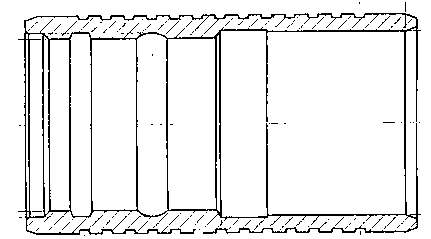

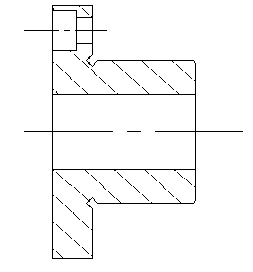

Technology for machining roller bearing outer ring for drafting system of textile machine

A technology of bearing outer ring and processing technology, applied in the field of bearing outer ring processing, can solve the problems of difficulty in correction and small grinding amount, and achieve the effects of reducing errors, improving self-rotation, and improving the accuracy of vertical difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0040] The present invention provides a processing technology for the outer ring of the roller bearing used in the drafting system of the textile machine, boldly explores and updates the process, improves the structure of the fixture, and selects the best process parameters. In the case of a poor process requirement of 0.005mm, the product can still have a compliance rate of 97%.

[0041]As a specific embodiment of the present invention, the present invention provides a processing technology for the outer ring of the roller bearing used in the drafting system of the textile machine, including the following processing flow, turning the blank - heat treatment - rough grinding the outer circle - rough grinding the end face - fine grinding the outer circle - fine grinding end face - final grinding outer circle - final grinding end face - super fine grinding outer circle - g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com