Bidirectional disconnection type titanium alloy sheet spring

A thin-plate spring and titanium alloy technology, applied in low internal friction springs, drilling equipment, earthwork drilling and mining, etc., can solve problems such as relaxation or creep, and achieve the effects of convenient mass production, good performance, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

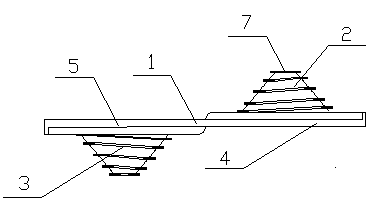

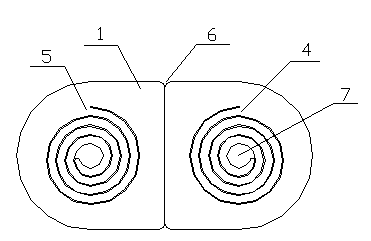

[0014] Such as figure 1 , 2 As shown, the two-way disconnected titanium alloy sheet spring provided by the present invention first grinds the titanium alloy sheet, so that the material surface after final processing has no obvious processing transition traces under 50 times magnification, and the obtained thickness is 0.5 mm titanium alloy flakes 1, titanium alloy flakes 1 with surface roughness ≤ 0.6 μm, flatness < 0.05 mm, and thickness tolerance ≤ 0.05 mm. The upper spiral cutting area 4 and the lower spiral cutting area 5 are set on the titanium alloy sheet 1, and the upper spiral cutting area 4 and the lower spiral cutting area 5 on the titanium alloy sheet 1 are simultaneously stretched by using the upper and lower bidirectional composite stretching dies , forming the upper helical spring 2 and the lower helical spring 3. Both ends of the titanium alloy sheet are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com