Valve clack sphere grinding machine of double eccentric semi-ball valve

A hemispherical valve, double eccentric technology, applied in the direction of spherical grinder, grinder, grinding/polishing equipment, etc., can solve the problems of low production efficiency, irregular manual swing, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with embodiment example (accompanying drawing):

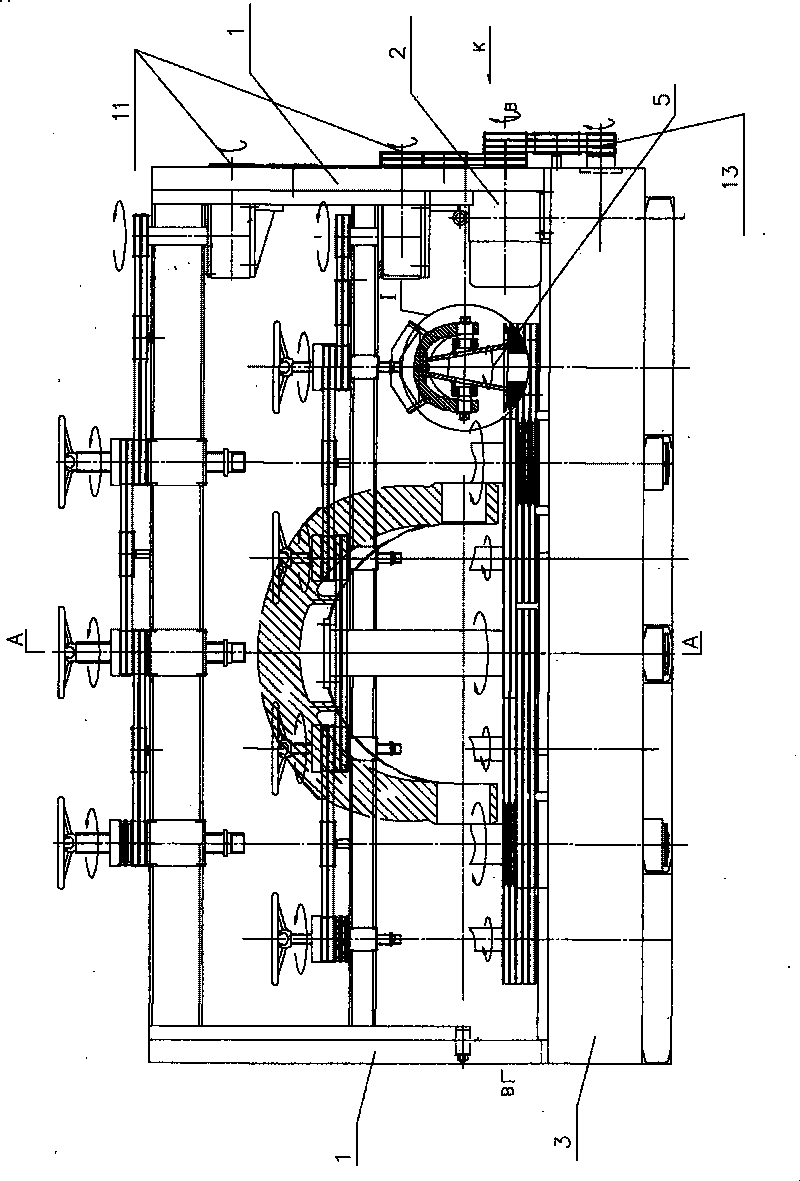

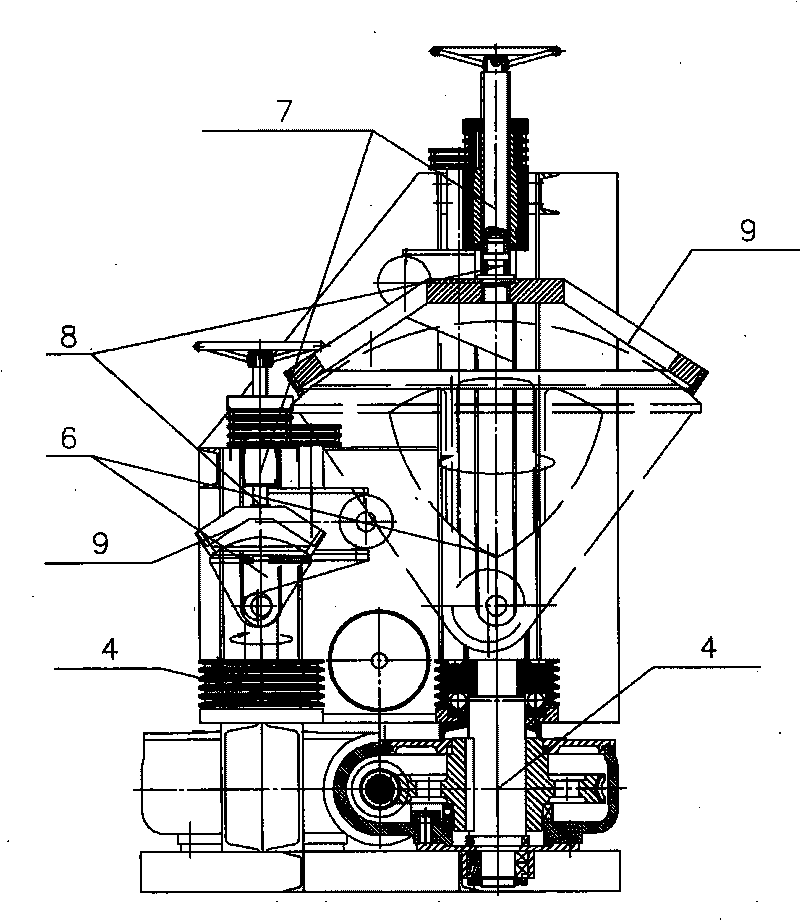

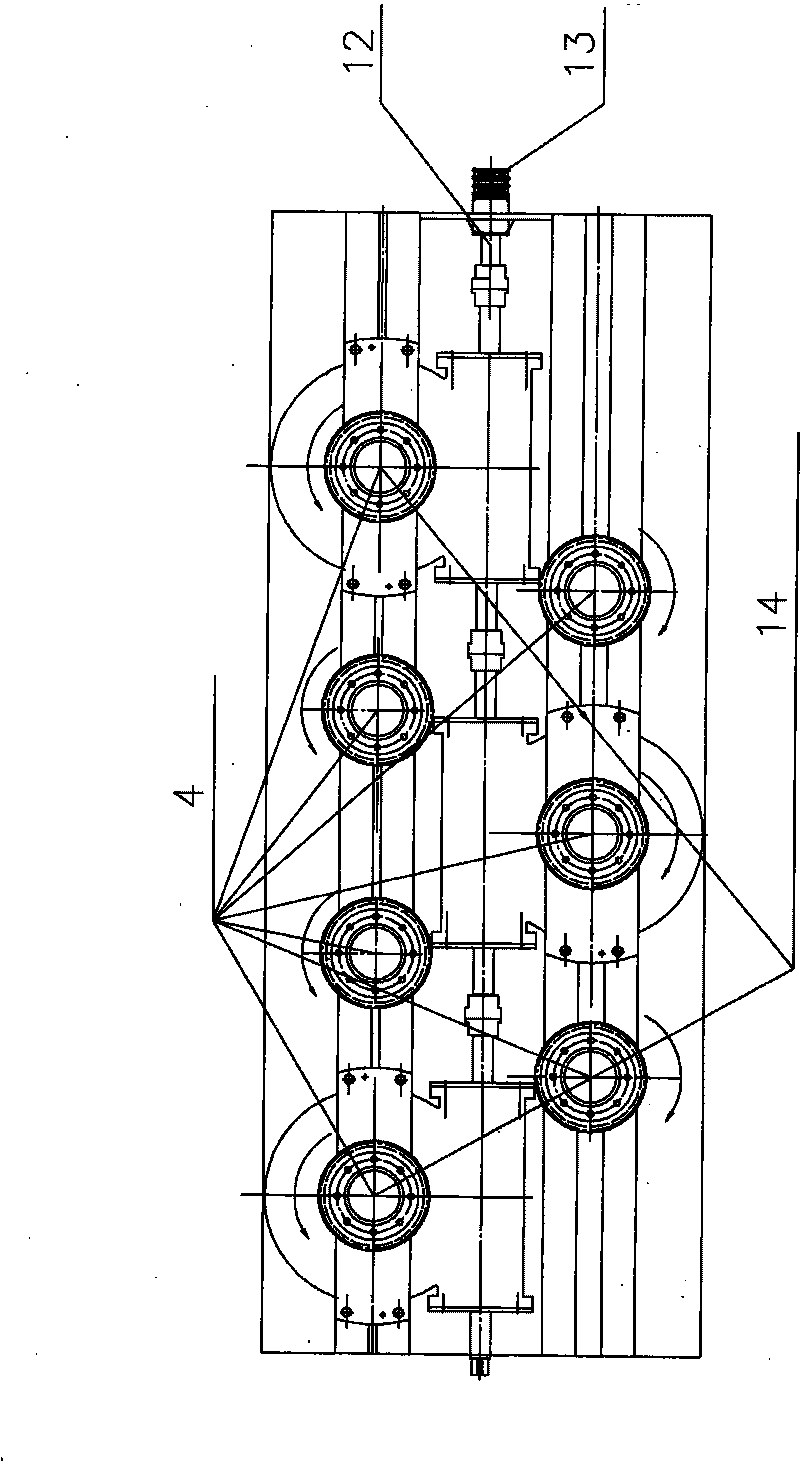

[0015] Such as figure 1 to combine figure 2 As shown, the hemispherical valve hemispherical grinder of the present invention is to set frame 1, motor 2 on support 3, carry workpiece rotating main shaft 4, tooling 5, and frame 1 is positioned at the top of support 3, on frame 1 is provided with an angle adjustment frame 6, and the adjustment angle of the angle adjustment frame 6 on the frame 1 is 10-25°, and for convenience of adjustment, an angle plate 16 (such as Figure 4 As shown), through the adjustment of the angle adjustment frame 6, the grinding body and the hemisphere are separated from the center by an angle, and the angle adjustment frame and the frame are fastened to form a reticulate shape under the condition of both rotating at the same time to achieve an ideal sealing surface . A rotating auxiliary shaft 7 is fixedly connected to the angle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com