Mechanical type numerical control double-shaft turntable device

A two-axis turntable, mechanical technology, applied in metal processing equipment, metal processing machinery parts, large fixed members, etc., can solve the problem of single-tooth meshing side clearance cannot be adjusted, worm drive backlash is large, tooth surface gluing, etc. problem, to achieve the effect of preventing foreign matter from entering the transmission mechanism, maintaining good precision and eliminating backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be described in further detail below in conjunction with specific embodiments.

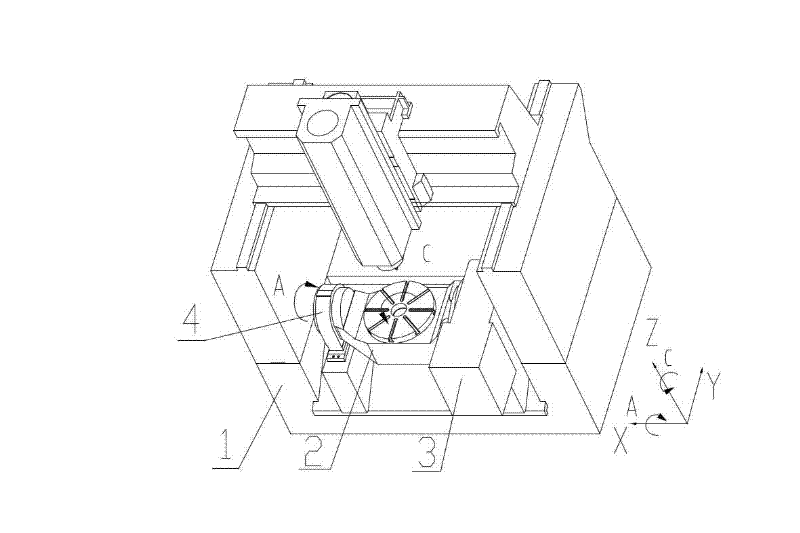

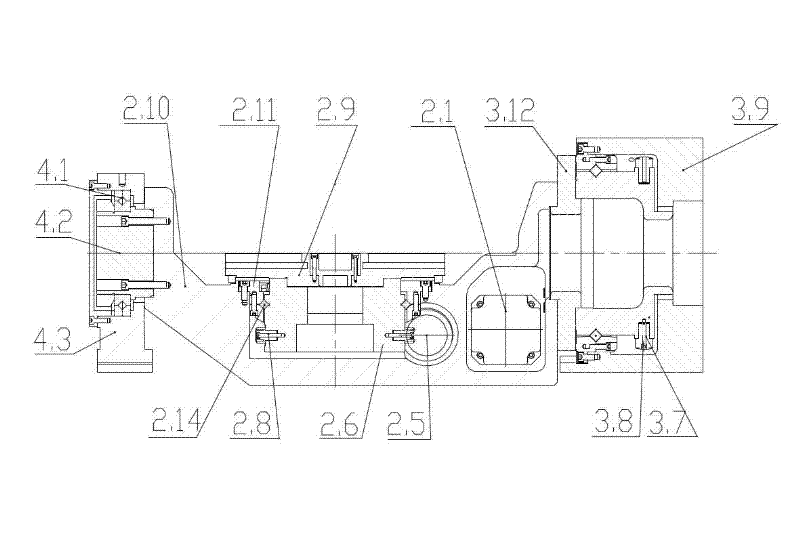

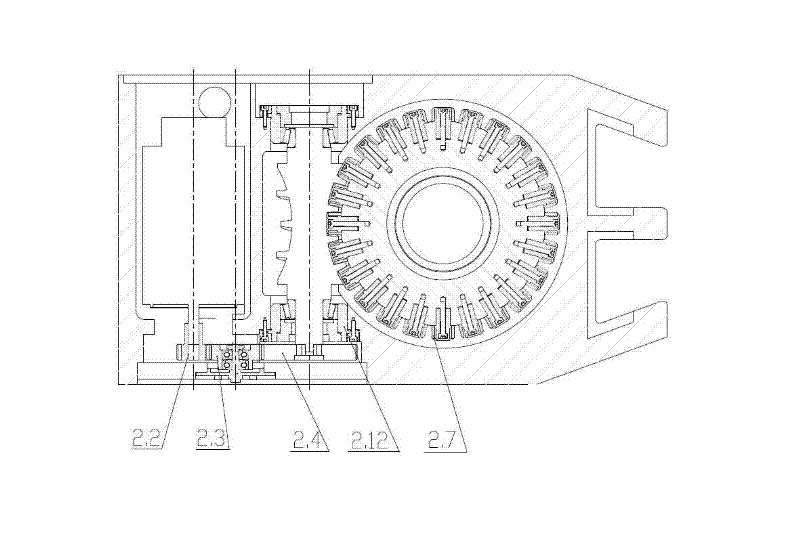

[0017] The mechanical CNC double-axis turntable includes the turntable C-axis 2, the A-axis drive end 3, and the A-axis support end 4, which are fixed on the bed 1 of the machining center by screws. The two ends of the C-axis 2 of the turntable are fixed on the A-axis support end 4 and the A-axis drive end 3 respectively by cooperating with the A-axis hole shaft and locked by screws; the A-axis support end 4 and the A-axis drive end 3 rotatably support the turntable C-axis 2, wherein the support end 4 of A-axis is fixed on the support seat 4.3 by the outer ring of cross roller bearing 4.1, the inner ring of cross roller bearing 4.1 is locked by a lock nut, and the inner ring of cross roller bearing 4.1 cooperates with shaft 4.2 Rotation, the 4.1 axis of the cross roller bearing is matched with the hole of the C-axis box of the turntable, the C-axis box 2.10 of the turntab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com