Casting method for Q1100D ultrahigh-strength steel

A casting method and ultra-high-strength steel technology, applied in the field of continuous casting in the metallurgical industry, to achieve the effect of reducing center segregation, lightening center segregation, and enlarging equiaxed crystals in the center of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The casting section is 2000×250.

[0034] Check the condition of the fan-shaped section before pouring. There is no water leakage in the fan-shaped section. If the nozzle is blocked, it must be replaced.

[0035] During casting, the Q1100D high-strength steel chemical composition and mass percentage of the present invention are as follows:

[0036] C: 0.16%, Si: 0.2%, Mn: 1.15%, P: 0.008%, S: 0.002%, Alt: 0.027%, Als: 0.025%, Nb: 0.025%, V: 0.055%, Ti: 0.02%, Cr: 0.25%, Mo: 0.6%, Ni: 0.35%, Ca: 0.0017%, B: 0.0015%, and the rest are Fe and unavoidable impurities.

[0037] The water flow rate of the crystallizer is 4300L / min, and the water volume of the narrow side is 370L / min. The water temperature of the crystallizer will fluctuate slightly, but it should be controlled at 35-38°C, so as to ensure that the heat flux in the crystallizer during casting is 1100-1200KW / m 2 , the heat flux in this range can ensure casting safety and no cracks.

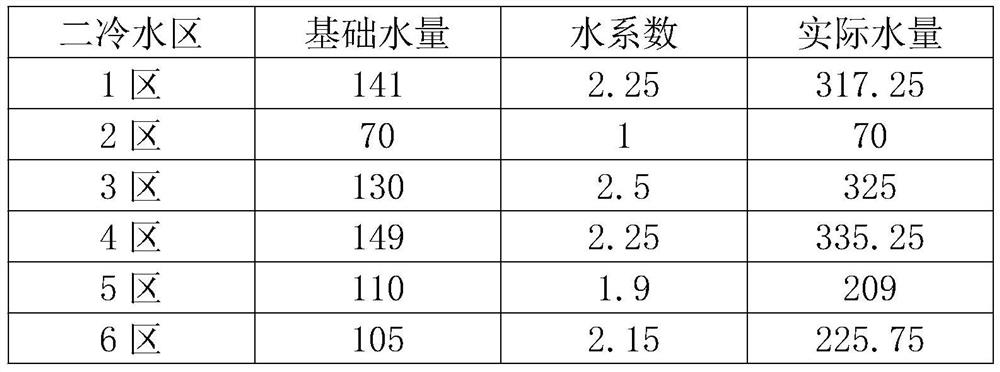

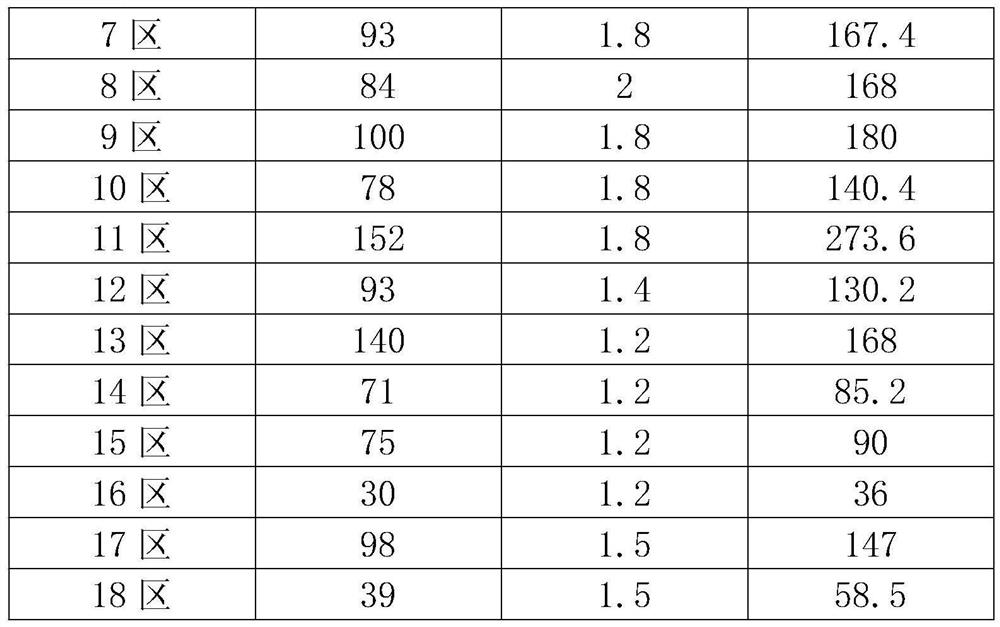

[0038] Since the water temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com