Continuous no-impact automatic uniform-load press-fitting device

A press-fitting device and self-equalizing technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to locate and align workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

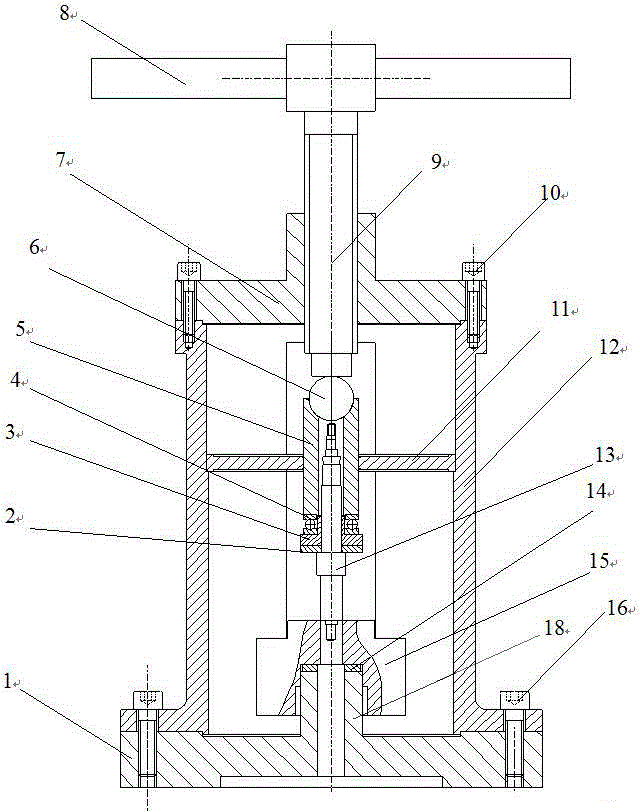

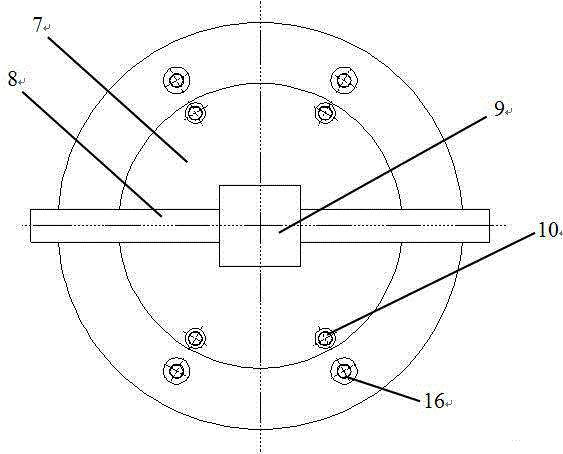

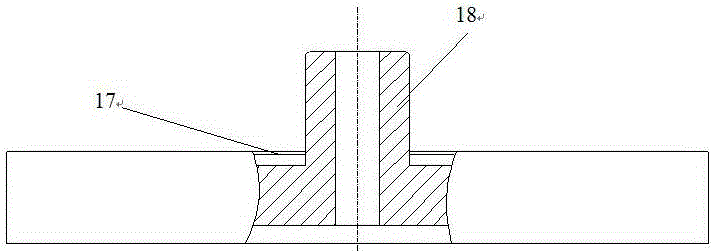

[0026] figure 1 It is a structural schematic diagram of a continuous non-impact self-equalizing press-fitting device of the present invention, figure 2 It is a top view of the continuous non-impact self-equalizing press-fitting device of the present invention, image 3 It is a sectional view of the base in the present invention, Figure 4 It is a sectional view of the gland in the present invention, Figure 5 It is a sectional view of the support cylinder in the present invention, Image 6 It is a sectional view of the guide plate in the present invention. exist Figure 1~6 Among them, the continuous non-impact self-equalizing press-fitting device of the present invention includes a base 1, a press-fitting washer 2, a bearing support sleeve 3, a thrust ball bearing 4, a sleeve 5, a steel ball 6, a gland 7, and a rotating rod 8 , Drive screw 9, guide plate 11, support cylinder 12, shaft 13, hole 15, support washer 14. The center of the base 1 is provided with an annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com