Automobile part grinding sheet

A technology of auto parts and grinding discs, which is applied in the direction of abrasive materials, metal processing equipment, manufacturing tools, etc., can solve the problems of poor finishing quality, low service life, and high labor intensity, and achieve large grinding volume, excellent effect, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment:

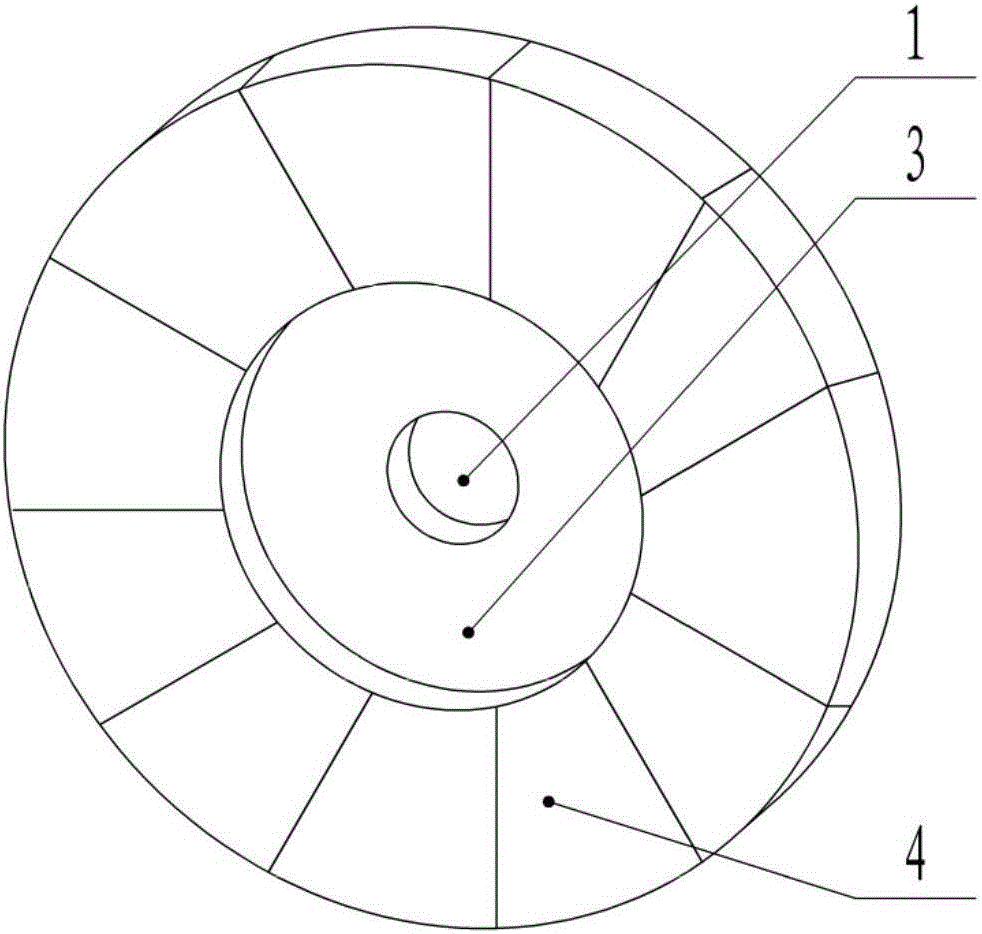

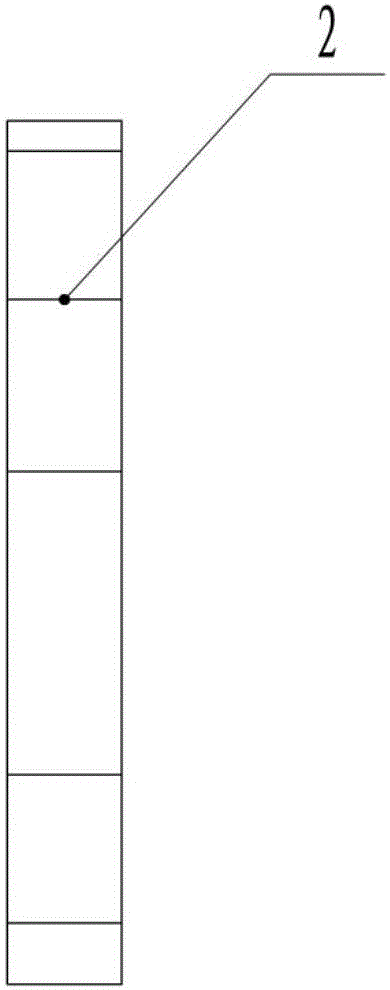

[0013] A polishing sheet for auto parts, comprising a polishing sheet main body 4 and an infrastructure layer 3, characterized in that the polishing sheet main body 4 is located outside the infrastructure layer 3, and the infrastructure layer 3 is provided with a circular groove, so The center of the infrastructure layer 3 is provided with a shaft hole 1 , the axis hole 1 is the same as the axis of the circular groove of the infrastructure layer 3 , and a plurality of grinding racks 2 are fitted on the outer periphery of the grinding sheet main body 4 .

[0014] The grinding rack 2 is made of brown corundum.

[0015] The thickness range of the grinding sheet main body 4 is 12-18mm.

[0016] The invention has the advantages of convenient installation, low cost, large grinding amount, improved work efficiency, and reduced noise. By using the grinding rack 2 made of brown corundum, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com