Automatic testing device of performance of electromagnet for valve

An automatic testing device and electromagnet technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the need for large-scale testing of electromagnets that are not suitable for valves, increase the labor intensity of testers, and affect the testing speed of electromagnets, etc. problem, to achieve the effect of fast test speed, simple structure, and avoiding the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

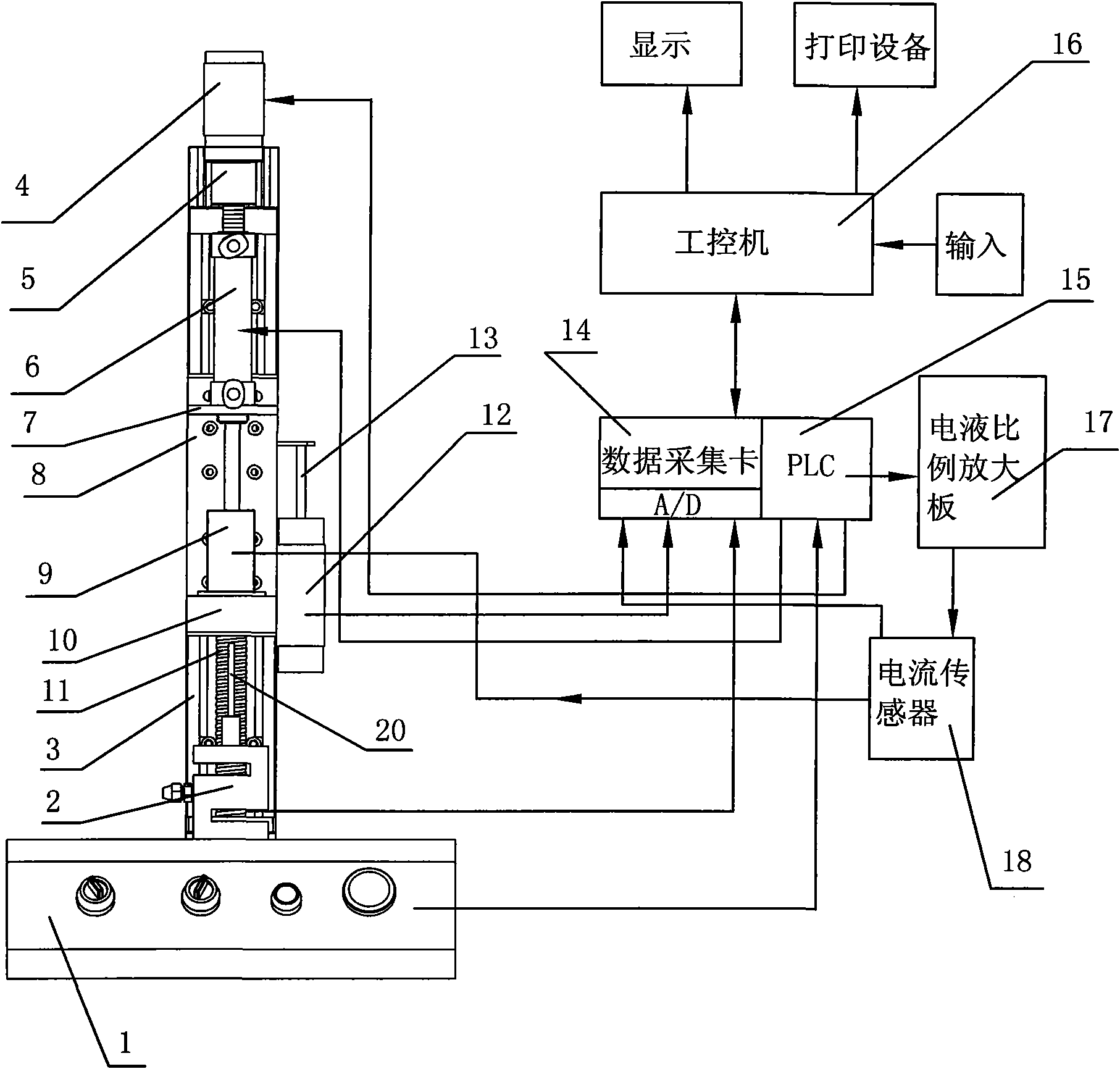

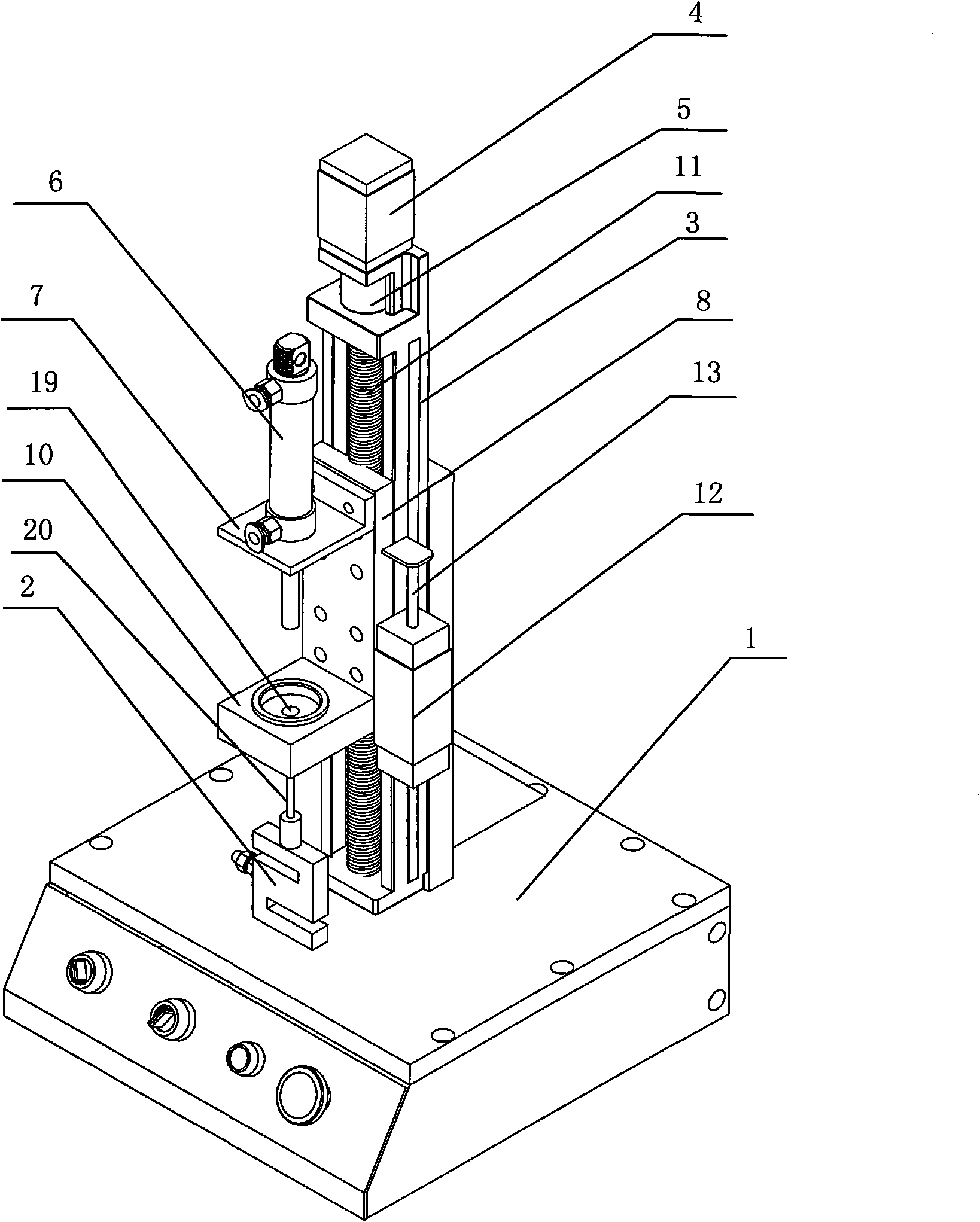

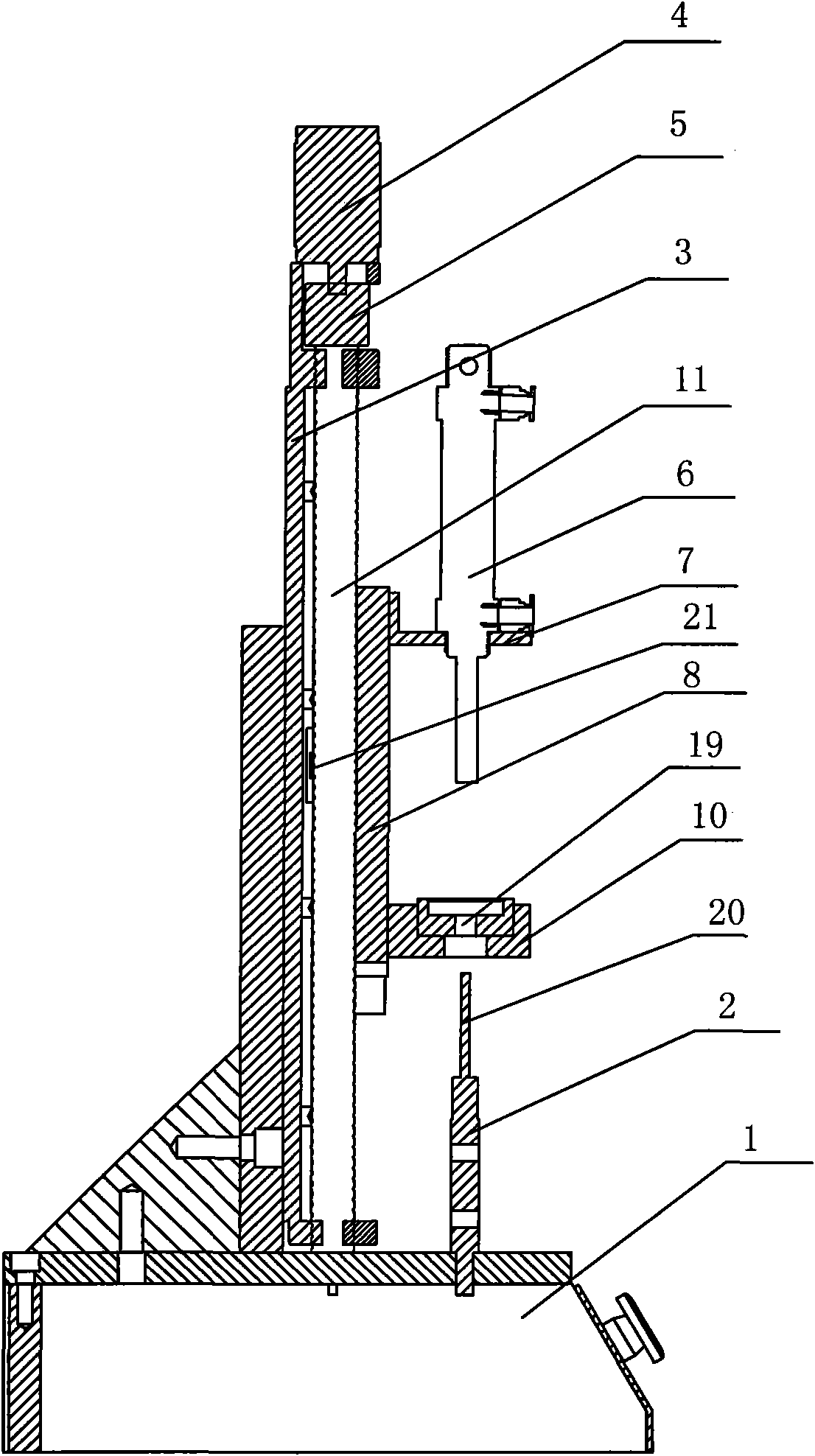

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] Such as figure 1 , figure 2 and image 3 shown.

[0018] The valve electromagnet performance automatic testing device of the present invention comprises a workbench 1, a tension pressure sensor 2, a displacement sensor 12, an electro-hydraulic proportional amplifying plate 17, and it also includes a slide block 8 and a linear slide table fixedly connected to the workbench 1. 3. The electromagnet 9 to be tested is placed and fastened on the slider 8, and the slider 8 slides and fits vertically along the linear slide 3, and the tension and pressure sensor 2 is fixed on the workbench 1 below the slider 8, And the contact rod 20 of the pull pressure sensor 2 is located directly below the armature of the electromagnet 9 to be tested, the displacement sensor 12 is fixedly connected on the linear slide table 3, and the free end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com