Bacillus subtilis and method for preparing milk-flavor cordyceps sinensis fermentation liquor by using bacillus subtilis

A technology of Bacillus subtilis and Cordyceps sinensis is applied in the field of microorganisms to achieve the effects of low production cost, low yield and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Screening and isolation of embodiment 1 bacterial strain

[0050] Sampling: In a sterile operating bench, weigh 20g of Maotai-flavored Daqu by quartering method. After grinding the sample with a mortar, wash it with 180mL of normal saline, shake the incubator at 150rpm and mix for 30min.

[0051] Bacteria enrichment culture: after the water bath, absorb 5 mL of koji solution and inoculate it into the enrichment medium, and enrich the culture in a shaker at 37°C and 150 rpm for 24 hours.

[0052] Dilution and coating: after enrichment culture, pipette 1mL of bacterial suspension into a 9mL saline test tube to dilute. Pipette 100 μL to dilute to 10 -4 、10 -5 、10 -6 The bacterial suspension was spread on the plate isolation medium.

[0053] Isolation: Cultivate in a 37°C incubator for 24 hours, observe the colony shape after the cultivation, pick a single colony and inoculate it on the plate medium by streaking method to separate and purify.

[0054] For the specific...

Embodiment 2

[0055] Example 2 Fermentation method for the production of vanillin by bacterial strain biotransformation of glucose

[0056] S1: Inoculate the preserved bacterial strain on the activation medium, and culture it statically at 35-40° C. for 12-24 hours.

[0057] S2: After the seed medium is inoculated with the strain, it is cultured for 12-24 hours at a temperature of 35-40° C. and a rotation speed of 150 r / min to obtain a seed solution.

[0058] S3: After the glucose fermentation medium is inoculated with the seed solution, ferment for 100-150 hours under the culture conditions of a temperature of 35-40° C. and a rotation speed of 100-180 rpm.

[0059] Table 1 shows the activation medium and glucose fermentation medium required for the bioconversion of glucose to vanillin by the strain.

Embodiment 3

[0060] Example 3 strain producing vanillin ability test

[0061] In this experiment, the strains were preliminarily screened, and 19 strains with strong vanillin-producing ability were obtained. The specific results are shown in Table 2.

[0062] Table 2 Screening of higher yield strains

[0063]

[0064]

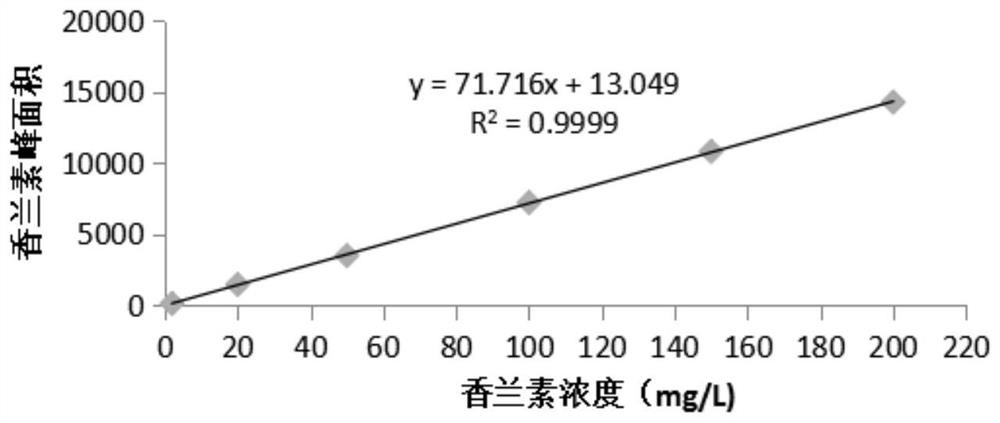

[0065] Take the vanillin content (x, mg / L) as the abscissa and OD280 (y) as the ordinate to draw the vanillin standard curve, see the results figure 1 . Depend on figure 1 It can be seen that the regression equation of the standard curve is y=71.716x+13.049, and the correlation coefficient R 2 = 0.9999. The vanillin content and the absorbance value showed a good linear relationship.

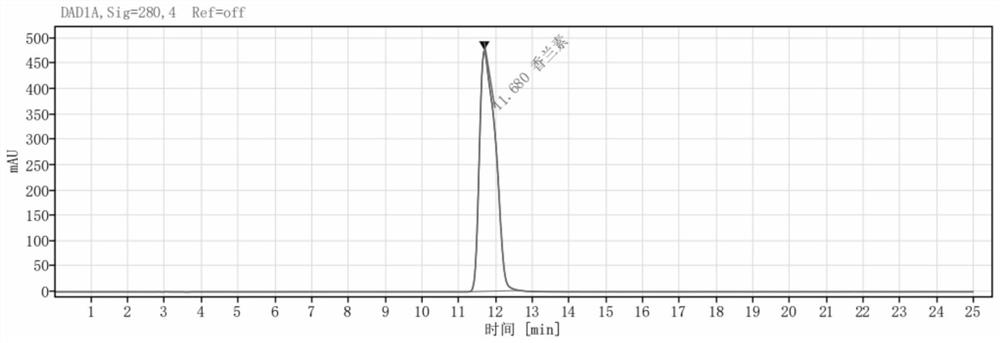

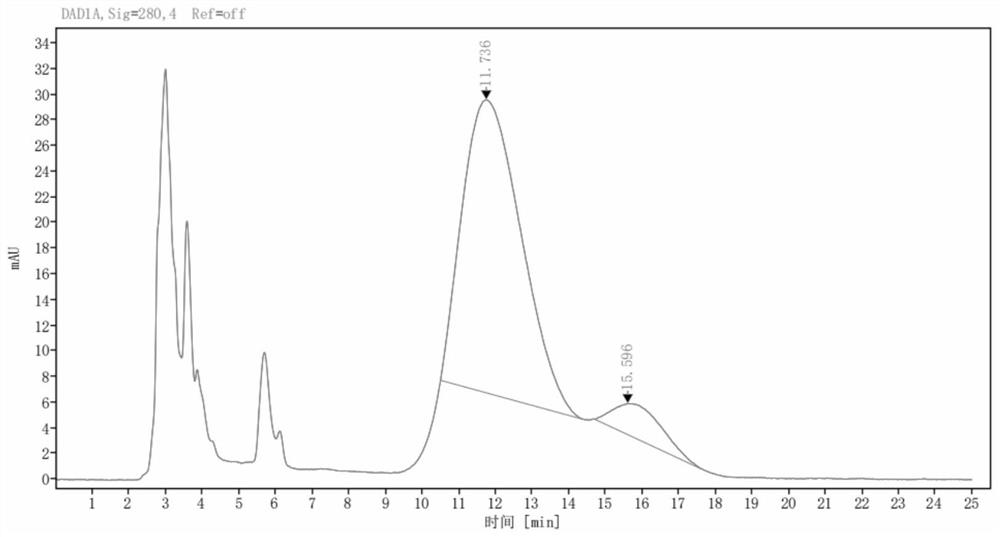

[0066] In this experiment, the HPLC detection of the vanillin standard was carried out with reference to the high-performance liquid chromatography method used by Zhao Jianfen et al. (05):332-333.). The resulting liquid chromatogram was figure 2 Shown, the retention time of vani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com