Hydraulic-spring mechanism reversing-valve valve spool and valve bush running-in device

A technology of hydraulic springs and reversing valves, which is applied in the direction of grinding devices, grinding machine tools, working carriers, etc., can solve problems such as difficult quality assurance, high labor intensity, and long grinding time, so as to ensure sealing, improve efficiency, and improve grinding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

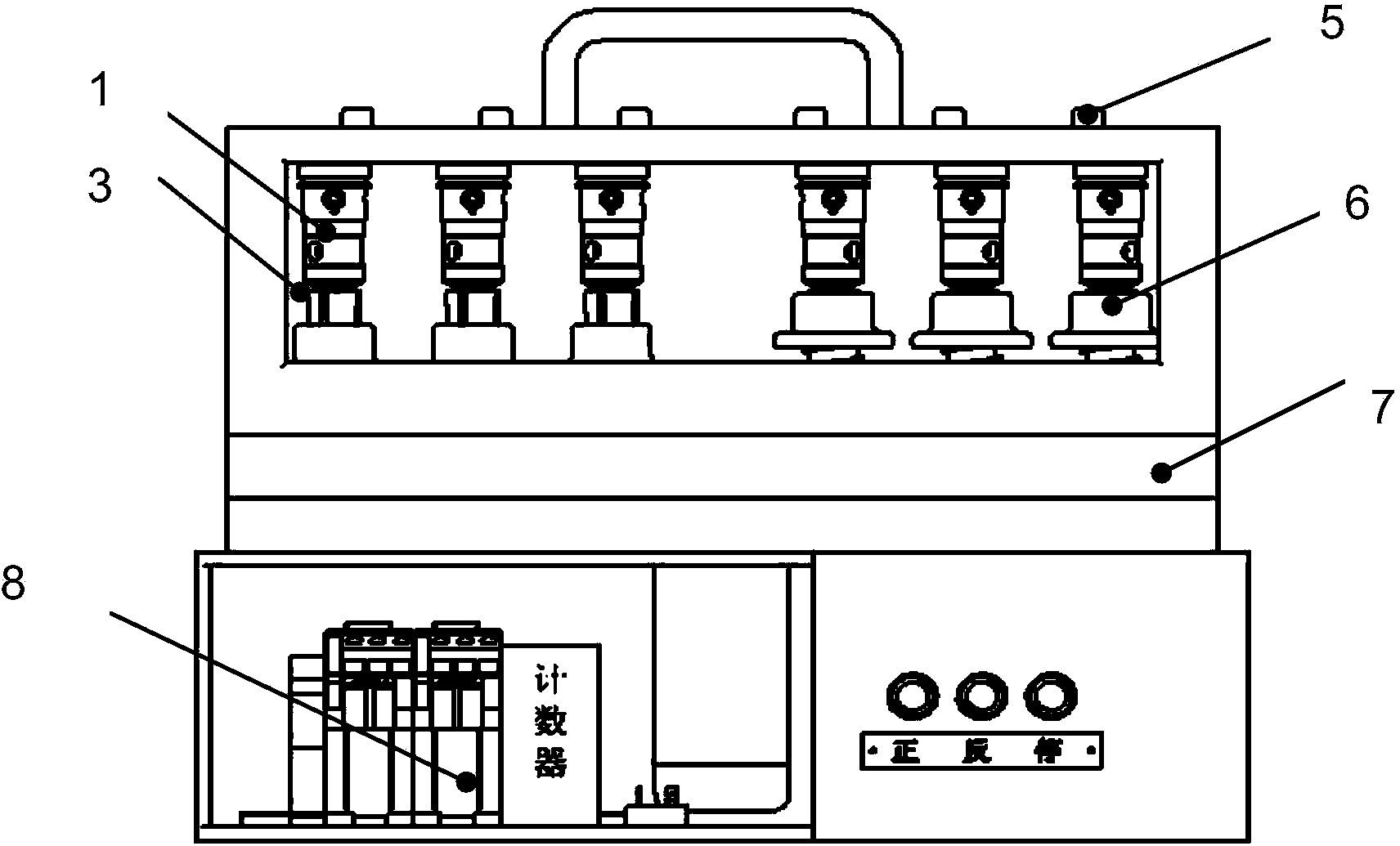

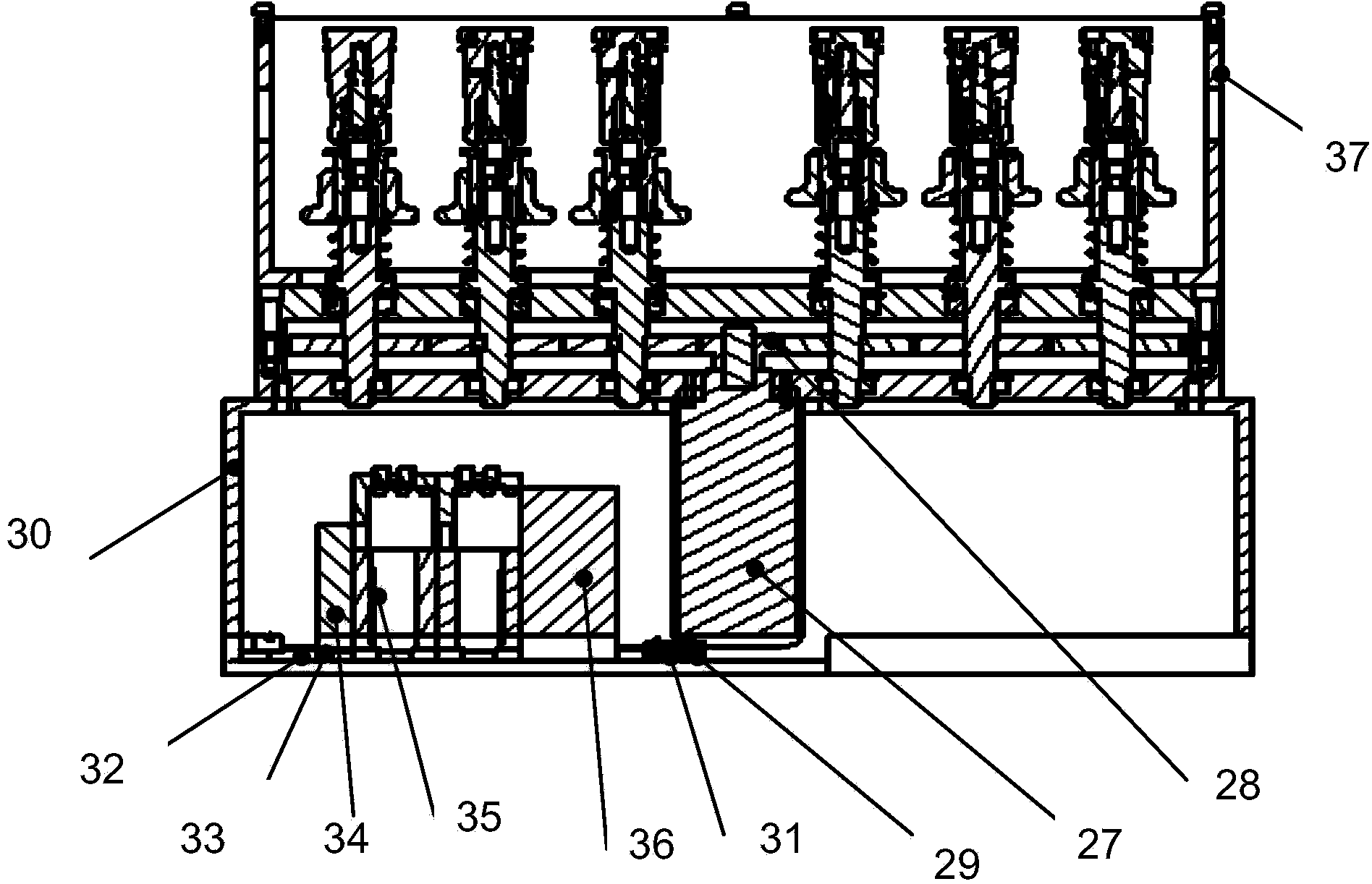

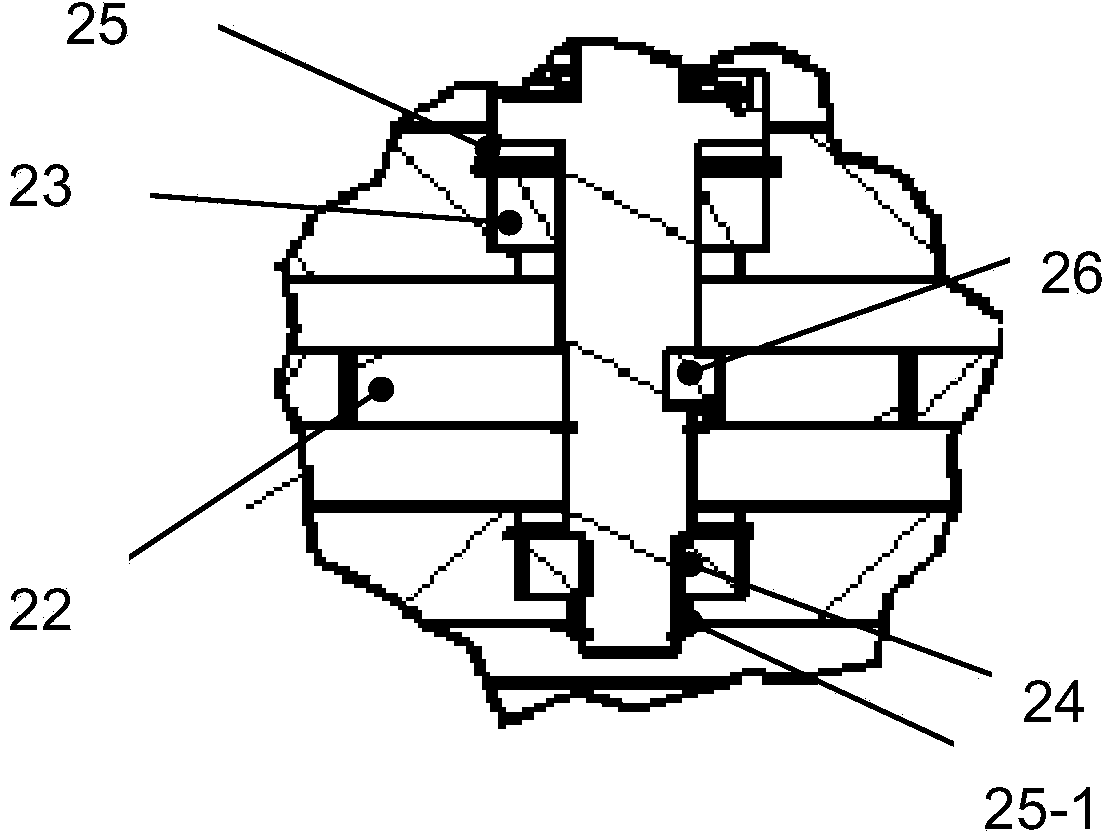

[0033] like figure 1 As shown, the hydraulic spring mechanism reversing valve spool valve sleeve matching research device includes a grinding box, the lower box 30 of the grinding box is provided with a control mechanism 8, and the upper box 37 of the grinding box is provided with a deceleration Mechanism 7, a grinding mechanism 3 is provided on the deceleration mechanism, and a guide mechanism 5 is provided on the top of the grinding mechanism 3 and on the cover of the upper box body 37; the grinding mechanism 3 includes at least a valve core 1 clamped by a clamping mechanism 6 , and the valve sleeve 2 sleeved on the valve core 1; the control mechanism drives the valve core 1 in the grinding mechanism 3 to rotate relative to the valve sleeve 2 through the motor 27 connected to the deceleration mechanism 7, so that the guide mechanism 5 in the grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com