Resin binder grinding tool and manufacturing method thereof

A binder and resin technology, applied in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of reducing the production cost of ceramic tiles, fast diamond wear, and large heat generation, to improve chip removal performance, improve cooling effect, The effect of reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The first embodiment of the resin bond abrasive tool

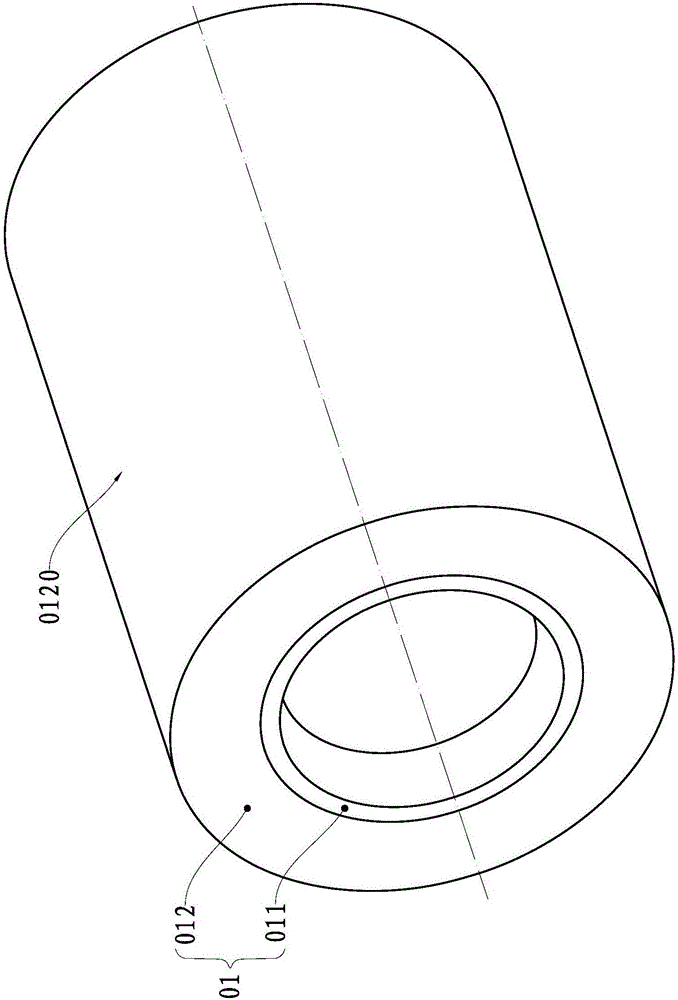

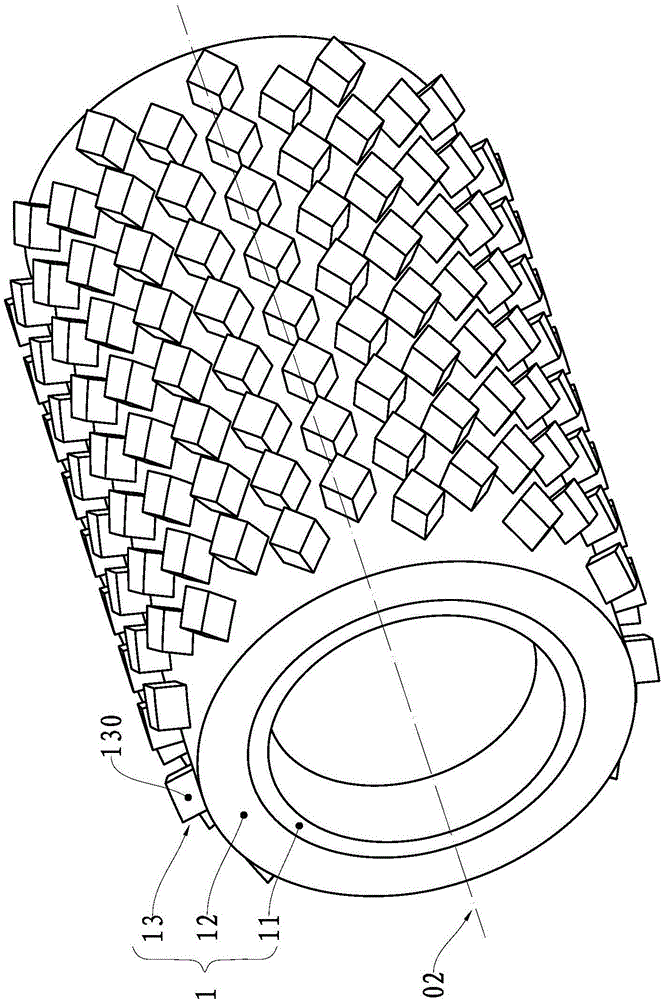

[0040] In this embodiment, the resin-bonded abrasive is a grinding wheel for polishing ceramic tile blanks.

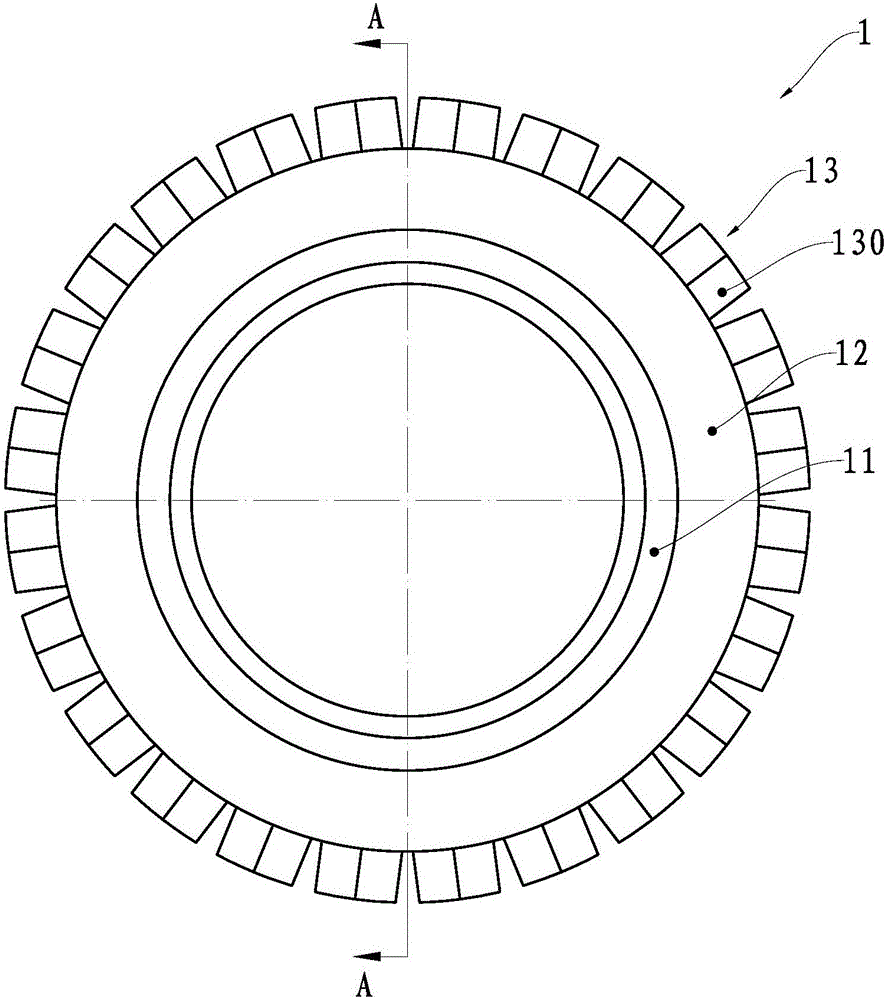

[0041] see Figure 2 to Figure 4 The grinding wheel 1 for polishing ceramic tile blanks is composed of a mandrel 11, a cylindrical elastic layer 12 and a grinding layer 13. The grinding layer 13 is arranged in a plurality of rows along the direction parallel to the rotation axis 02 of the grinding wheel 1 for polishing ceramic tile blanks. The rotation axis 02 is the axis around which the grinding wheel 1 rotates during the work process, and the grinding block row is composed of more than two grinding wheels fixed on the outer peripheral surface of the cylindrical elastic layer 12. The cutting block 130 is composed, that is, the cylindrical elastic layer 12 is fixed between the mandrel 11 and the grinding layer 13 .

[0042] see Figure 5 , the grinding block 130 is a prism structure, and its cross-sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com