Gapless transmission device of numerical control contour grinder

A transmission device, a gap-free technology, applied in the field of grinding machine parts, can solve the problems of high energy consumption, short precision life, large space occupation, etc., and achieve the effects of smooth transmission, elimination of meshing gaps, and good precision retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

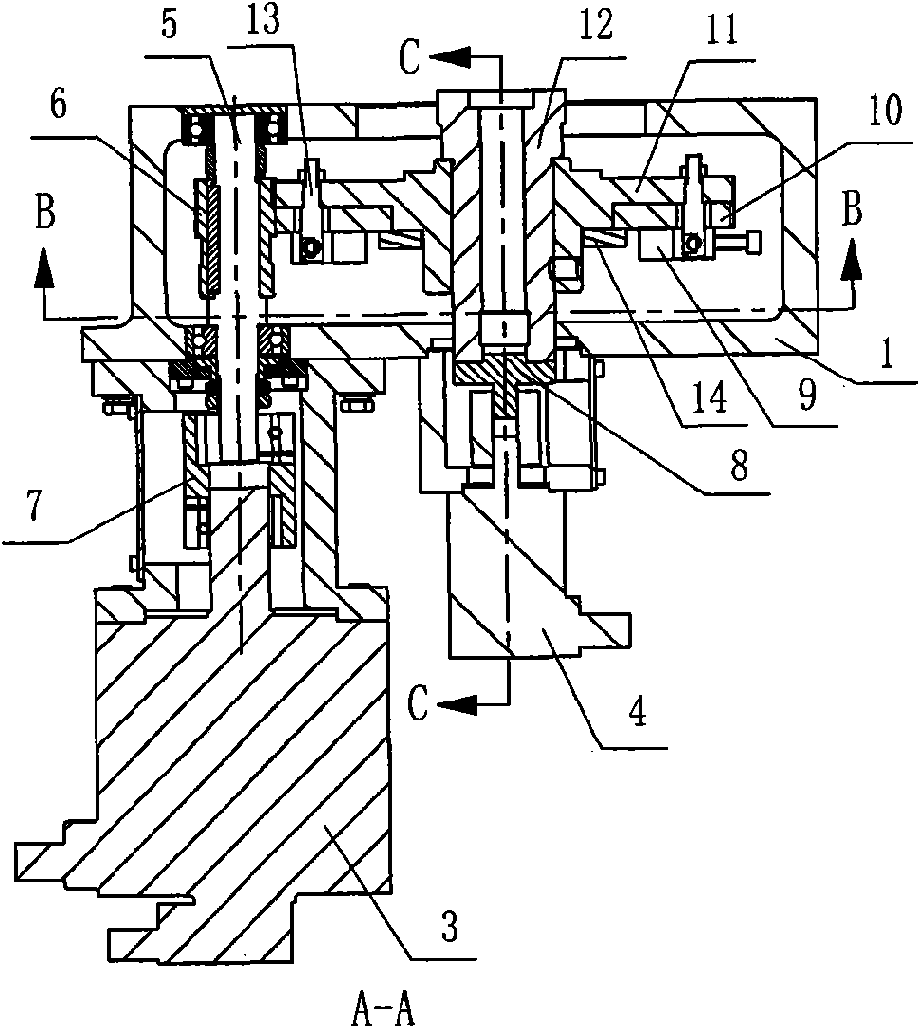

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

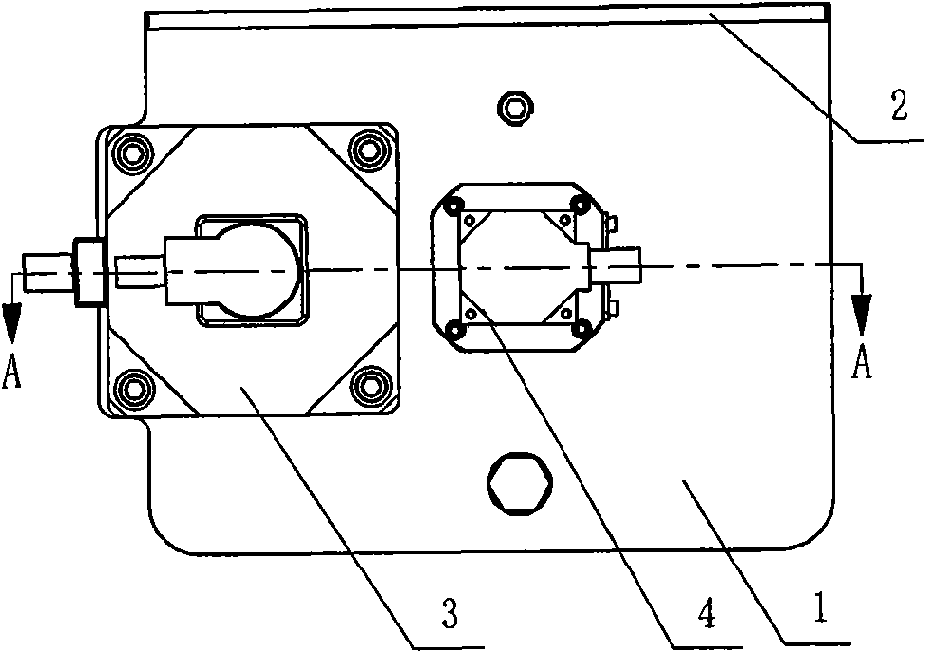

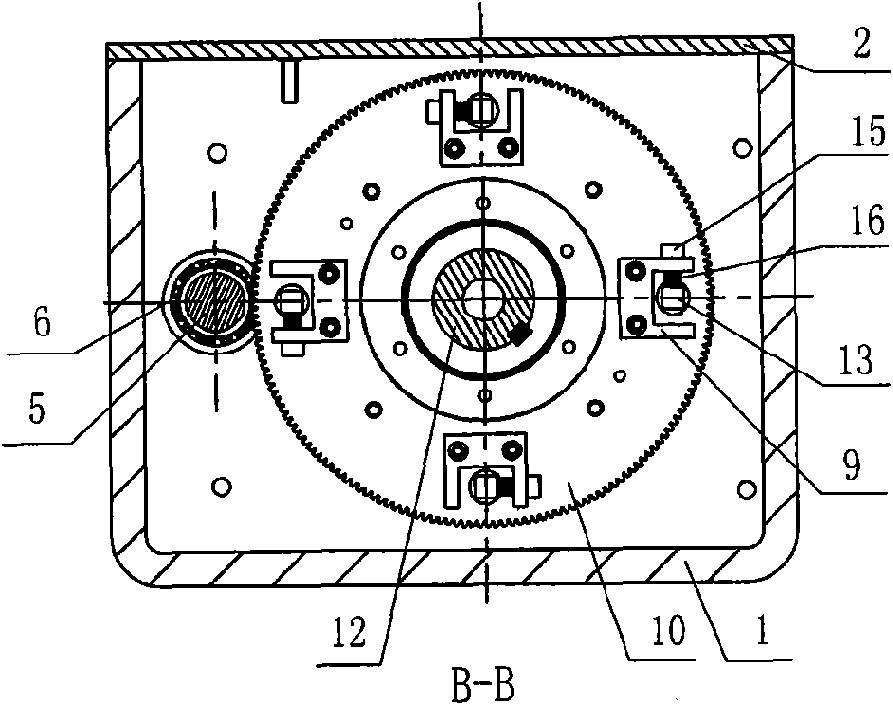

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention adopts the form of a gearbox, including a gearbox casing 1, a case cover 2, a motor 3 and an encoder 4, the casing 1 is provided with a rotating shaft 5 as a driving shaft and a main shaft 12 as a driven shaft, and the rotating shaft Bearing is arranged between 5 and the main shaft 12 and the box body 1, and the spur pinion 6 is fixedly set on the rotating shaft 5, and the spur gears 10 and 11, which are all meshed with the pinion 6, are set on the main shaft 12, wherein the bull gear 11 It is fixed with the main shaft 12, and one side of the big gear 11 is provided with a cylindrical bush connected with it as a whole. The diameter of the bush is larger near the abutting end face to form a stepped end face. The big gear 10 is set on the bush, and The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com