Flexible abrasive wheel and wheel blank of flexible abrasive wheel

A grinding wheel and flexible technology, which is applied in the field of flexible grinding wheels and flexible grinding wheel blanks, can solve problems such as easy to break, consume a lot of manpower and time, and consume a lot of energy, so as to reduce environmental pollution and energy consumption, and achieve good social value and The effect of improving economic value and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

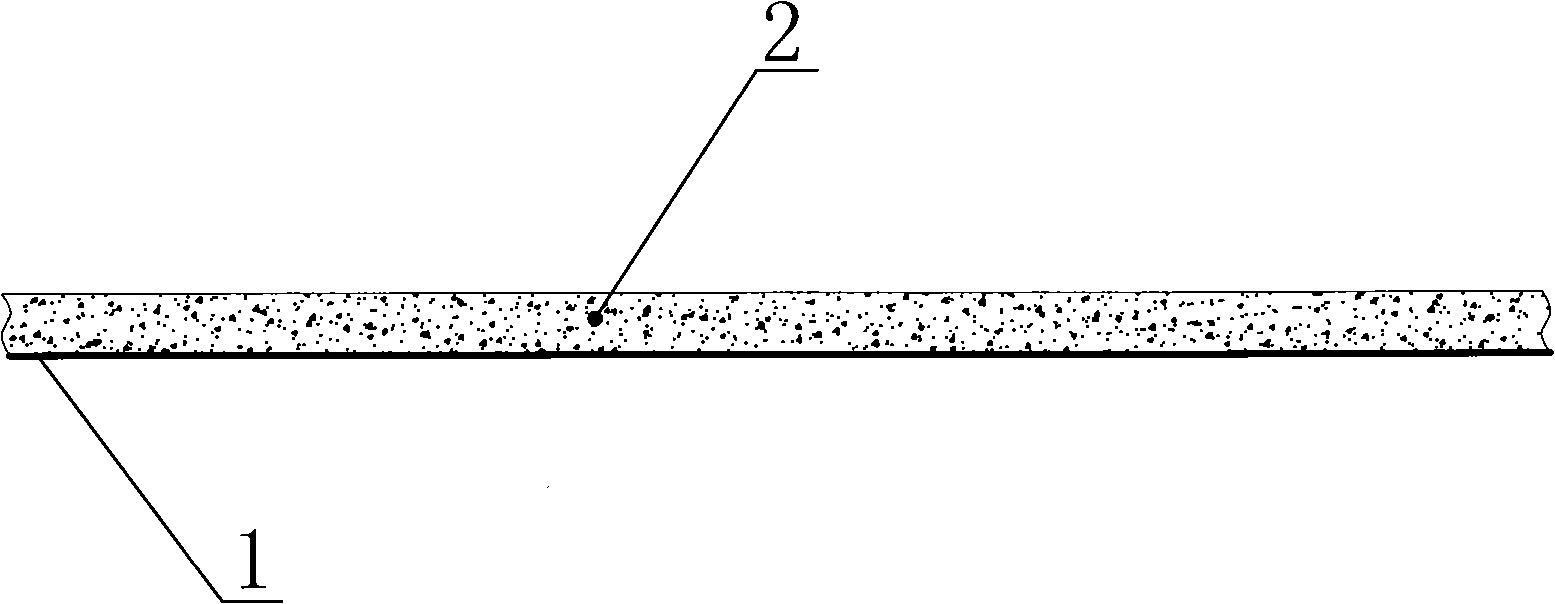

[0026] The structure of the emery cloth of the present invention is as figure 1 As shown, wherein 1 is a flexible cloth-like material, and 2 is abrasive grains; one surface of the flexible cloth-like material 1 is coated with an adhesive, and an electrostatic sand-planting process is adopted on this surface to make sand-planting cloth, and the abrasive grains 2 The root and the flexible cloth-like material 1 are bonded together by an adhesive, and the top of the abrasive grit 2 is exposed.

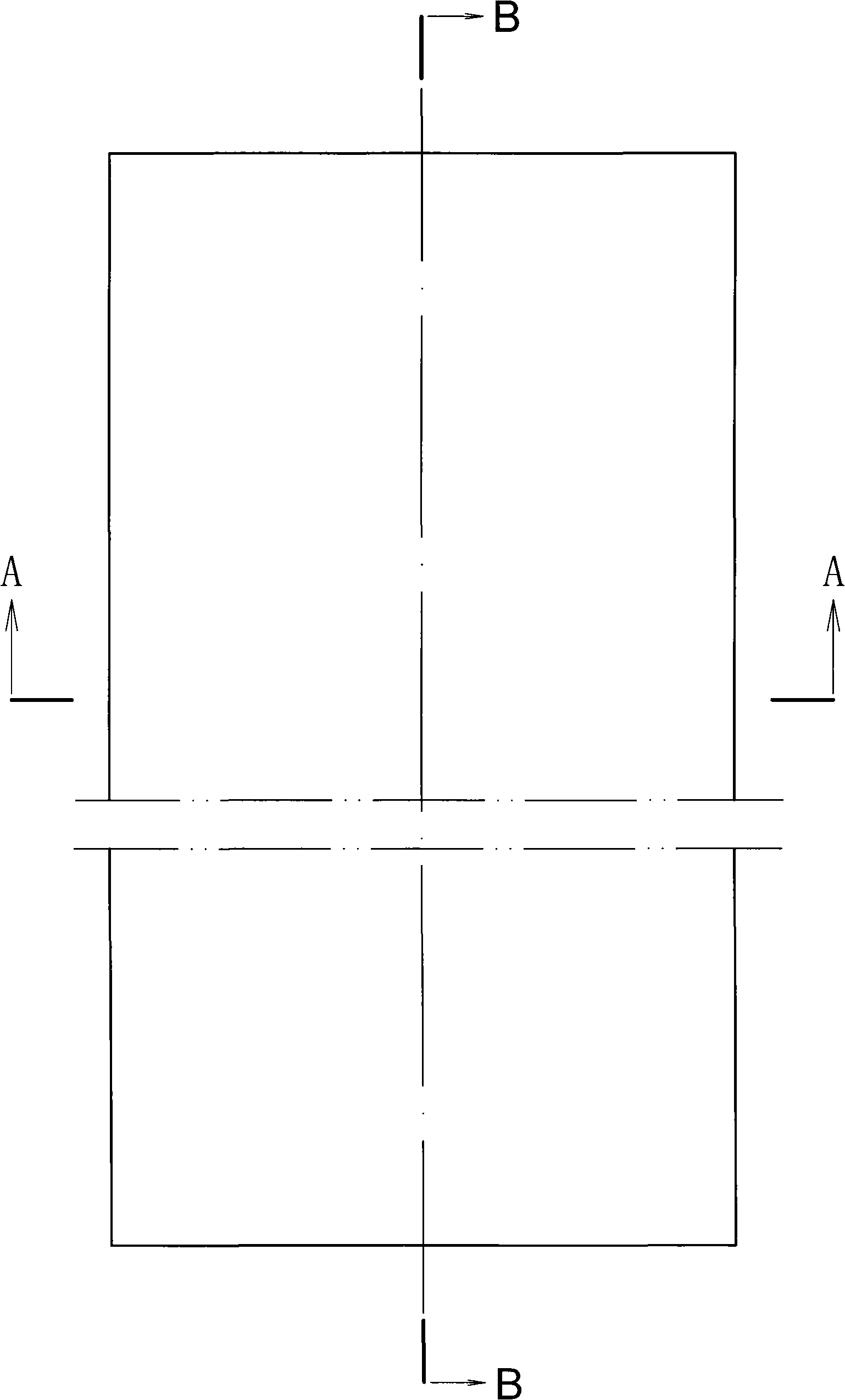

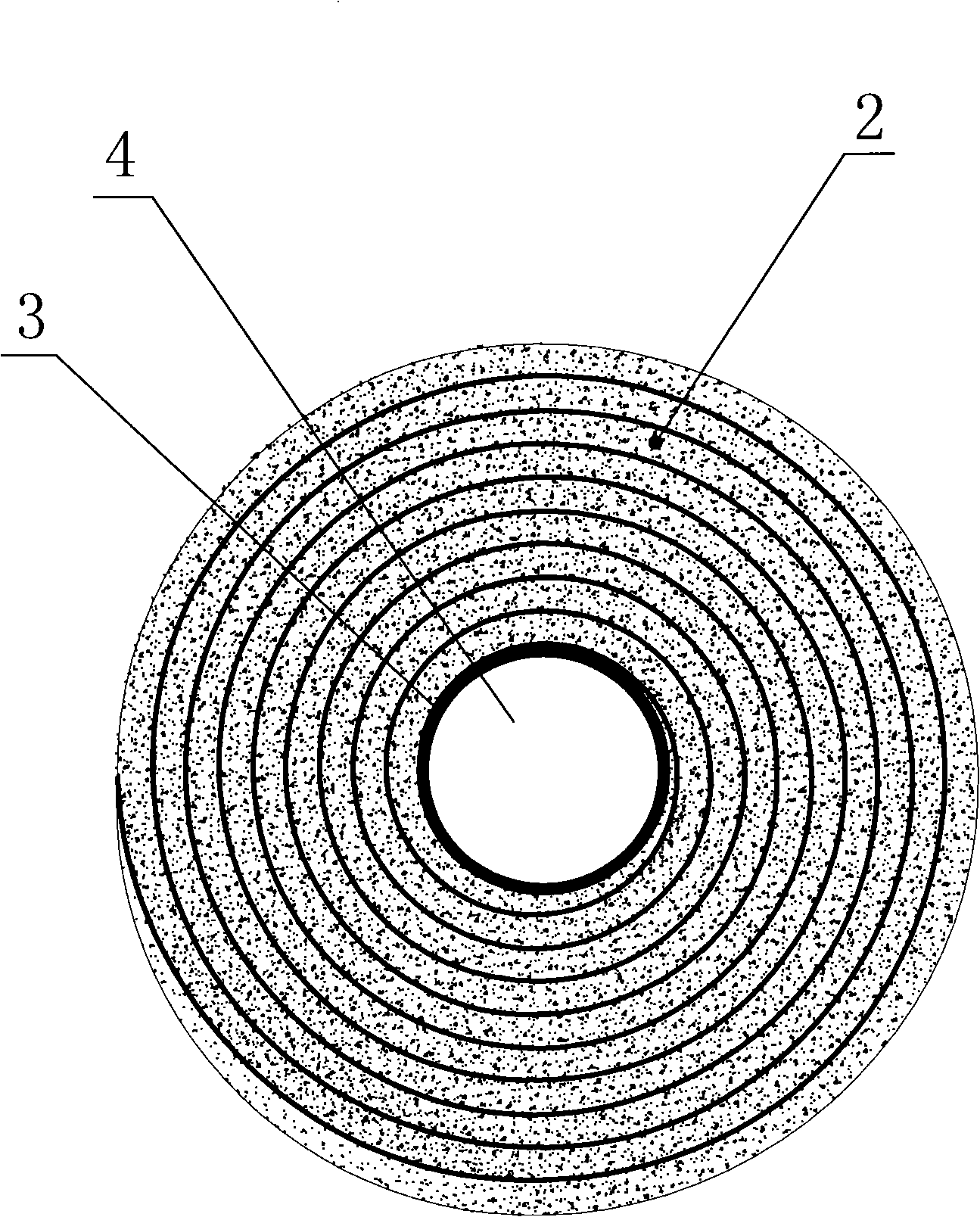

[0027] The structure of the flexible grinding wheel blank of the present invention is as Figure 2~4 As shown, the flexible grinding wheel blank uses wide-width emery cloth as the raw material. When making it, the emery cloth is wound around the center hole 4 with the sand-containing surface facing the outside, and the adjacent emery cloth rolls are bonded together by an adhesive. into a flexible grinding wheel blank, and a mounting sleeve 3 is bonded and fixed in the central hole 4; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com