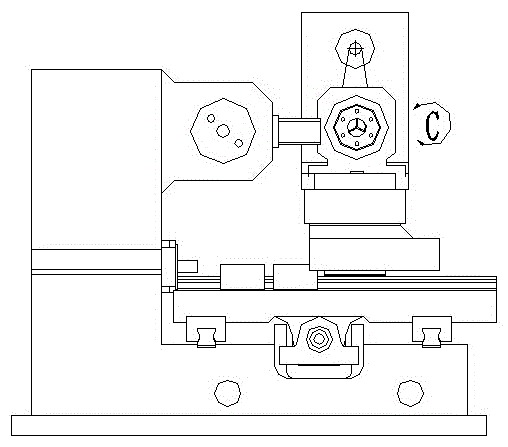

[0018] Such as figure 1 , 2 , 3, a dedicated four-axis CNC grinding equipment for engraving knives of the present invention includes a numerical control device and a base 1. The whole equipment is designed with X, Y, C, Z four axial moving mechanisms, so as to realize the multi-angle adjustment of the tool during the grinding process, and the numerical control device provides precise control for the whole equipment.

[0019] Specifically, a shaft seat 2 is provided above the left end of the base 1, and a grinding wheel 5 extending to the right side of the shaft seat 2 and capable of axial rotation is arranged transversely on the top of the shaft seat 2. The grinding wheel 5 is connected to the shaft seat 2 through an electric spindle 3, and Grinding wheel 5 is the conical shape that left side is narrow and right side is wide. The electric spindle 3 has the advantag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com