Tile grinding cooling method and device

A cooling method and grinding technology, applied in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as rough brick surface, large grinding amount, and scratches , to avoid burn marks and scratches, reduce temperature and save water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

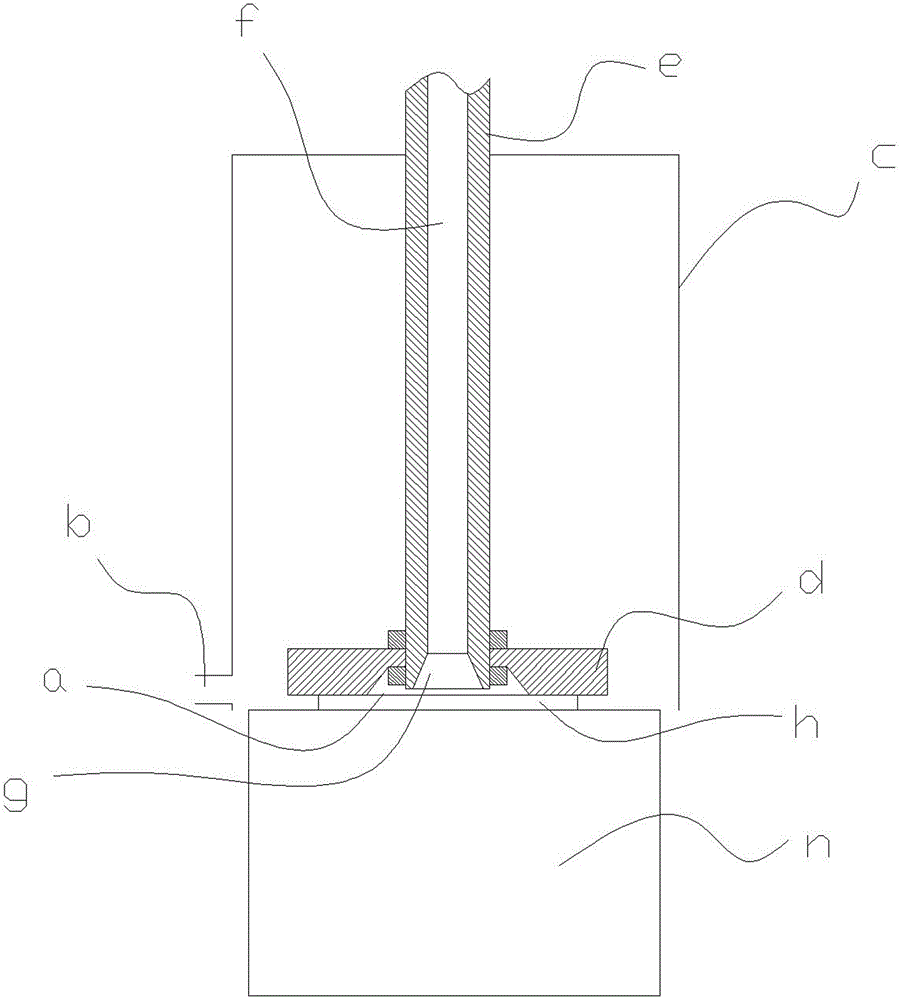

[0014] Embodiment 1 of the cooling device for ceramic chip grinding: as figure 1 As shown, the present invention includes a dust cover c with an air outlet b on the side of the grinding place a of the tile h facing the surface polishing, an air guide hole f arranged on the axis of the transmission shaft e for driving the grinding wheel d, and the transmission The shaft e penetrates into the dustproof cover c, and the horn-shaped air outlet g on the end face of the drive shaft f faces the polished surface of the ceramic tile h. The tile h is driven forward by the belt conveyor n.

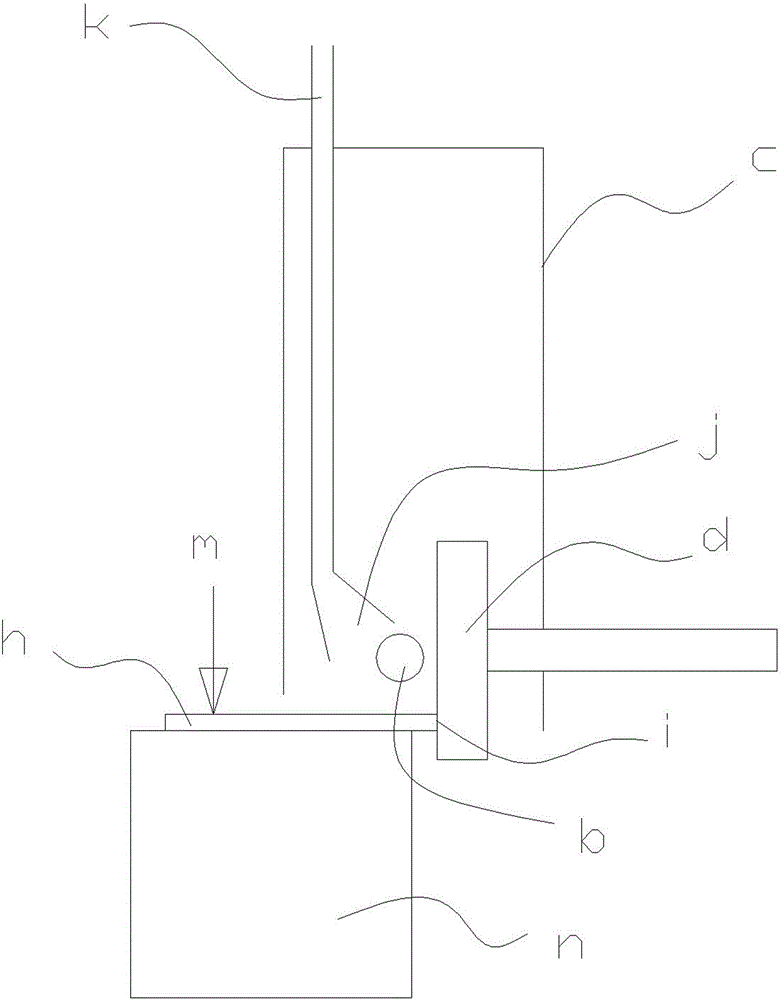

[0015] The second embodiment of the cooling device for porcelain chip grinding: as figure 2 As shown, this embodiment is based on the first embodiment, the grinding place i facing the edge of the ceramic tile h in the dust cover c is provided with a blowing port j, and the blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com