Vitrified metal bond abrasive tool and manufacturing method thereof

A metal bond, ceramic metal technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of abrasive tool life, sharpness, reduced grinding performance, unsatisfactory cooling effect, and increased graphite usage. , to achieve the effect of improving cooling effect, reducing leakage rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

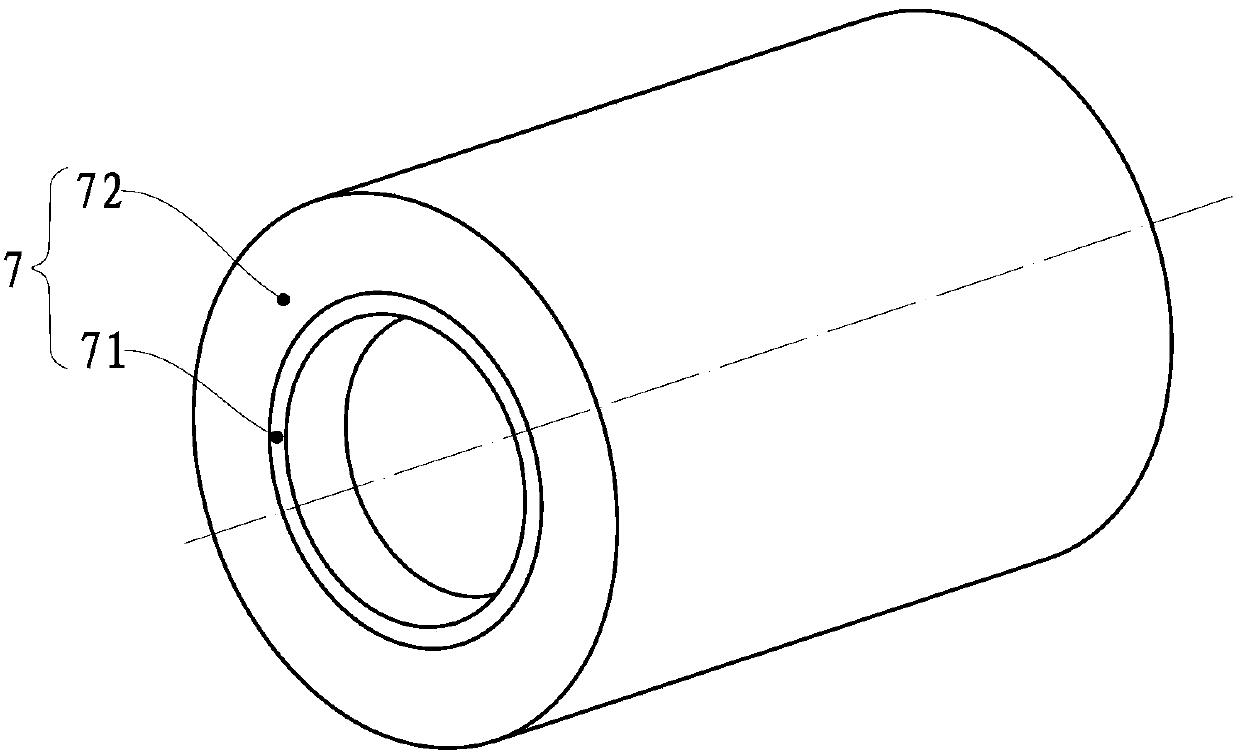

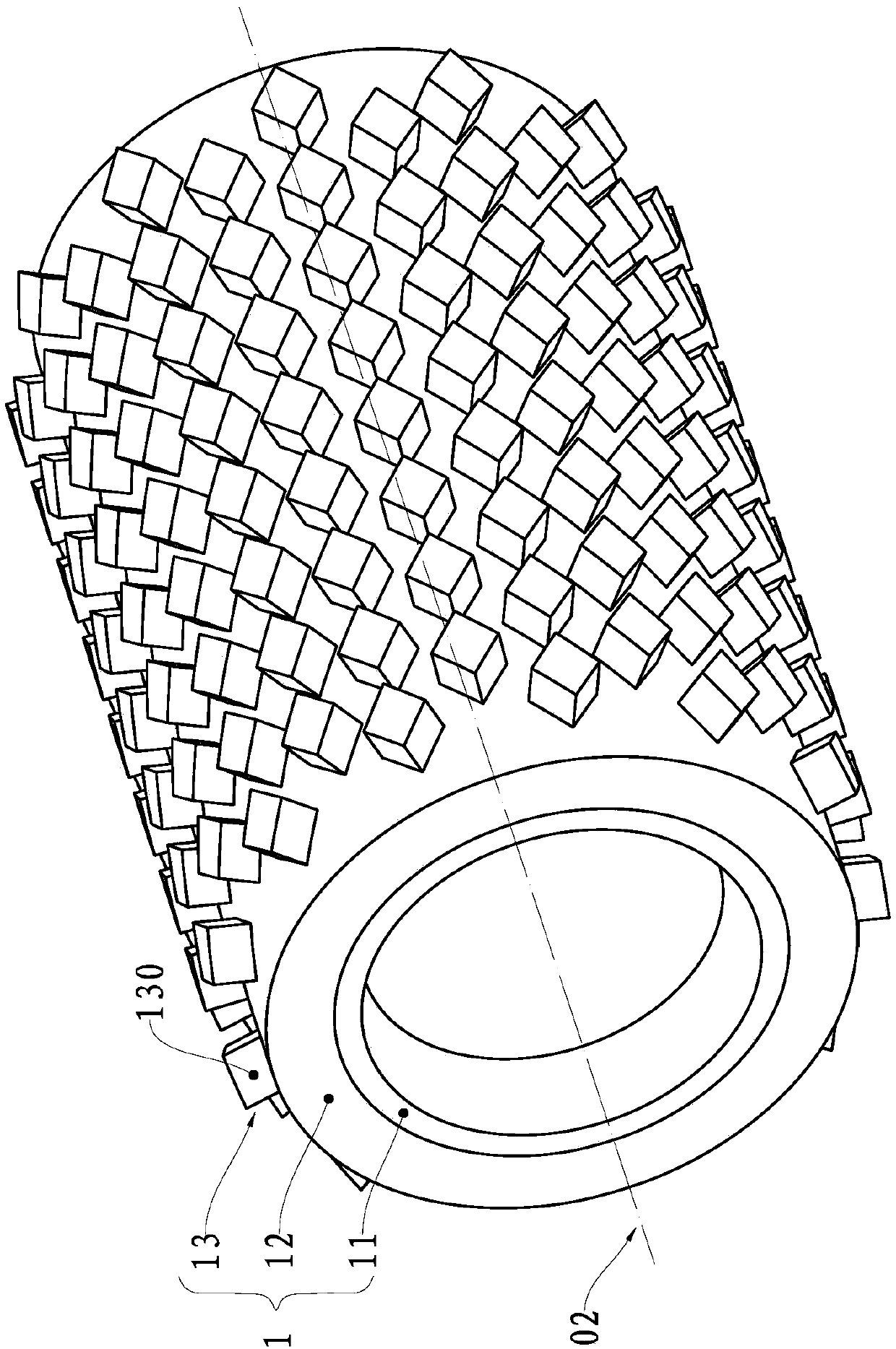

[0037] see figure 1 , The vitrified metal bond abrasive tool 7 is composed of a mandrel 71 and a grinding layer 72 . The grinding layer 72 is a cylindrical structure set outside the mandrel 71 and fixedly connected thereto. The mandrel 71 is made of steel.

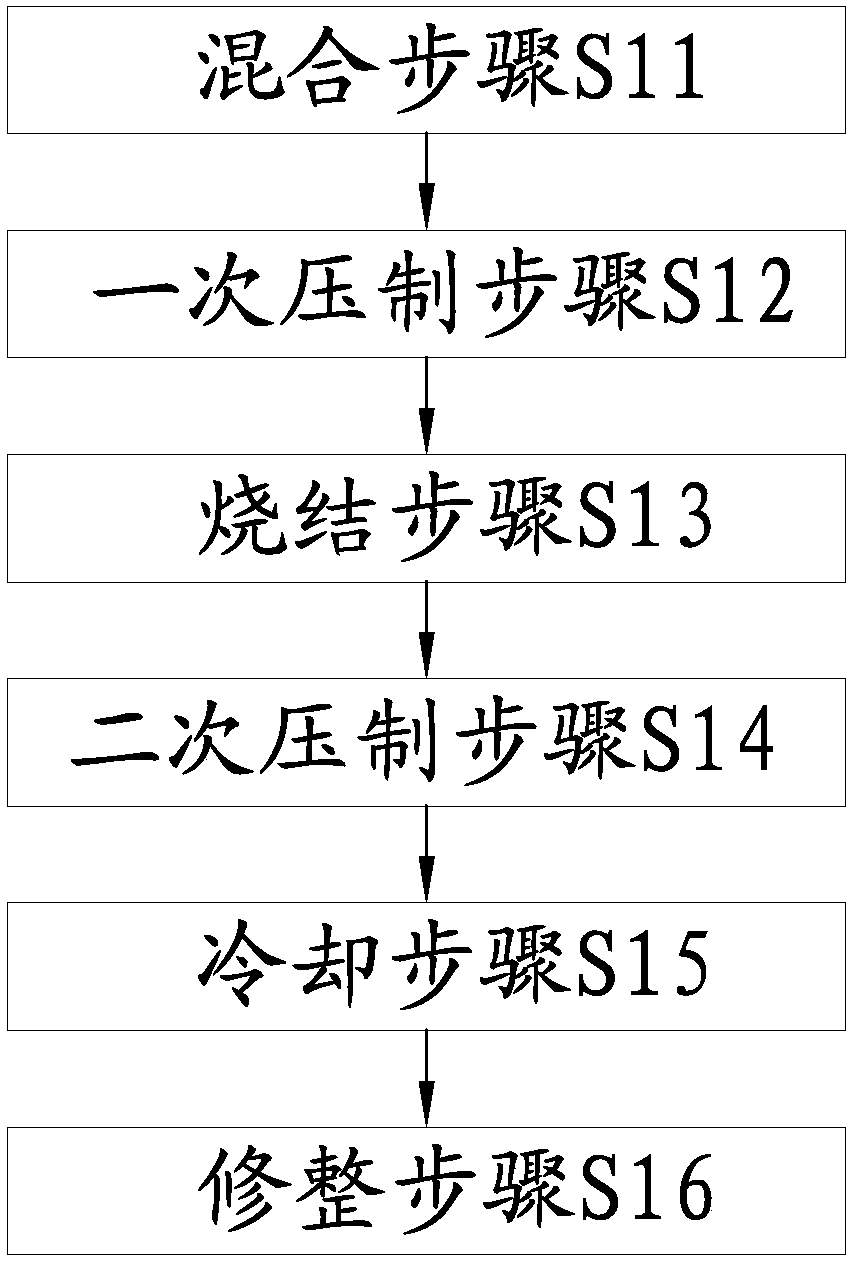

[0038] see figure 2 , The method for manufacturing the vitrified metal bonded abrasive tool 7 is composed of a mixing step S11, a primary pressing step S12, a sintering step S13, a secondary pressing step S14, a cooling step S15 and a dressing step S16. In this embodiment, the primary pressing step is a cold pressing step.

[0039] Mixing step S11: Weigh the electrolytic iron powder, cobalt powder, nickel powder, tin powder and ultrafine copper powder according to the specifications and parts by weight in Table 1 and put them in a mixer and mix them for 3-4 hours until they are evenly mixed; Weigh diamond, Ti 3 AlC 2 and liquid paraffin into the mixer, and mix for 3-4 hours to mix well. Iron powder, cobalt powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com