Inner bore lapping machine for ceramic bushing used for optical fiber ceramic inserted core metal assembly

A technology of ceramic sleeve and ceramic ferrule, applied in grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of high labor intensity, large manual operation errors, hidden dangers, etc., to improve production efficiency and product quality, reduce Product processing cost and the effect of reducing quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

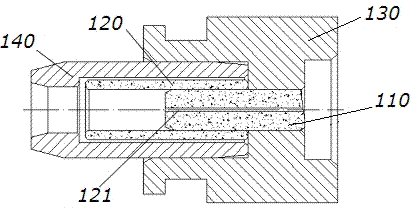

[0028] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

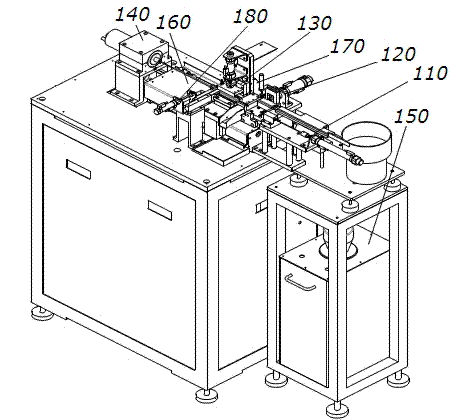

[0029] Such as figure 2 as shown, figure 2 It is a three-dimensional view of the inner hole grinder of the ceramic sleeve for the optical fiber ceramic ferrule metal assembly of the present invention. The inner hole automatic grinder includes a vibration sorting feeding unit 110, a dislocation pushing unit 120, a sleeve pressing unit 130, and a spindle rotating unit 140. Spindle cooling unit 150 , grinding cycle feeding unit 160 , abrasive automatic feeding unit 170 and automatic discharging unit 180 .

[0030] The purpose of setting the spindle cooling unit 150 is to automatically cool the high-speed rotating electric spindle and prolong the service time of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com