Step and stepless regulation device and regulation method for eccentricity of eccentric shaft

A technology of stepless adjustment and eccentricity, applied in the direction of fluid using vibration, etc., can solve the problems that the eccentricity cannot be adjusted arbitrarily, the mechanism is complicated, and the cost is high, so as to avoid the influence of human factors, simple and fast operation, and good accuracy retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

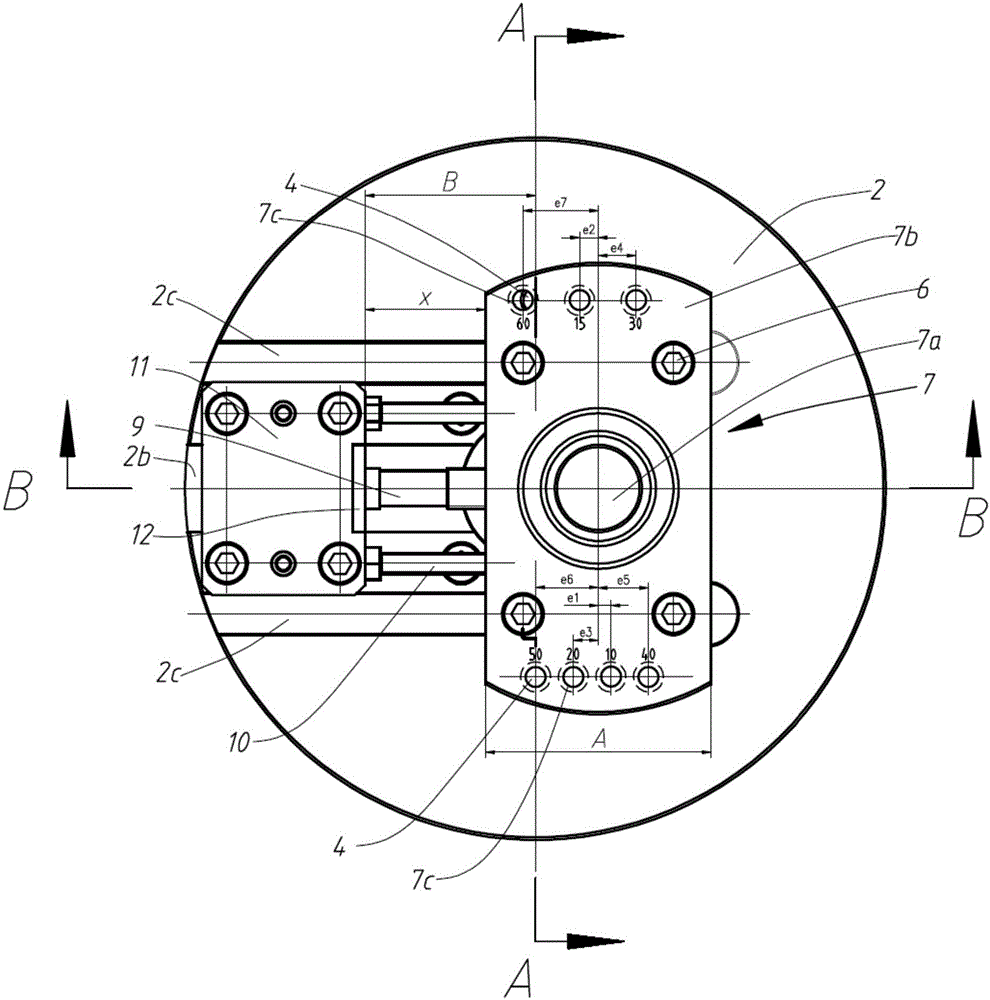

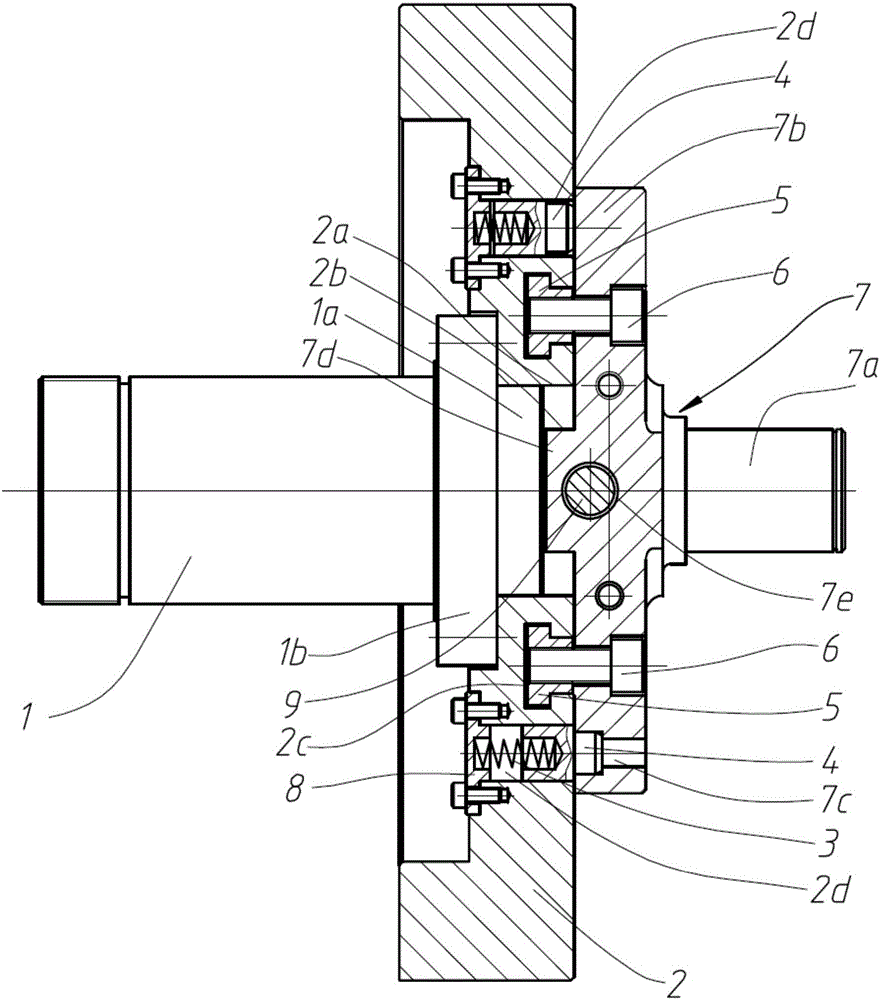

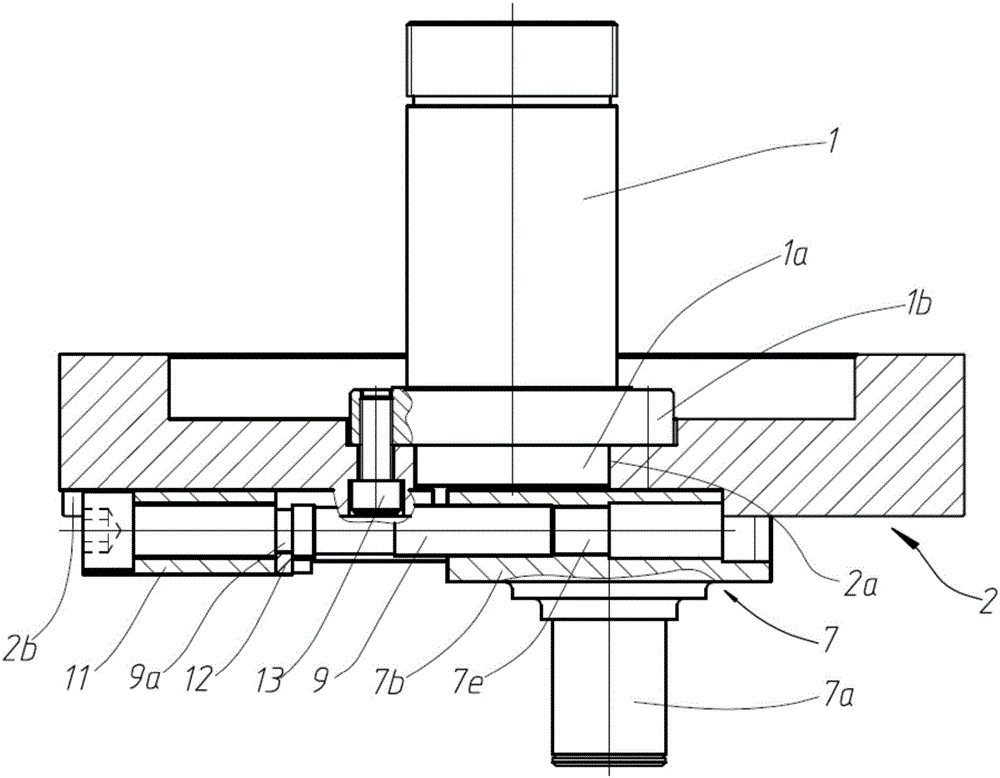

[0022] The technical solution of the present invention will be further specifically described below by taking the eccentric shaft vibration excitation device used in the vehicle shock absorber test bench of the present invention as a specific embodiment, and in conjunction with the accompanying drawings.

[0023] The meanings of "inside and outside" in the present invention refer to that relative to the device itself, the direction pointing to the inside of the device is inward, and vice versa, it is not a specific limitation to the device mechanism of the present invention.

[0024] The meaning of "up and down" described in the present invention refers to: "up" refers to the position at a high place, which is opposite to "down", that is, the upper side; "down" refers to the position at a low place, and " "Up" is relative, that is, the lower layer. Rather than a specific limitation on the mechanism of the device of the present invention.

[0025] The meaning of "left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com