High-alkalinity and low-reactivity continuous casting mold flux for high-titanium steel and preparation method thereof

A technology of continuous casting mold flux and low reactivity, applied in the field of iron and steel smelting, can solve the problems that are not conducive to the continuous casting process, reduce the glassiness of mold flux, and burn the Ti element of molten steel, and achieve good surface quality of the casting billet. , to avoid the effect of large deterioration and reduction of vitreous

Active Publication Date: 2022-05-31

NORTHEASTERN UNIV LIAONING

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, without the addition of fluorine, the amount of crystal precipitation is small, and the heat transfer of the slag film is affected, which is not conducive to the continuous casting process

[0008] It can be seen that there are corresponding defects in the design of the above-mentioned mold flux, either by reducing the SiO 2 content to reduce the reactivity, but this method also reduces the glass property of the mold flux; either a large amount of perovskite may be produced in the continuous casting process, which affects the direct flow; or the reactivity of the mold flux is still high, and the molten steel Ti element burns seriously

So up to now, there is still no continuous casting mold flux that solves the above-mentioned technical problems.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

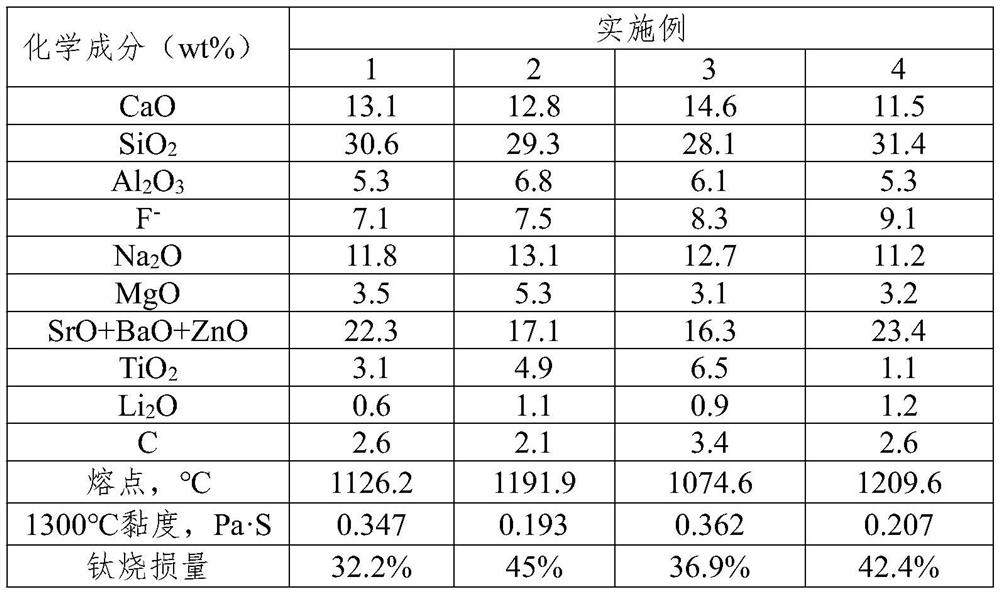

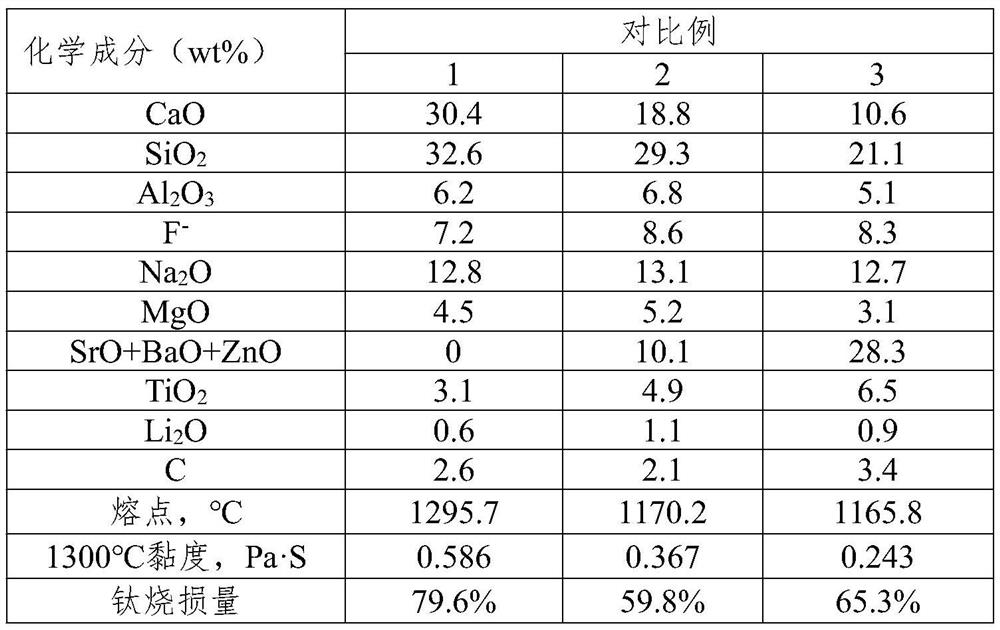

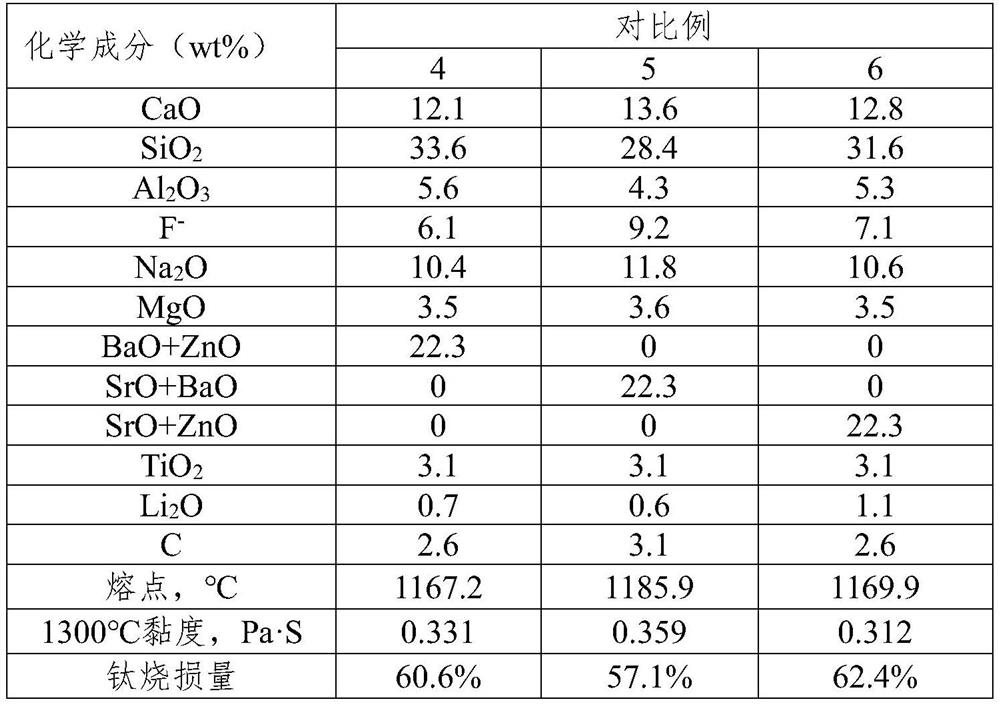

[0052]

[0057]

[0062]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a high-alkalinity and low-reactivity continuous casting mold flux for high-titanium steel, which comprises the following components in terms of mass fraction: CaO 10-17%, SiO 2 26~33%, Al 2 o 3 5~10%, F ‑ 5~10%,Na 2 O 10-15%, MgO 3-6%, (SrO+BaO+ZnO) 15-25%, TiO 2 1~10%, Li 2 O≤2%, C 2~5%, and the rest are unavoidable impurities. The present invention not only reduces SiO 2 activity, reduce the burning loss of Ti element in the continuous casting process; at the same time, it also inhibits the precipitation of high melting point perovskite crystals, ensures the glass property of the mold slag and the absorption capacity of inclusions, thereby reducing the surface quality of the slab.

Description

A kind of high basicity and low reactivity continuous casting mold powder for high titanium steel and preparation method thereof technical field The present invention relates to iron and steel smelting technical field, be specially high basicity low reactivity continuous casting mold slag for high titanium steel and thereof Preparation. Background technique Add the mold slag in the crystallizer, under the high heat environment created by molten steel, gradually heat up and sinter, melt to form a special The fixed melting structure enables it to exert its metallurgical function and ensure the continuous casting process and the quality of the casting billet. Mold powder crystallizes from adding The metallurgical functions performed by the process from the starter to the exit can be attributed to the following five categories: (1) prevent secondary oxidation of molten steel, (2) adiabatic heat preservation, (3) absorb non-metallic inclusions, (4) control the lubricatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D11/111

CPCB22D11/111Y02P10/20

Inventor 耿鑫侯昱李博洋姜周华王恩刚

Owner NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com