Grinding method for roll groove profile of chain riveting head machine

The technology of riveting head machine and roller is applied in the grinding field of the roller groove shape of chain riveting head machine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

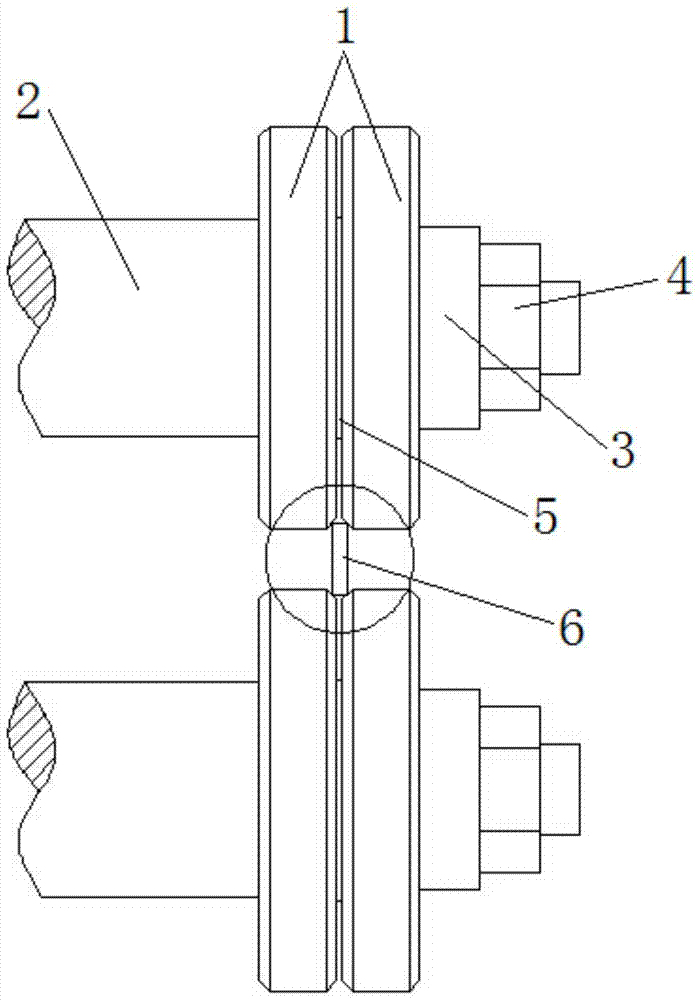

[0028] combine Figure 1 to Figure 3 As shown, a kind of grinding method of the roll groove profile of the chain riveting head machine of the present embodiment comprises the following steps:

[0029] (a) When the chain riveting machine does not remove the rolls, start the riveting machine so that the main shaft 2 drives the upper and lower sets of rolls to rotate. The speed of the main shaft 2 is the speed of the chain riveting machine when it is empty, and no additional adjustment is required; It should be noted that the chain riveting head machine itself should be installed firmly, and the rolls should run without jumping;

[0030] (b) Select an electric grinder equipped with a thin grinding wheel and turn it on;

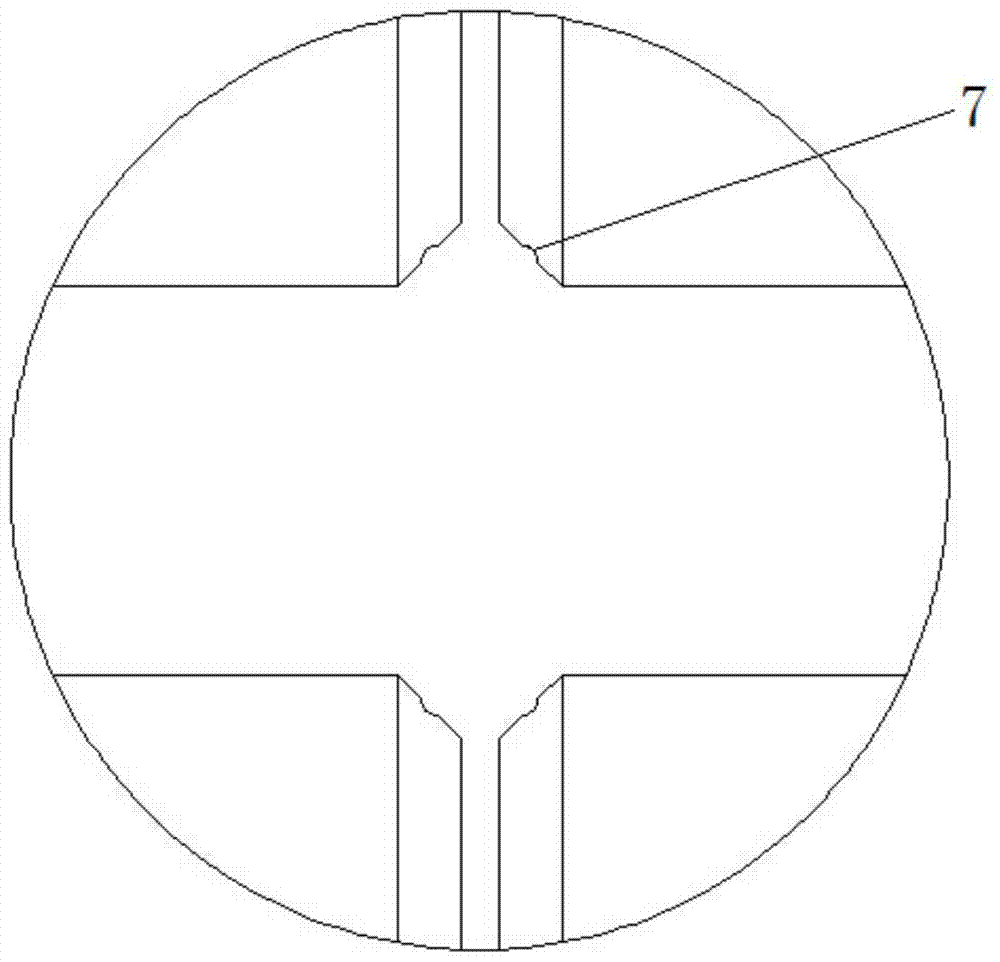

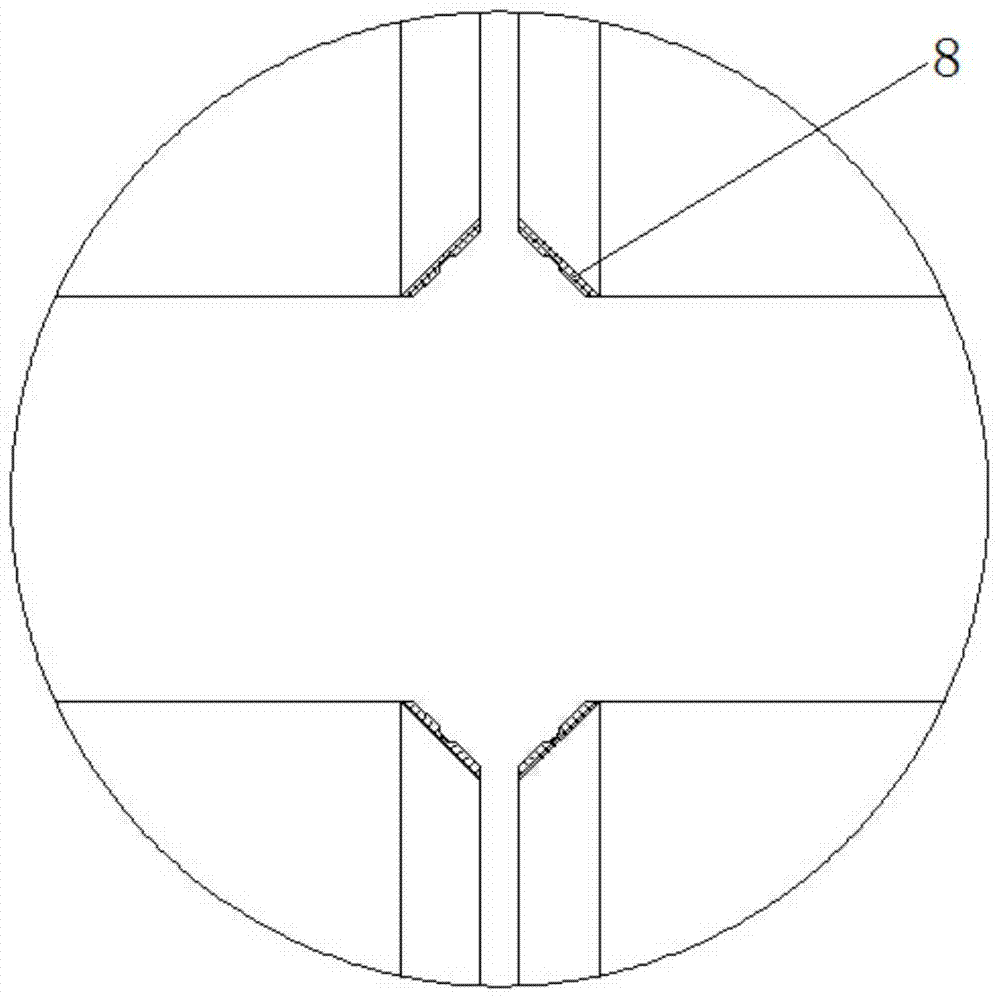

[0031] (c) Slowly approach the V-shaped groove 5 of the roll from the left or right side of the high-speed rotating emery wheel sheet, and adjust the grinding wheel sheet and one side of the V-shaped groove 5 according to the angle of the V-shaped groove 5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com