Squirrel cage motor rotor die casting device and method

A motor rotor and squirrel-cage technology, applied in the field of squirrel-cage motor rotor die-casting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

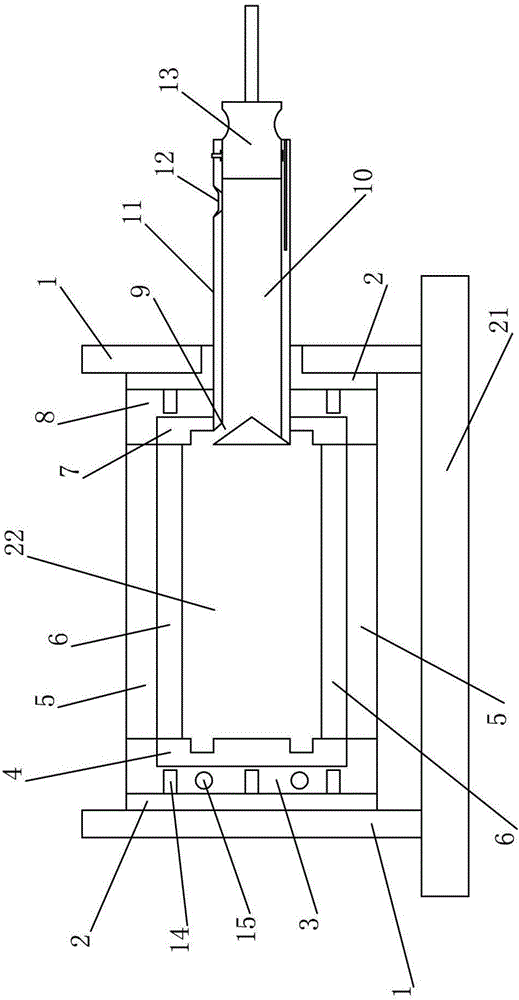

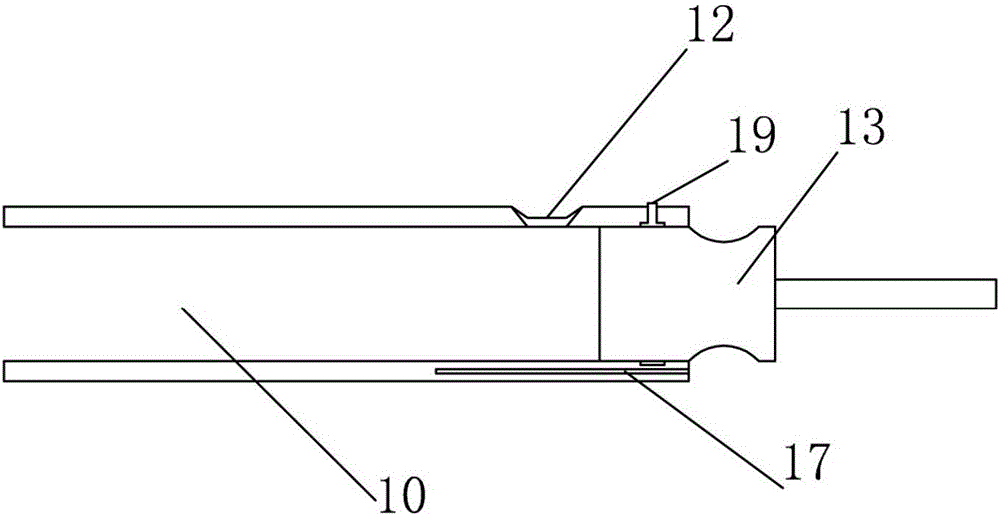

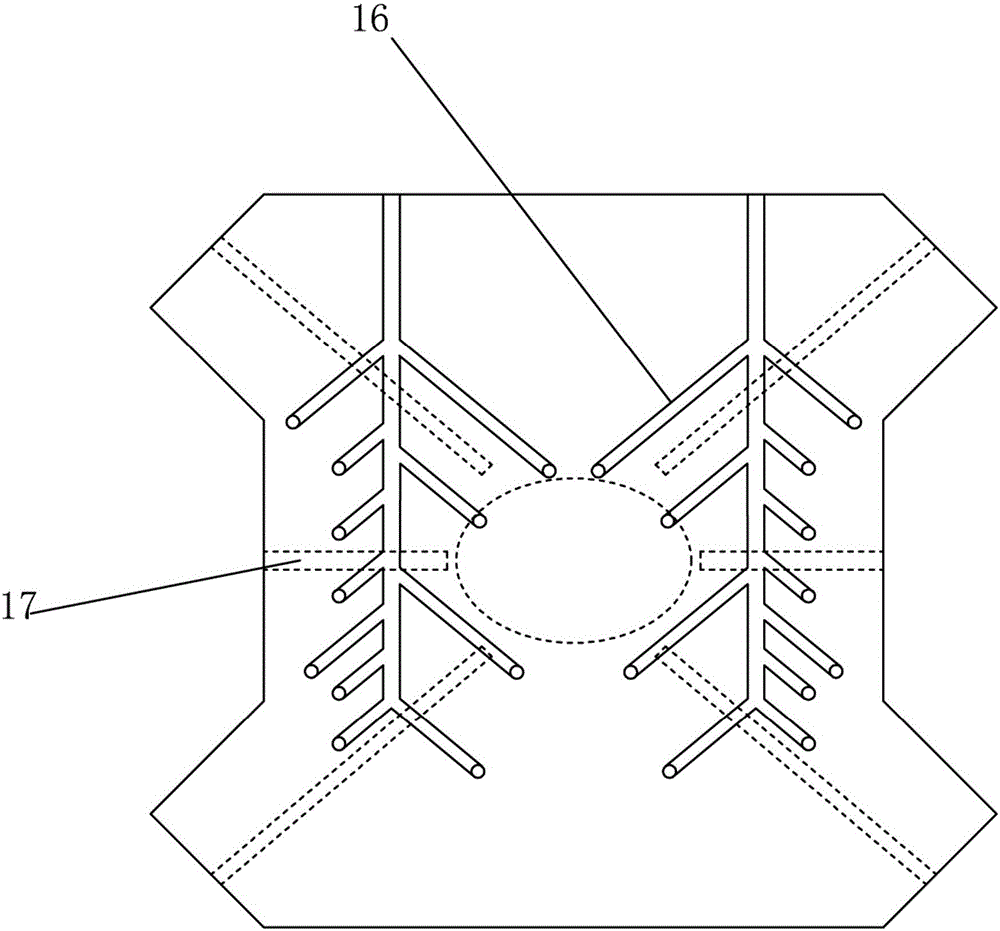

[0023] Embodiment: provide a kind of squirrel-cage motor rotor die-casting device, such as Figure 1-5 As shown, it includes a die-casting machine and a melting furnace. The die-casting machine is composed of a movable mold assembly, two replaceable mold assemblies, a fixed mold assembly and a pressure chamber mold inlaid combination. The movable mold assembly and the replaceable mold assembly Arranged with the fixed mold in sequence to form a closed cavity, the tail end of the pressure chamber mold passes through the fixed mold assembly and contacts with the closed cavity, a bracket is provided under the movable mold assembly, and the melting furnace includes An integrated crucible and low-frequency induction furnace. The heating power of the low-frequency induction furnace is 0-90KW. The movable mold assembly includes a body, a heat shield, a movable mold base, and a movable mold insert, which are arranged in sequence. The movable The mobile mold base is provided with a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com