Numerical control automatic tooth profile strength forming grinder

A fully automatic, tooth-shaped technology, applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of unsuitable grinding wheel dressers, poor rigidity of the supporting structure of the dressing wheel, and complex structure, etc., to achieve Improved sawing efficiency, improved processing efficiency, and high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

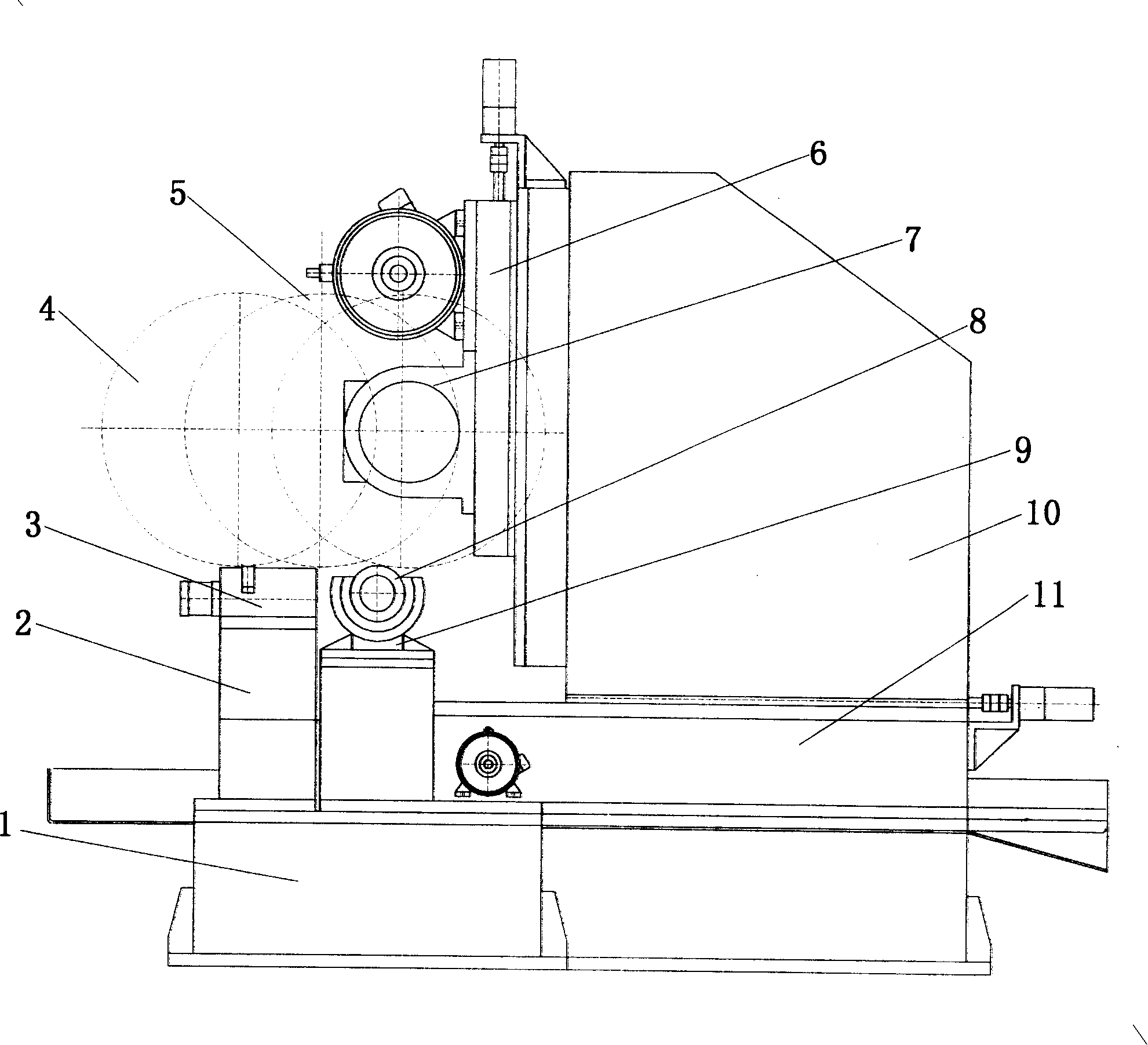

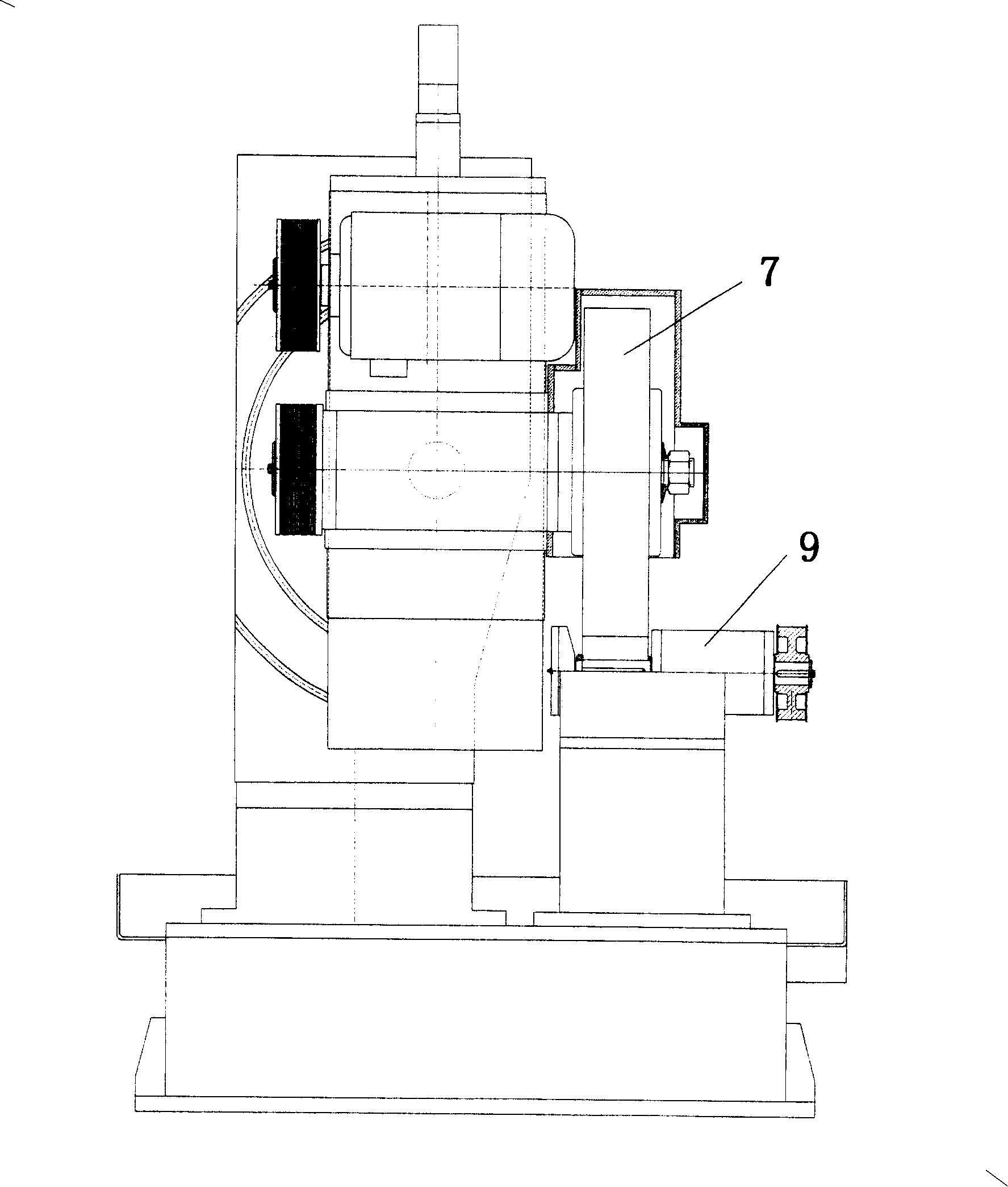

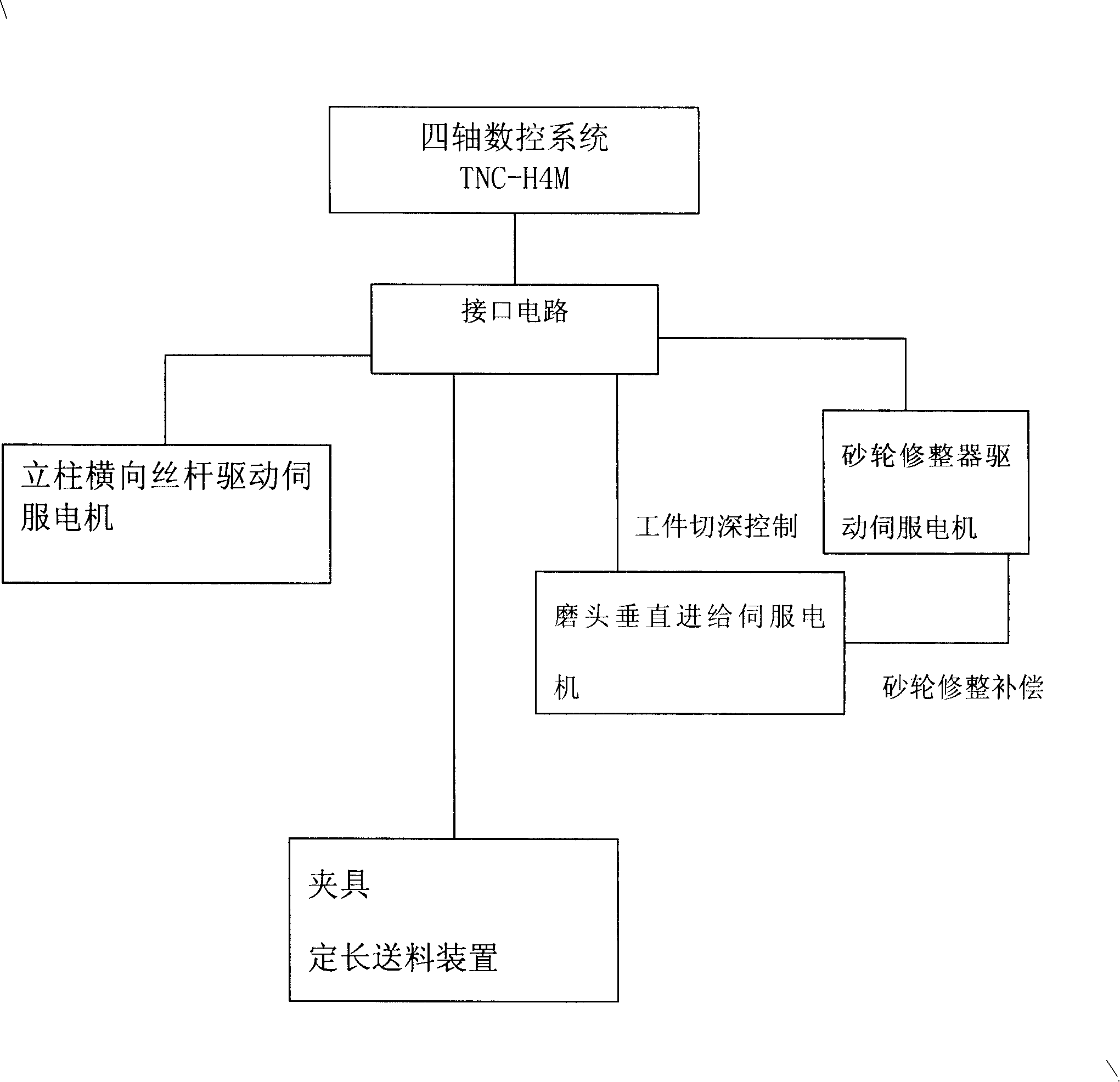

[0020] The powerful forming grinder of the present invention is such as figure 1 , figure 2 As shown, the column 10 is installed on the guide rail of the bed 1, and the column 10 can move back and forth along the rail under the drive of the transverse feed mechanism 11. The grinding wheel 7 is installed on the column 10 through the vertical feed mechanism 6. The vertical feed mechanism 6 The grinding wheel 7 can be moved up and down along the column 10.

[0021] The workbench 2 and the dresser 9 are fixedly installed on the bed 1, the dresser 9 is located behind the workbench 2, there is a dressing wheel 8 in the dresser 9, and the dressing wheel 8 is located under the grinding wheel 7. The workbench 2 is provided with a clamp 3 for clamping the workpiece to be ground. When the column 10 is driven forward by the transverse feed mechanism 11, the grinding wheel 7 can grind the workpiece. At this time, the grinding wheel 7 In the working position 4, when the grinding wheel 7 is wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com