Laying head using dynamic-static pressure oil film bearing

An oil film bearing, dynamic and static pressure technology, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve problems that are not conducive to mechanical installation and maintenance disassembly, contact between rotor and oil film bearing, trivial design, etc., to achieve good precision Retention, strong load capacity, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

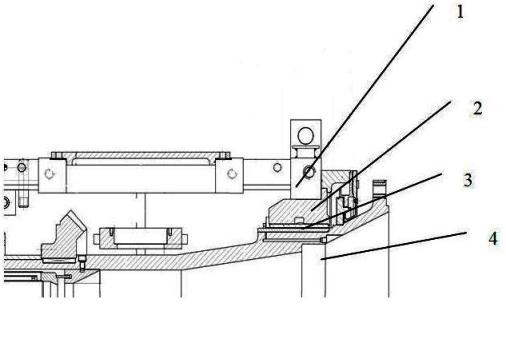

[0018] like figure 1 As shown, a laying machine using dynamic and static pressure oil film bearings, the rotor (4) is fixed on the support structure (1) through the dynamic and static pressure oil film bearing device (3) and the support bearing (2), and the rotor (4) is driven by external force Drive other parts of the spinning head of the spinning disc to work to complete the spinning process.

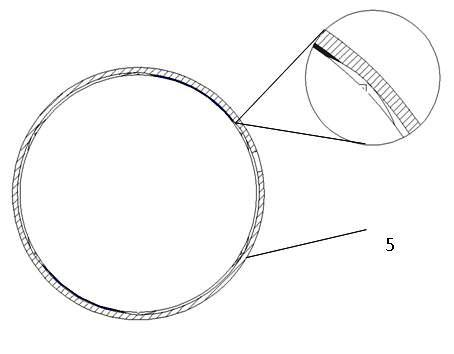

[0019] like figure 2 As shown, the oil film bearing (5) is an integral annular design, which is integrally formed in the process of processing, and has high rigidity and high load-carrying capacity. The hydrostatic oil film bearing device (3) is composed of an oil film bearing (5) and a cavity formed between the oil film bearing (5) and the rotor (4).

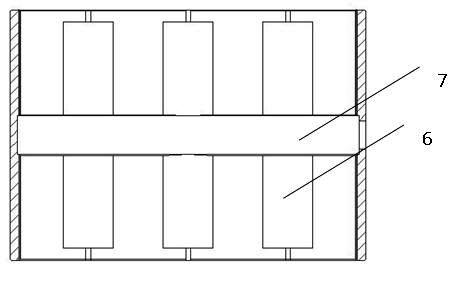

[0020] like image 3 As shown, six grooves (6) are evenly distributed on the inner side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com