Production method for deep drawing high-carbon steel wire rod

A production method and carbon steel technology, applied in the field of metallurgy, can solve the problems of inability to eradicate reticular cementite on the surface of wire rods, high process costs, and economic losses, and achieve good surface quality of slabs, low production costs, and reduced growth. carbon effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

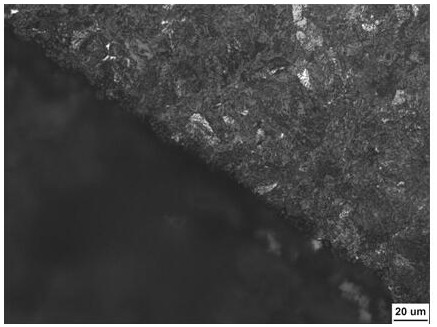

Image

Examples

Embodiment 1

[0018] Embodiment 1: The production method of the X82LB aluminum-clad steel wire rod of φ5.5 mm

[0019] The mass percentage of the chemical composition of the steel is C=0.85, Si=0.25, Mn=0.62, P=0.008, S=0.009, AlT=0.0008, and the balance is Fe and unavoidable impurities. Process and main parameters:

[0020] The converter is charged with 81 tons of molten iron, 15 tons of scrap steel, the end carbon is 0.07%, phosphorus is 0.006%, the fixed oxygen is 366PPM, and the tapping temperature is 1595°C. In the tapping process, slide double gears are used, 216kg of low-aluminum and low-titanium ferrosilicon, 260kg of manganese metal, 800kg of low-nitrogen carbon powder are added for alloying, 500kg of lime and 301kg of acidic slag adjusting agent are added to the top slag.

[0021] The LF furnace is standing for 85 minutes, adding 305kg of lime, 499kg of acidic slagging agent, 100kg of SiC, feeding 300m of carbon wire, adjusting the composition and adding 50 metal manganese, the c...

Embodiment 2

[0025] Embodiment 2: the production method of the high strength QS92Mn wire rod of 13mm

[0026] The mass percentage of chemical composition of steel is C=0.92, Si=0.24, Mn=0.85, P=0.009, S=0.004, Cr=0.32, and the balance is Fe and unavoidable impurities. Process and main parameters:

[0027] The converter is charged with 82 tons of molten iron, 14 tons of scrap steel, the end point carbon is 0.08%, phosphorus is 0.008%, the fixed oxygen is 311PPM, and the tapping temperature is 1598°C. In the tapping process, slide double gears are used, 216kg of low-aluminum and low-titanium ferrosilicon, 450kg of manganese metal, 910kg of low-nitrogen carbon powder are added for alloying, 502kg of lime and 302kg of acidic slag adjusting agent are added to the top slag.

[0028] The LF furnace was standing for 90 minutes, adding 301kg of lime, 502kg of acidic slagging agent, 120kg of SiC, feeding 360m of carbon wire, adjusting the composition and adding 62 metal manganese, the chemical comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com