Flawless proton exchange membrane directly coated with catalyst as well as preparation method and application of flawless proton exchange membrane

A proton exchange membrane and catalyst technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as uneven wet coating thickness, affecting the morphology of the catalytic layer, cracks in the catalytic layer, etc., to reduce the interlayer interface. Risk, effect of increasing catalytic layer efficiency, compressing coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a flawless catalyst directly coating a proton exchange membrane, comprising the following steps:

[0040] (1) Perfluorosulfonic acid solution, n-propanol, and deionized water are mixed to obtain a dispersion;

[0041] (2) The catalyst is wetted with deionized water, then mixed with the dispersion obtained in step (1), and subjected to ultrasonic dispersion treatment to form a primary dispersed catalyst slurry;

[0042] (3) carrying out high-shear dispersion to the primary dispersed catalyst slurry obtained in step (2), to obtain secondary dispersed catalyst slurry;

[0043] (4) Using a knife coating process, the secondary dispersed catalyst slurry obtained in step (3) is coated in a single layer to obtain a flawless catalyst directly coated with a proton exchange membrane.

[0044] In one embodiment of the present invention, in step (1), the mass percent concentration of the perfluorosulfonic acid solution is 5-25%.

[004...

Embodiment 1

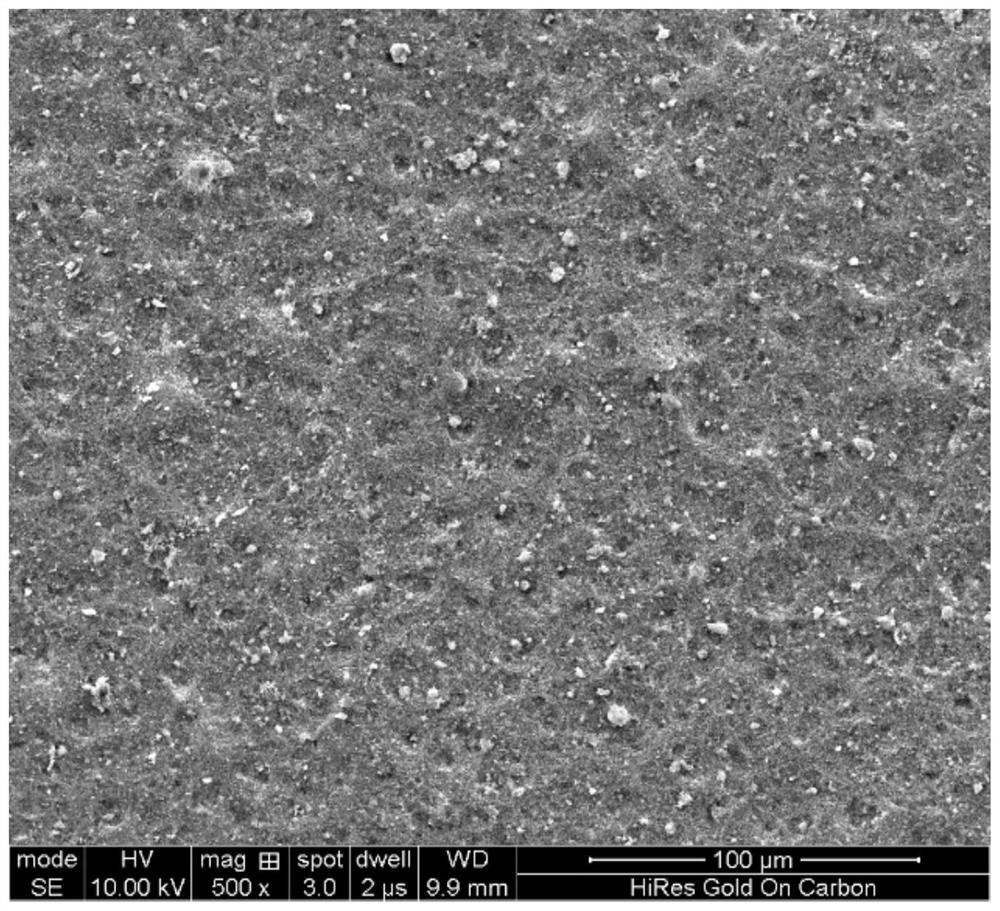

[0059] This example provides a flawless catalyst directly coated proton exchange membrane and its preparation method.

[0060] (1) Perfluorosulfonic acid solution, n-propanol, and deionized water are mixed to obtain a dispersion; wherein, perfluorosulfonic acid solution is a Nafion solution whose mass concentration is 25%, and the volume ratio of n-propanol and deionized water is 1:1.

[0061] (2) the Pt / C catalyst (the mass fraction of platinum in the catalyst is 40%) is wetted with a small amount of deionized water, then mixes with the dispersion liquid that step (1) obtains (perfluorosulfonic acid dry weight and catalyst in the dispersion liquid The mass ratio of the medium carbon carrier is 0.6:1), and ultrasonic dispersion treatment (water bath temperature is 17°C, ultrasonic frequency is 25kHz, ultrasonic power is 700W, ultrasonic time is 10min) to obtain a primary dispersed catalyst slurry with a solid content of 16%. material;

[0062] (3) The primary dispersed catal...

Embodiment 2

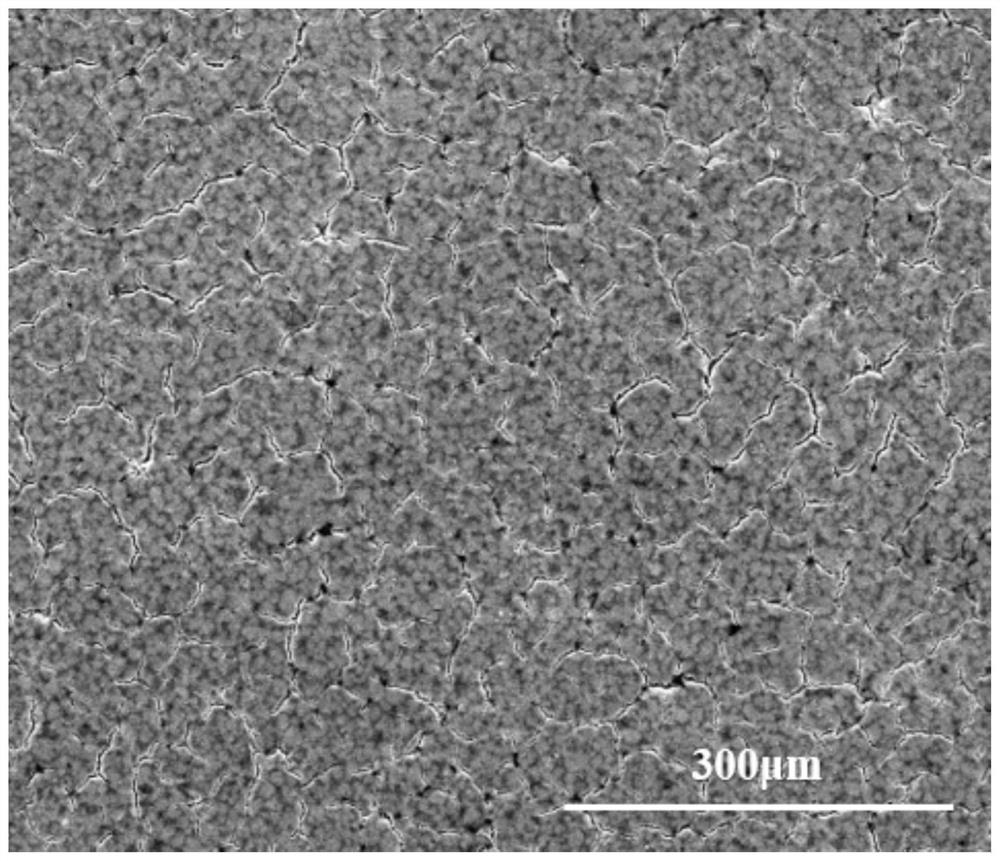

[0111] This example provides a flawless catalyst directly coated proton exchange membrane and its preparation method.

[0112] (1) Perfluorosulfonic acid solution, n-propanol, and deionized water are mixed to obtain a dispersion; wherein, perfluorosulfonic acid solution is a Nafion solution whose mass concentration is 25%, and the volume ratio of n-propanol and deionized water is 1:1.2.

[0113] (2) the Pt / C catalyst (the mass fraction of platinum in the catalyst is 40%) is wetted with a small amount of deionized water, then mixes with the dispersion liquid that step (1) obtains (perfluorosulfonic acid dry weight and catalyst in the dispersion liquid The mass ratio of the medium carbon carrier is 1:1), and ultrasonic dispersion treatment (water bath temperature is 15°C, ultrasonic frequency is 50kHz, ultrasonic power is 1000W, ultrasonic time is 3min) to obtain a primary dispersed catalyst slurry with a solid content of 5%. material;

[0114] (3) Use the stator-rotor mixer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com