Automatic lining placing machine

A lining, automatic technology, applied in packaging and other directions, can solve the problems of high labor cost and labor intensity of workers, and achieve the effect of high production efficiency, good versatility, and avoidance of clutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

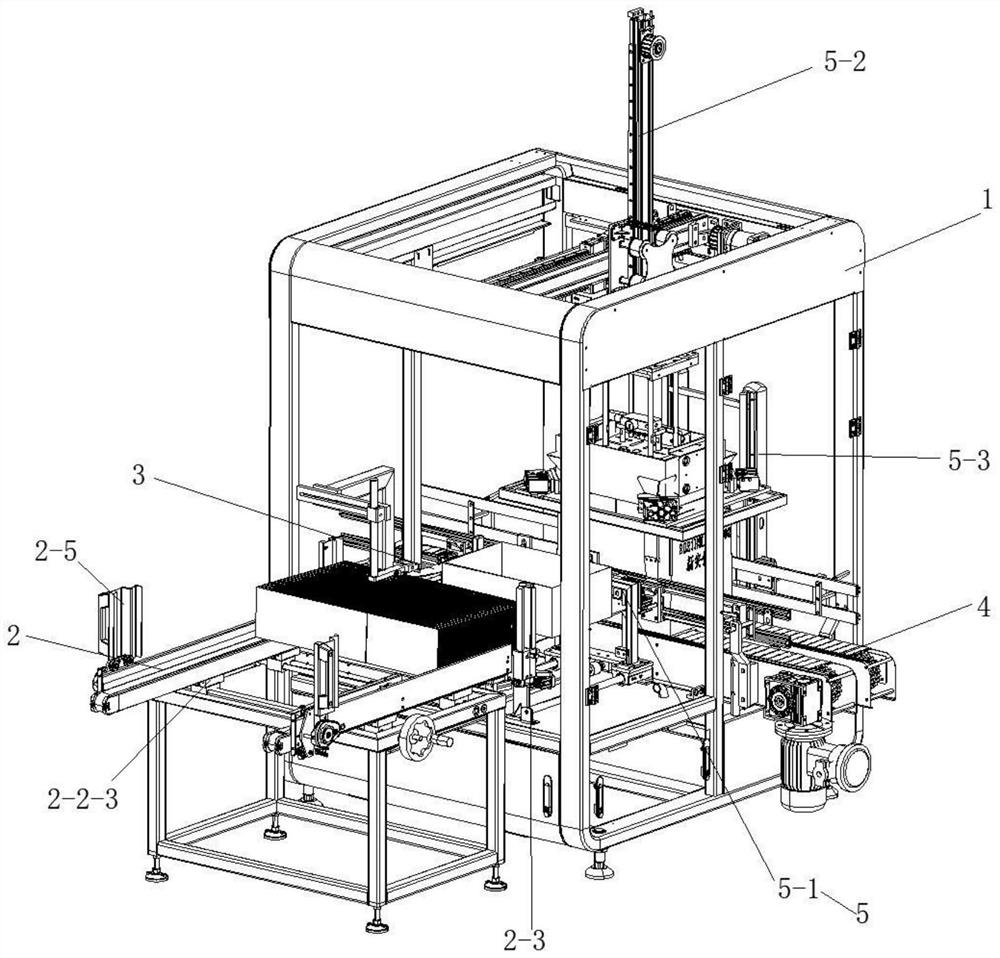

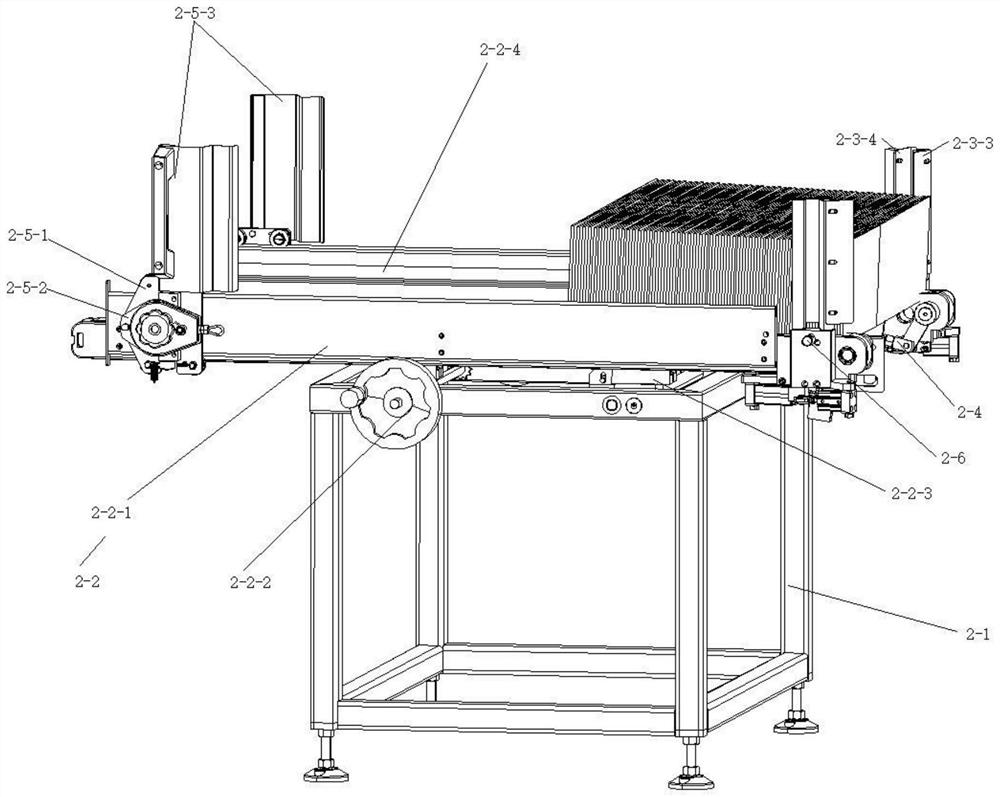

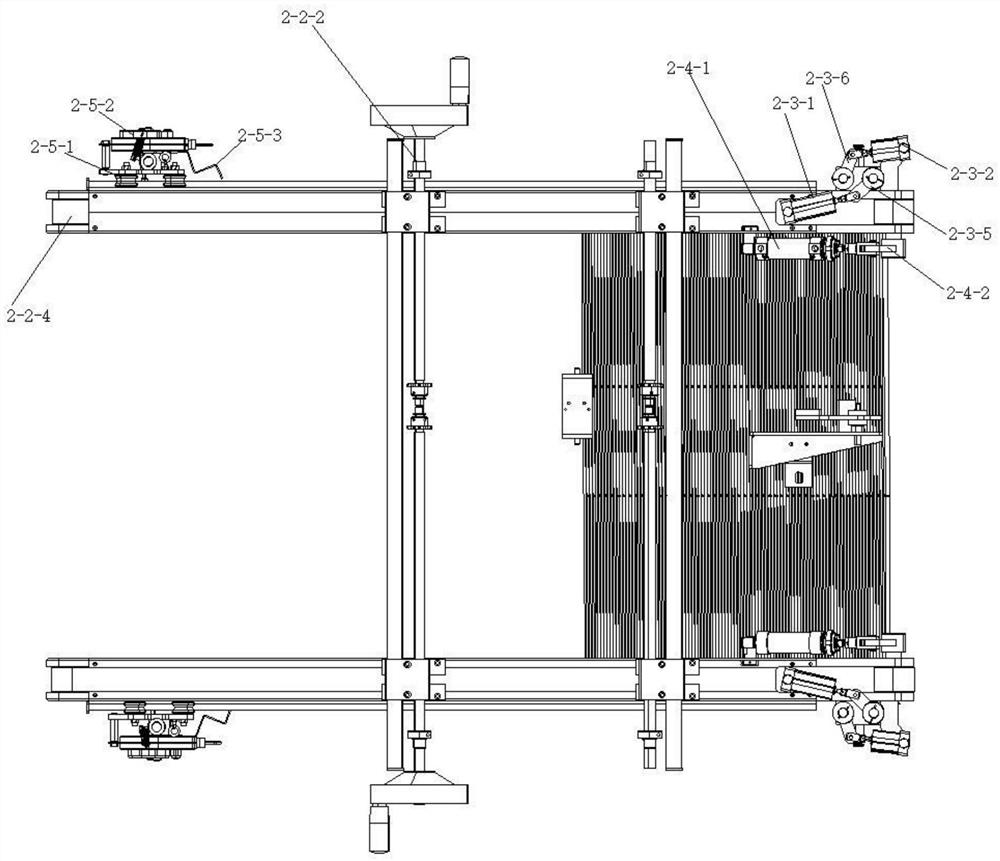

[0050] Such as Figure 1 to Figure 9 The shown automatic lining machine includes a first frame 1, a lining feeding mechanism 2, a lining folding mechanism 3, a carton conveying mechanism 4 and a lining placing mechanism 5, wherein the lining folding mechanism 3, the carton conveying mechanism 4 and the lining placement mechanism 5 are all installed on the first frame 1, and the lining feeding mechanism 2 is located on the left side of the first frame 1. The lining folding mechanism 3 is located at the output end of the lining feeding mechanism 2, and is used to automatically fold the flat-shaped lining incoming material on the lining feeding mechanism 2 into a frame structure, and the lining placing mechanism 5 is used to fold the frame-shaped The inner liner is placed in the carton conveyed by the carton conveying mechanism 4, the whole process does not require manual operation, the production efficiency is high, the labor cost of the enterprise is reduced, and the economic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com