Special mold powder for continuous casting of titanium-containing high-strength welding wire steel and its manufacturing method

A technology of mold powder and a manufacturing method, applied in the field of iron and steel smelting, can solve problems such as the influence of operator's health on the service life of equipment, poor SiO2 reaction effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

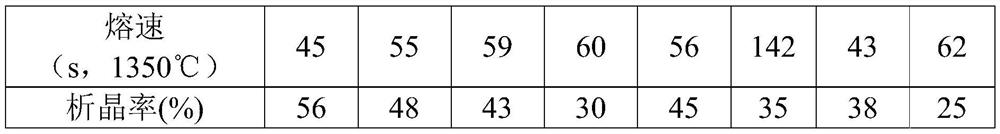

Examples

Embodiment 1

[0032] This embodiment provides a special mold flux for continuous casting of titanium-containing high-strength welding wire steel, which consists of the following components in terms of mass percentage:

[0033] CaO 28%, Al 2 o 3 28%, Na 2 O 6%, MgO 1%, F - 10%, B 2 o 3 10%, SiO 2 1%, TiO 2 10%, Fe 2 o 3 2%, carbon material 4%, the mass ratio of graphite and carbon black in the carbon material is 2:1.

[0034] This embodiment also provides a method for manufacturing the above mold flux for continuous casting of titanium-containing high-strength welding wire steel, including the following steps:

[0035] (1) Raw material preparation: weigh CaO and Al according to the above mass percentage 2 o 3 、Na 2 CO 3 , MgO, F - , B 2 o 3 , SiO 2 、TiO 2 and Fe 2 o 3 and carbon materials; where Na 2 CO 3 To generate Na after melting 2 O raw material, Na 2 CO 3 The mass according to Na 2 The mass conversion of O is obtained;

[0036] (2) Melting: uniformly mix ...

Embodiment 2

[0041] This embodiment provides a special mold powder for continuous casting of titanium-containing high-strength welding wire steel, which consists of the following components in mass percentage:

[0042] CaO 30%, Al 2 o 3 30%, Na 2 O 7%, MgO 2%, F - 8%, B 2 o 3 8%, SiO 2 2%, TiO 2 6%, Fe 2 o 3 1%, carbon material 6%, the mass ratio of graphite and carbon black in carbon material is 2:1.

[0043] The preparation method of this example is the same as that of Example 1, except that the heating temperature in step (2) of this example is 1350°C, and the heat preservation is 40min, and the water temperature of water quenching in step (3) is 5°C.

Embodiment 3

[0045] This embodiment provides a special mold powder for continuous casting of titanium-containing high-strength welding wire steel, which consists of the following components in mass percentage:

[0046] CaO 29%, Al 2 o 3 29%, Na 2 O 9%, MgO 3%, F - 6%, B 2 o 3 6%, SiO 2 4%, TiO 2 4%, Fe 2 o 3 2%, carbon material 8%, the mass ratio of graphite and carbon black in carbon material is 3:2.

[0047] The preparation method of this example is the same as that of Example 1, except that the heating temperature in step (2) of this example is 1450° C., and the water temperature for water quenching in step (3) is 15° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com