Method for biologically synthesizing natural aromadendrin by escherichia coli through utilizing naringenin

A technology of Escherichia coli and naringenin is applied in the field of fermentation engineering to achieve the effects of simple production process, low production cost and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Starting strain: the starting strain is Escherichia coli (E.coli) DHK-161114CCTCC NO:M 2016645.

[0031] Plate culture: Streak inoculate the Escherichia coli stored in the puncture tube onto the plate medium, and culture in a 30°C incubator for 15-24 hours.

[0032] Preparation of Escherichia coli CCTCC NO:M 2016645 strain bank: Pick a single colony, inoculate it into the seed medium, culture it on a shaker at 200 rpm for 13-17 hours at 30°C, absorb 0.5ml of the obtained seed culture solution and transfer it to 50% In the glycerol solution, prepare a seed glycerol tube with a final concentration of 25%, and store at -80°C.

[0033] Preparation of seed liquid: absorb 20 uL of seed glycerol tube, inoculate into seed medium, and culture at 30° C. with shaking at 200 rpm for 13 to 17 hours to obtain seed liquid.

[0034] Preparation of seed medium: peptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, prepared from tap water, pH adjusted to 7.2, sterilized by high pres...

Embodiment 2

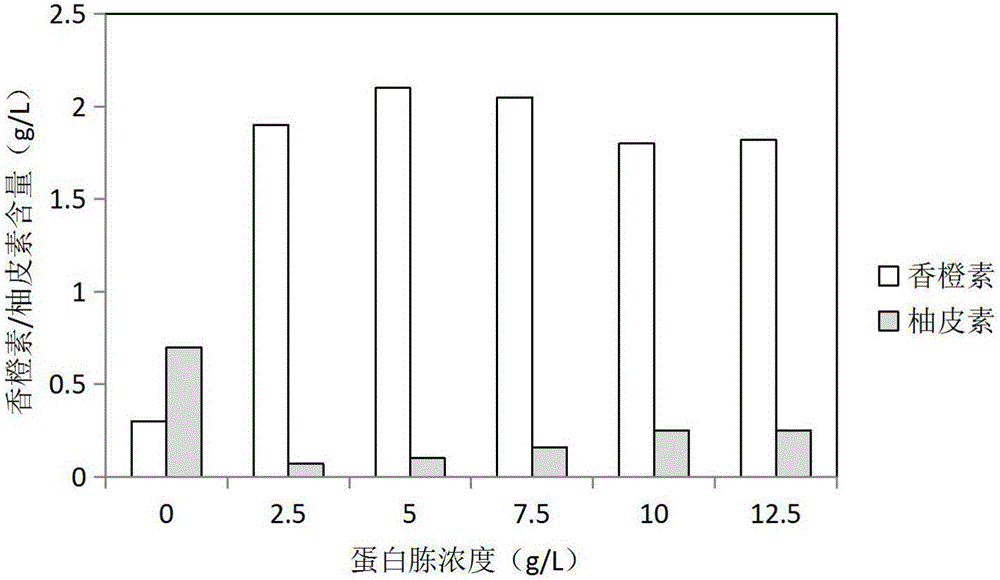

[0040] Embodiment 2 different peptone concentrations

[0041] Starting strain: the same as in Example 1.

[0042]Preparation of seed medium: same as in Example 1.

[0043] Preparation of fermentation medium: prepare peptone 0, 2.5, 5, 7.5, 10.0 and 12.5 g / L, yeast extract 5 g / L, sodium chloride 10 g / L, tap water, adjust pH to 7.2, and extinguish with high-pressure steam at 121 °C Bacteria 20min.

[0044] Pipette 20 μL seed glycerol tube into the seed shaker flask culture medium, the liquid volume is 50ml / 250ml, culture at 30°C, 200rpm shaker for 16h, and transfer to fermentation medium with different peptone concentrations according to 5% inoculum size (50ml / 250ml), under the condition of 37°C, 200rpm shaker shake culture for 3h, cool down to 30°C, add 1.5% lactose to induce 3h, maintain 30°C, add 2.7g / L substrate naringenin in total, fermentation time After 54h, the substrate and product content were measured after the fermentation was finished, and the results were shown ...

Embodiment 3

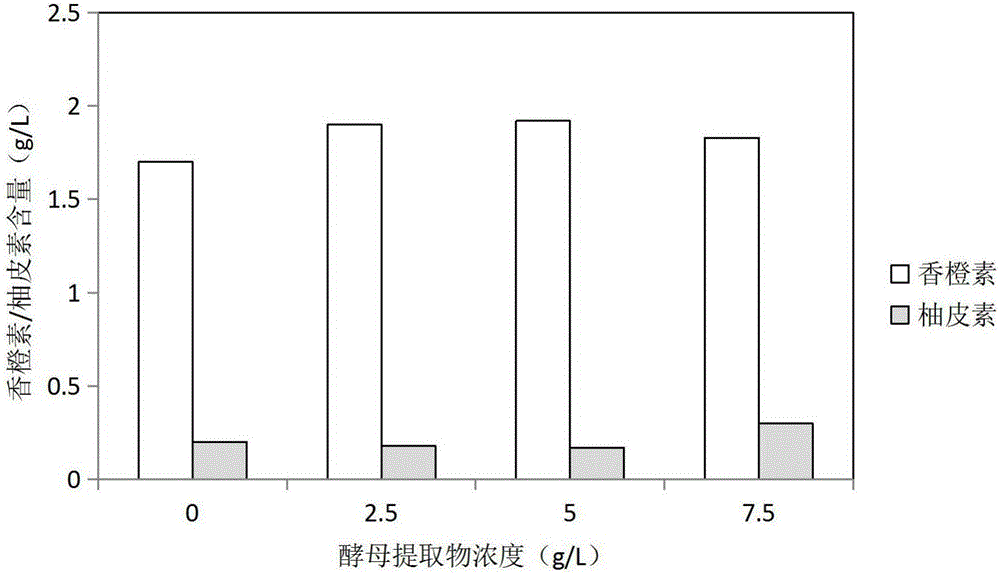

[0046] Embodiment 3 different yeast extract concentrations

[0047] Starting strain: the same as in Example 1.

[0048] Preparation of seed medium: same as in Example 1.

[0049] Preparation of fermentation medium: peptone 10g / L, yeast extract concentrations of 0, 2.5, 5.0 and 7.5g / L, sodium chloride 10g / L, tap water, pH adjusted to 7.2, sterilized by high pressure steam at 121°C for 20min .

[0050] Pipette 20 μL of seed glycerol tube into the seed shaker flask culture medium, the liquid volume is 50ml / 250ml, and culture at 30°C, 200rpm shaker for 16h, and transfer to fermentation culture with different yeast extract concentration according to 5% inoculum size Medium (50ml / 250ml), at 37°C, 200rpm shaker culture for 3h, cooled to 30°C, added 1.5% lactose for induction for 3h, maintained at 30°C, added 2.7g / L substrate naringenin in total, The fermentation time was 54h, and the substrate and product content were measured at the end of the fermentation. The results are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com