High-precision micro-miniature air static-pressure rotary table

An aerostatic, micro-miniature technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of high precision requirements and dynamic balance, many components, large height and size, etc., to achieve high rotation Accuracy, fewer numbers, and improved intersection spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

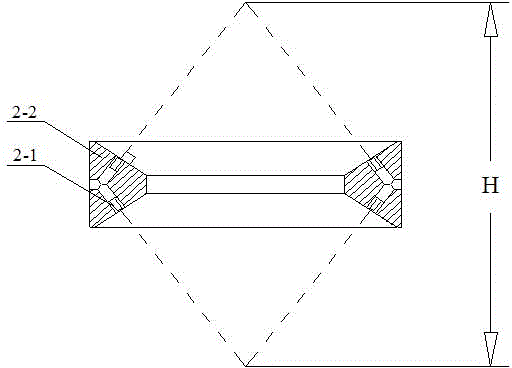

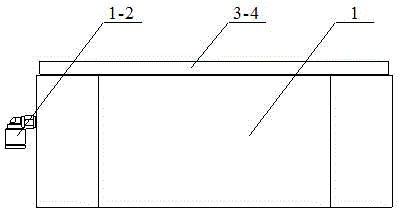

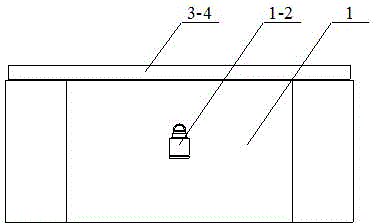

[0020] Such as Figure 1~Figure 7 As shown, a high-precision miniature aerostatic turntable involved in this embodiment includes: a turntable base 1, a conical air bearing sleeve 2, a spindle system 3 and a turntable motor 4), the turntable base 1 It includes a base 1-1, an air intake valve 1-2, an encoder cover plate 1-3 and a sealing ring 1-4; the conical air bearing sleeve 2 includes a restrictor 2-1 and an air bearing sleeve 2- 2. The spindle system 3 includes a lower conical air bearing spindle 3-1, a gap adjustment pad 3-2, an upper conical air bearing spindle 3-3 and a workbench 3-4; the turntable motor 4 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com